rickztahone

New member

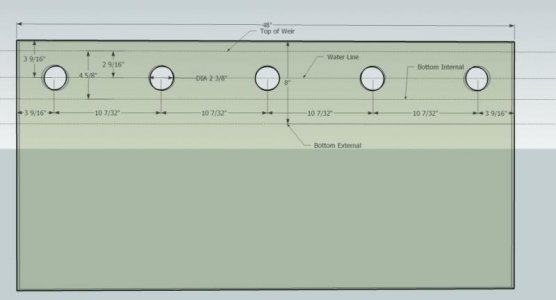

Just wanted to thank all of those that helped me out with my BA project. I did extensive research because I only wanted to do this once, and it came out perfect! From Floyd helping me through my acrylic fabrication overflows to Uncle giving me all the answers I needed step by step. Thanks again. Made a fun little video if you want to check it out. I should warn you ahead of time that it is a FW tank, not SW, but the idea is the same, minus the background

<iframe width="640" height="360" src="https://www.youtube.com/embed/NkVgAT0tLfI" frameborder="0" allowfullscreen></iframe>

<iframe width="640" height="360" src="https://www.youtube.com/embed/NkVgAT0tLfI" frameborder="0" allowfullscreen></iframe>