Just my .02 looking at your drawing looks to be about a 8 hour run and you could use machinable wax or what we call butter board witch is machinable plastic both of witch would hold tight tolerance the butter board would be more stable for testing and would even work to create a mold from. finding a place to do the work would be the problem the wax can be found at Grizzly tooling and i think they may even have the butter board epoxy does not have a high shrinkage factor and can be reinforced with many things. we use cavasill due to its super fine gran size like baby powder.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

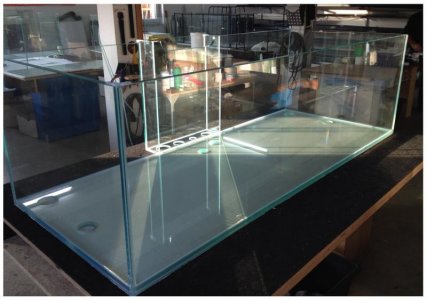

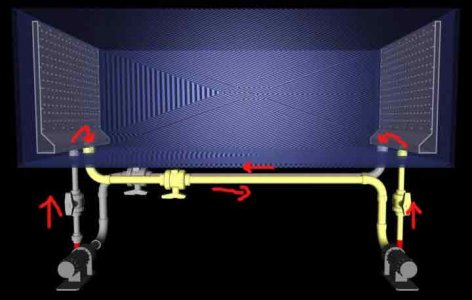

Large volume laminar flow machine

- Thread starter karimwassef

- Start date

karimwassef

Active member

I don't think a trolling motor is captive reef safe?

Was a suggestion as it looked as you would have the motors isolated from the main tank area. but at the same time you have a very good point as they do use some kind of oil in them i am sure.Wish I could help you with the machining but as I work for a large company it is not allowed.

Will look at some cost on the materials tomorrow and give you some idea of cost for that part of it looking at your drawing the whole thing could be done on a manual machine but would take some time to do as for cnc it has a lot of repetitive sequences that would make it go rather easy for cutter path.

Gorgok

New member

I don't think a trolling motor is captive reef safe?

I don't think an electric trolling motor is much different from an external pump in terms of pollutants. The motor is sealed, the shaft is most likely some stainless, and there are seals... Eventually the shafts will rust some, and seals may wear some ceramics into the tank. But i haven't had one apart to see if there are brass bushings or such.

Bigger problem with them is the form factor. They can't really be rotated in that narrow a space being so long, and while they can run in reverse its still a huge drop in efficiency over turning it around and running it forward.

And then you have to power them, with DC sources sometimes up to 60A for full power... Which also means quite heavy cables like 8 AWG.

I did some checking today with some co workers and one has access to a printer will need a STL. file of the parts you need run to give a good quote. He said he can do it for a reasonable fee as it is a private owned.And it is a high def machine. As for epoxy look at EpoxAmite is fairly reasonable at less than 100.00 for a gallon kit had to look it up as we get it by the drum. It does have a choice of activators and the slow will give almost a hour of pot life we have put as many as 10 layers of glass and reason and not have it get too hot to touch so should work.I hope this will help you and if the quote you get is what you are looking for I will get the two of you connected.

karimwassef

Active member

Ok. Send me a pm with your email address and I'll send the stl file

Did a small test today with the epoxamite had some beeswax so i used that and the temp never did get hot enough to melt it and without any glass in the mix it was almost clear but for a couple of bubbles but I did get a little carried away while mixing it. Stirred in a lot of air.

karimwassef

Active member

Got any pics?

Why do we want laminar flow? Is there reason to believe our corals and everything will like it? I know it probably looks cool.

Is alternating significantly needed or is a bulk continuous laminar high current flow a good step?

Not sure if this has been discussed or not, but once that flow hits the first rock or fish it will locally go turbulent.

Is alternating significantly needed or is a bulk continuous laminar high current flow a good step?

Not sure if this has been discussed or not, but once that flow hits the first rock or fish it will locally go turbulent.

karimwassef

Active member

It's been discussed earlier and some turbulence is normal, but if you start with turbulence, you end up with a chaotic flow.

When I snorkel or scuba on the reefs, I experience a pretty consistent bulk flow that is a wall of water moving in the same direction. It's not little jets of flow from PVC outlets or pump heads. The two flows are very different.

As far as alternating, it's is necessary IMO. There is never an extended flow in one direction on a real reef. It's always alternating. Nature operates in an alternating flow.

You don't inhale continuously from one direction and exhale in another... You inhale and then exhale. This is why you don't see sediment buildup like in a captive glass box. It's also why detritus doesn't settle.

It's a constantly dynamic but smooth experience.

This is my attempt at replicating nature. I came back from two weeks of daily reef snorkeling in Cancun and the flow in my reef just felt artificial. I already have a tremendous amount of alternating and surge flow... My tank is 8' x 3' and a double surge event raises my water level by 3" with four 2" PVC siphons actively pulling it into my massive double sumps!

It's just not the same...

When I snorkel or scuba on the reefs, I experience a pretty consistent bulk flow that is a wall of water moving in the same direction. It's not little jets of flow from PVC outlets or pump heads. The two flows are very different.

As far as alternating, it's is necessary IMO. There is never an extended flow in one direction on a real reef. It's always alternating. Nature operates in an alternating flow.

You don't inhale continuously from one direction and exhale in another... You inhale and then exhale. This is why you don't see sediment buildup like in a captive glass box. It's also why detritus doesn't settle.

It's a constantly dynamic but smooth experience.

This is my attempt at replicating nature. I came back from two weeks of daily reef snorkeling in Cancun and the flow in my reef just felt artificial. I already have a tremendous amount of alternating and surge flow... My tank is 8' x 3' and a double surge event raises my water level by 3" with four 2" PVC siphons actively pulling it into my massive double sumps!

It's just not the same...

karimwassef

Active member

Ideal can be tweaked with experience. As a first is rep, I'll duplicate what I personally experienced. That's where a flexible system adds value.

Klaus Jansen

.Registered Member

Similar threads

- Replies

- 1

- Views

- 245