karimwassef

Active member

Once you get a fully mature screen, the algae will tend to want to grow into the slot/screen junction. When that happens it will divert flow to an area of less growth, which will then grow faster, diverting the flow away from it, etc...eventually the flow will be pretty balanced out. I don't know that I would spend a ton of time worrying about it right now, see if the issue persists. Unless of course, you happen to have bad OCD and a lot of free time.

hmmm I am working on keeping the OCD beasts at bay ...

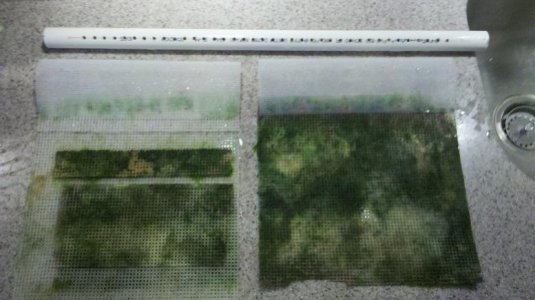

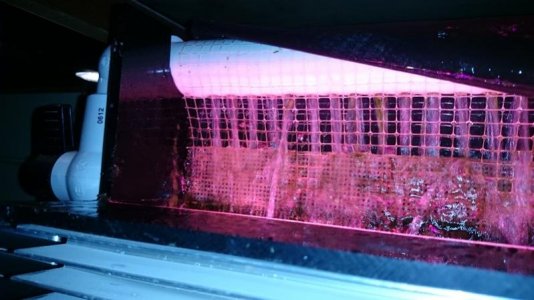

my second biggest pain is the spurting from the ends... basically, it turns at the T and then goes to the ends. The closest end to the T (yes I'm offset) ends up creating an "open pipe" flow down that PVC leg. I blocked it up with epoxy, so now it spurts out and runs down the leg instead of the screen.