You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Minimalistic multichip DIY LED build

- Thread starter maglofster

- Start date

To Lassef

To Lassef

@Lassef Here is the link to SF: some info on my first multiplecip led build and last build

http://www.saltvannsforum.no/forum/showthread.php?t=21044

To Lassef

@Lassef Here is the link to SF: some info on my first multiplecip led build and last build

http://www.saltvannsforum.no/forum/showthread.php?t=21044

Lassef

Member

Lasse,

I measured as close to the base of the chips as I could with my temp gun and I get between 111-121° F depending where exactly I point the laser.

Thanks,

Tony

You do not have any normal thermometer ? I usually use my wife's electronic meat thermometer

I do not trust temp gun´s if there is a reflecting surface - it should be black surface to give the right (or almost the right) temperature.

So there is no missunderstanding, take the temperature just at the joint between the chip and the heatsink. The chip itself emits some IR so if you use a temperature gun, it's easy to be the wrong temperature you scan.

What are your temperature 5 cm from the chip.

If you put your thumb just beside the chip - does it burn? - Not on the chip - it will burn !

Sincerely Lasse

hillscp

Soylent Green is People!!

No problems with changing the subject - and two reasons for that.

1) It seems that we agree

2) It is my favorite subject

I do not know the situation in USA but here i Sweden - the most popular "spot" lighting is done with 12 V of this type

People that sell replacment LED lamp for this is more or less criminal IMO. This because the same thing that we have discussed here earlier. This bulb is driven by a constant voltage source and if you put that type of drivers (with some exeptions) to a Power LED bulb - it will soner or later burn up. Belive me I did that with rather many 5 years ago

But during the last years there has been a change and replacment bulbs for the normal grid (in Sweden 230 V AC) has been more common. EU has banned the old Edison bulb in higher wattage so both Philips and Osram has wake up. Philips has a serie of spots and "Edison" bulbs that is very good and I realy think that the one that I have in my livingrom will be there for my grandchildren. But it cost about 80 $

Here in Sweden - we have a huge player according to furnishing and lifestyle - IKEA.

They have had a low profile in terms of LED general lighting but the last six months has introduced a product line in this area. A 5-watt spot for the normal grid cost around $10 and it give a better light than both halogen and compact fluourescents IMO. I have had some for 5 months now - we will see if the quality is good. But normaly - when IKEA introduce something new of this type - it change the market here in Sweden

In my job I start the replacement five years ago than now we nearly not install anything else than LED for general lighting and spot lighting. But we are very carefully with the quality (we do not use IKEA stuff) we can take that investment because most cost we have with the general lighting is replacment with new bulbs or fluorescent. If we can rise the life span with a coupple of years we save money and that we can do today with LED of the right quality.

Around 80 - 90 % of the LED Bulbs I installed 4 - 5 years ago i still working. I have change a lot of drivers in one type but on other hand I have changed 60 % of the electronic drivers for our fluorescent during the same time

Sincerely Lasse

If you were to wire a brand new house how would you do it? Wire each light circuit with it's own variable voltage CC power supply? What kind of luminaires are available for that sort of solution/design. The idea of retrofitting LED's with those PAR lamps seems silly to me for the very reason BeanAnimal mentioned. Each one has it's own power supply and that makes each one have an expensive SPOF.

Last edited:

Lassef

Member

What do you mean with SPOF - single poin of failure?

I think you misunderstood me. What I'm trying to say is that the replacement bulbs of the LED type that is intended for use in 12 volt halogen system usually does not work. They often get too much current and burn.

If I can pull down more than 50% of the power costs and reduce lamp replacements from 1-2 times per year to every 4-5 th year on average, I will be happy even if each source has its own power supply.

Sincerely Lasse

I think you misunderstood me. What I'm trying to say is that the replacement bulbs of the LED type that is intended for use in 12 volt halogen system usually does not work. They often get too much current and burn.

If I can pull down more than 50% of the power costs and reduce lamp replacements from 1-2 times per year to every 4-5 th year on average, I will be happy even if each source has its own power supply.

Sincerely Lasse

RockOn681

Member

I have read through this thread in essentially its entirety and am done acquiring all the other needed pieces to start a new 50 gallon cube, with the exception of the lighting. I am (somehow) still a little confused with the size chip or chips I should get for a 50 gallon. I think a single point source in the middle for day lighting would look best with some form of separated blues around the sides, but in terms of wattages to use I am lost. Any advice would be very appreciated so I can get started with this build. I am looking to be able to keep anything and of course will have the ability to dim the lights. Thanks

Ok, I haven't been following this as close lately, but is there now a different thread for the talk of the "dream chip" and getting people together on it. I know the continued discussion on the economics of it in this thread is now heresy. If there is other discussion going on about it, I'd like to follow it as well.

Ok, I haven't been following this as close lately, but is there now a different thread for the talk of the "dream chip" and getting people together on it. I know the continued discussion on the economics of it in this thread is now heresy. If there is other discussion going on about it, I'd like to follow it as well.

I agree, could someone PM me a link?

I agree, could someone PM me a link?

I dont think we can PM links to other sites. If Google is your friend im sure you can find it on your own.

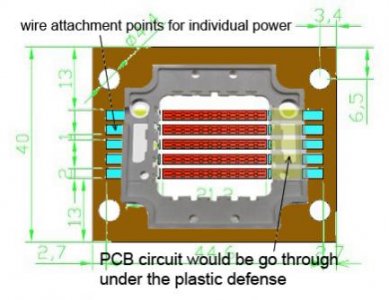

here is a drawing of the chip from the manufacturers which I stole from another forum where the group buy of the chip is being discussed.

Attachments

You do not have any normal thermometer ? I usually use my wife's electronic meat thermometer

I do not trust temp gun´s if there is a reflecting surface - it should be black surface to give the right (or almost the right) temperature.

So there is no missunderstanding, take the temperature just at the joint between the chip and the heatsink. The chip itself emits some IR so if you use a temperature gun, it's easy to be the wrong temperature you scan.

What are your temperature 5 cm from the chip.

If you put your thumb just beside the chip - does it burn? - Not on the chip - it will burn !

Sincerely Lasse

I dont have a manual thermometer. Ill get one though. I am able to put a thumb on both sides of the chip without burning my thumbs. It's hot but not to the point I have to remove my thumbs.

Tony

BeanAnimal

Premium Member

.....

I am not sure what any of that had to do with the basic point, and maybe maybe there is a misunderstanding about my "understanding". My grasp of the thermal properties of LEDs is just fine and as such I was not in need of an explanation

The point was that the differences in electrical efficiency between the different "chips" or for that matter 3W discretes is not really that relevant with regard to differences in the amount of heat we have to deal with. To that end, the differences in electrical efficiency at different drive currents is even less relevant to us. We can safely assume roughly 75% of the driven load is heat. Who cares if it si 71% or 78%. As such, OUR designs need to consider 100% (or more) of the driven load is heat. That gives is some wiggle room one way or the other. If we were producing fixtures for commercial consumption, then we would look at the situation from a different perspective that has to balance reliability and longevity with cost.

Or in other words, though there are differences in heat density per driven watt and/or device electrical efficiency they are all close enough that it does not matter. As such, we should design with worst case in mind so that we can avoid the complex analysis required to design in an optimized manner.

Last edited:

BeanAnimal

Premium Member

If you were to wire a brand new house how would you do it? Wire each light circuit with it's own variable voltage CC power supply? What kind of luminaires are available for that sort of solution/design. The idea of retrofitting LED's with those PAR lamps seems silly to me for the very reason BeanAnimal mentioned. Each one has it's own power supply and that makes each one have an expensive SPOF.

There will never be lamps to fit such wiring in a distributed situation. The power loss at low voltage (DC in this case) is insane. Line reactance and other issues come into play as well.

Lamps and fixtures will always have some type of CC drivwer built in. As times passes, the drivers will get smaller and more efficient and hopefully more reliable. Then again, the world ends this year so who cares

Lassef

Member

@lasse still trying to figure out how to cool this monster pendant. Also I'm doing this in steps i have actually 4 100watt suppose to be 2500k. ordered 4 hlg150h36b

If you mount the chip´s on a thick aluminumplate (I use 12 mm (0.5") - you can take thicker - 1" mayby) On the other side you mont one of these. You should fasten both chip and cooler with bolts and use a good thermal compound.

@ BeanAnimal: I agree - second time this day

Sincerely Lasse

The fact that you can keep your thumbs there suggests that temperature probibly is not too high. Assuming then that you are not welders or chef

Sincerely Lasse

Not a welder or a Chef Lol. Just an HVAC guy

Similar threads

- Replies

- 11

- Views

- 405