Rhodophyta, while I appreciate that a plywood stand is possible, it may be outside the abilities of certain individuals. Also, if I understand your design, you rabbet the plywood panel between boards. To me, this is a more advanced technique then the spirit of this thread. Now, for my own personal tank, I am employing a mortise and tenon method for joining both the legs to the frames and the frame pieces to each other. While I respect that your design has several advantages over the one I present here, please be courteous of the fact that some of us do not have the tools, skills, or space to produce a stand such as your own and find the design presented in this thread to be within their abilities and meets their needs.RocketEngineer

This is not a plywood stand, which is certainly an OK way to build, but framing the plywood edges in solid wood pieces makes a stronger, straighter composite stand than either solid wood or plywood alone.

The tools, skills, and space to produce a rabbet or flush recess are simpler than those needed to produce a mortise and tenon. Both, in solid wood, are ancient woodworking techniques. All you need for a flush recess in the legs is a hand saw or a circular saw, two passes at right angles to each other. Mortise and tenon requires three tools - the saw, a chisel, and a drill - and many more cuts.

On the shelves, it is even simpler. What looks like a rabbet is made by gluing boards together with one dropped down to create the groove with no sawing or cutting at all. If you have never done a flush recess, it may be daunting to think about, but doing it is amazingly simple. It is well worth stepping out of the comfort zone of butting boards together to learn how to do it.

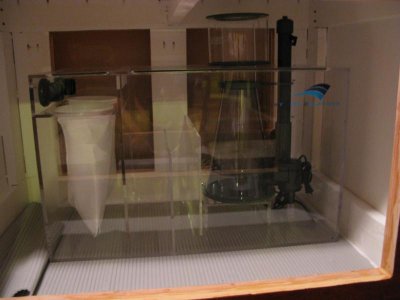

Another advantage of the composite stand besides strength and durability is that it takes up less wall space and has fewer obstructions and more working room around the tank relative to other designs. It is very flexible since you can either make it a double stand, triple stand, or "skin" it to create a cabinet style stand with space inside for a sump. Either way the design has a recess above the bottom shelf perfect for completely out-of-the-way twist bulb lighting for the bottom tank or a sump.

If you would be so kind as to post a link to a template which employs these more advanced woodworking methods to arrive at stands such as you show in the picture, I will be happy to distribute it as well as my own when asked for a template to work from. There are multiple ways to arrive at an acceptable stand. Each to their own preference and abilities.

RocketEngineer

I have no template, but I did write a math-free article demonstrating the techniques and leaving the stand size calculations to be customized by the builder. It is not so much an advanced technique as it is simply letting each kind of wood do what it is best at.

http://www.cichlid-forum.com/articles/diy_stand2.php

The materials list and cuts can be calculated with pencil and paper, or using a drafting program like autocad. Someone with your computer skills would probably create a programmed template that would produce the cutting dimensions and materials list for each size of tank.