Many would consider a 'normal' box to have holes on the side

There are no fixed rules as to depth; it depends on your setup, flow, pipe sizes, etc. Below are some general guidelines:

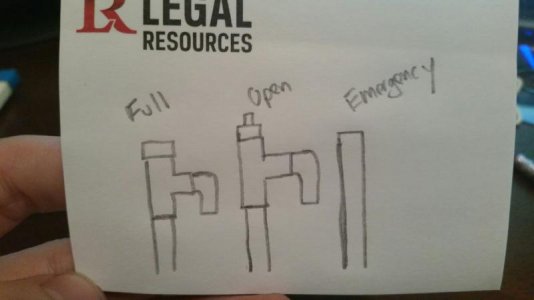

Siphon Standpipe:

For a full-depth overflow like you have, the siphon can be pretty much anywhere but there are a few things to keep in mind. If you have it too lose to the top, it will create a vortex and entrain air from the surface. This can occur even if you put an upside down 'U' on it so the opening faces down, it will just occur at a deeper level if it is facing up.

The higher you have it in the box, the more dead space you will have in the bottom of the box where water will tend to stagnate. The lower you have it in the box, the larger the volume of water that will drain down to the sump when the power is cut. Having it dow lower also gives you room to mount the durso-elbows on the open channel pipe.

In most side-mounted or coast to coast overflows, people place the downturned elbow fairly close (~¾") to the bottom of the overflow to minimize the risk of fish or snails getting into it. Frequently, there isn't enough room to do this in a full depth overflow. Maintenance is also more difficult simply because of the difficulty reaching all the way to the bottom.

Open Channel Pipe:

This ultimately determines the height of the water in the overflow box, so you should have it close to the top as to minimize splashing of the water as it flows into the overflow.

Dry Emergency Pipe:

This needs to be above the durso and below the lip of the frame. Typically on startup, the water level rises above the open channel to the level of the emergency and stays there a bit until the air is purged from the siphon. At this point, the siphon capacity increases and the water level drops to its steady state level. This process takes extra water from the return chamber in the sump. If your return chamber is smaller than the volume of water needed to raise the level up to the emergency pipe, you return pump will start to suck air and pump the display full of bubbles. Depending on the size of your display and size of your return chamber, having it lower than or at the same level as the overflow may be desirable.