owenspackman

New member

Rocketengineer or any other knowledgable stand builder. I need some assistance.

It has been brought to my attention that my stand may not be strong enough to support my tank and i need advice on whether this is true and what changes i need to make

The tank isa 180, 48x36x24. I designed the stand to have a 6" lip/shelf around the edge of the tank and this is where the question of strength has come on.

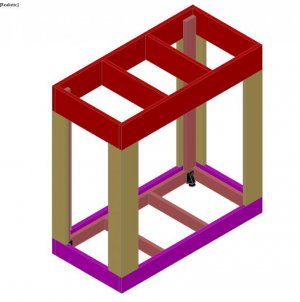

Here is the frame, the only change from this as it currently stands a 2x4 upright in the front and one in the back.

<a href="http://www.flickr.com/photos/29441159@N03/8484414918/" title="IMG_7312 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8086/8484414918_e6e57e0f1d.jpg" width="500" height="375" alt="IMG_7312"></a>

2x4 was added in front and rear.

<a href="http://www.flickr.com/photos/29441159@N03/8501162673/" title="DSC_0067 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8111/8501162673_c05c439e00.jpg" width="500" height="334" alt="DSC_0067"></a>

I started skinning and it now looks like this

<a href="http://www.flickr.com/photos/29441159@N03/8505730188/" title="DSC_0006 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8374/8505730188_ec42a8ef44.jpg" width="335" height="500" alt="DSC_0006"></a>

The tile layout shows where the tank will sit, 6" in from the sides and 6" from the font. The rear of the tank will sit along the back edge of the frame.

The concern seems to be that the tanks corners will not be sitting on the corners of the stand and have no support.

What needs to be done?!

Thanks in advance, this is the first time i've ever done a project such as this.

It has been brought to my attention that my stand may not be strong enough to support my tank and i need advice on whether this is true and what changes i need to make

The tank isa 180, 48x36x24. I designed the stand to have a 6" lip/shelf around the edge of the tank and this is where the question of strength has come on.

Here is the frame, the only change from this as it currently stands a 2x4 upright in the front and one in the back.

<a href="http://www.flickr.com/photos/29441159@N03/8484414918/" title="IMG_7312 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8086/8484414918_e6e57e0f1d.jpg" width="500" height="375" alt="IMG_7312"></a>

2x4 was added in front and rear.

<a href="http://www.flickr.com/photos/29441159@N03/8501162673/" title="DSC_0067 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8111/8501162673_c05c439e00.jpg" width="500" height="334" alt="DSC_0067"></a>

I started skinning and it now looks like this

<a href="http://www.flickr.com/photos/29441159@N03/8505730188/" title="DSC_0006 by owenspackman, on Flickr"><img src="http://farm9.staticflickr.com/8374/8505730188_ec42a8ef44.jpg" width="335" height="500" alt="DSC_0006"></a>

The tile layout shows where the tank will sit, 6" in from the sides and 6" from the font. The rear of the tank will sit along the back edge of the frame.

The concern seems to be that the tanks corners will not be sitting on the corners of the stand and have no support.

What needs to be done?!

Thanks in advance, this is the first time i've ever done a project such as this.