90 Upgrade and second test implementation

90 Upgrade and second test implementation

No doubt I was a little aggressive on the carbon and the size if the filter is very small, for sure but it was just a test to see if I could simulate the reaction described your your system. Having said that, i have an update:

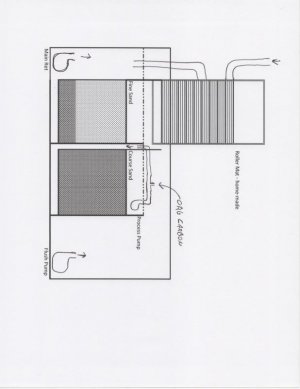

I decided to see if I could convert the existing sump in my 90 gallon tank to operate more like the sytem as described.

I was up against some limitations. First the home-made sump was only 16 inches deep and had a running depth of 12 inches, so I couldn't implement the sand bed exactly as described. Luckily, I had already been running a modified deep sand bed with two sets of stacked trays, each filled with about 1" of fine sand. In the old system, the water was allowed to pass from the bottom up and around each tray in order to maximize contact time.

I removed both sets of trays and installed two modified boxes. The first holds a combination of fine sand (5inches) and course, seperated by the drain sleeve. The second is all course sand / aragonite, (9 inches) for a total of 18 inches. Water flows up through both these sand beds, instead of from the top down.

I installed a main return pump on the left side. This pump runs all the time, returning the water that has been filtered by my home made Roller Mat, to the tank, through a check valve.

The second pump, on the right, is the "œflush" pump. It's basic function is to pull fresh water through the sand bed and return it to the tank. This pump currently runs, at most, 4 min per hour. I will explain how in a second.

Finally there is a process pump on top of the deep sand bed that returns water that has passed through the deep sand bed back to the bottom to start again. Organic carbon is also dosed into the flow path, when necessary, via a BRS 1.1ml/min dosing pump.

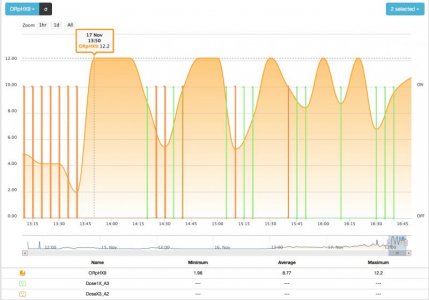

Using the Apex, I set up the following logic:

The process pump cycles on for three minutes and rests for two minutes, continuously.

I set two levels of carbon dosing:

Dose 1X (.11 ml, dosed every 5 min)

Dose 3X (.33 ml, doesed every 5 min)

I set three levels of ORP trip points:

ORP Low (ORP readings below -175 mV)

ORP Mid (ORP readings between +58 and -174 mV)

ORP High (ORP readings obove +59 mV)

Finally, four flush cycles:

Cycle 60 Turns on the flush return pump for 15 seconds, every hour.

Cycle 15 Turns on the flush return pump for 10 seconds, every 15 minutes.

Cycle 5 Turns on the flush return pump for 10 seconds, every 5 minutes.

Cycle High Turns on a second, 10 second flush return cycle, every 5 minutes.

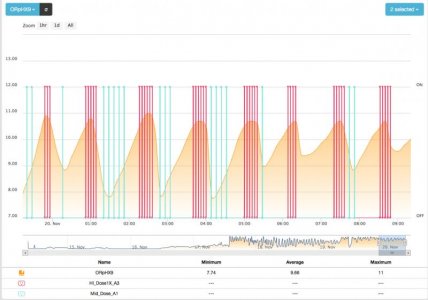

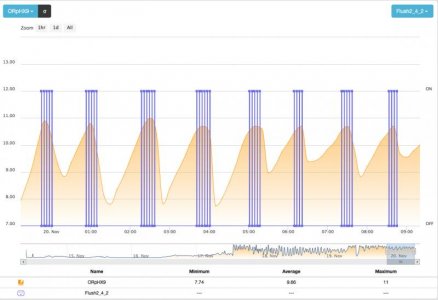

The logic is pretty simple:

If the ORP is High, then carbon is dosed at the 3X level every 5 min until the ORP reaches 58mV. Also, the Flush pump is only cycled once per hour during that period. This is the priming phase. The long rest periods are needed start the reaction.

Once the ORP reaches the mid-range, I reduce the dose to the 1X level and increase the Flush cycle to every 15 minutes.

Finally, once the ORP drops below -175mV, I stop dosing carbon and begin to cycle the Flush pump every five minutes. If the ORP continues to drop below -230 mV, I add the second Flush cycle during that 5 min period.

So far, everything seems to be working, as I would have anticipated. The ORP fluctuates from about +50mV to -300mV. I will see if I can tighten this up to stay in a more narrow range but since I really don't know what is the ideal zone, I am not too worried for now.

Aaron