ok i am going to butt in here and put some of this to rest a 3/4 ply is just as strong as a 2by4 when on its eage as long as it is conpleatley under the top of the stand ! after building cabnuts for 10 years for tanks i have onley seen one not work and that was becouse of the person swiched tanks and went a lot taller

if the stand is properly built, changing the height of the tank would not matter...weight placed on the edge of plywood is not going to cause it to fail, especially if it has proper lateral support....but changing a 24x24x24 cube to 24x24x36 cube is not going to make the stand fail...nor would making it 48 tall...the ply is more then capable of the weight capacity (if constructed properly)

and for the ones that do not under stand this the new but not so new standerd on razed foundation homes is lament joices hence plywood with a 2 by 4 on each top amd bottom

what you are trying to describe with painful spelling errors are two different things, Laminate beams (para-lam) or laminate joists (LVL's) are completely different then TJI's (silent floor) joists..paralam's and LVL's dont have flanges on them, and TJI are constructed from OSB (orientated strand board) not plywood, and for the most part, the flanges are laminate ply construction and not 2x material.

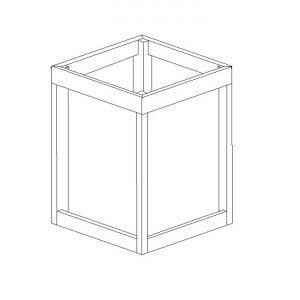

nobody is saying the plywood stand wont hold weight, we are saying there is no support for racking, the toe kick portion was not done correctly for the weight of a tank, and the top of the stand ( a piece of ply on its flat) will not hold up long with the weight of the tank being strictly held up by the edges of the ply and no centre support...properly built a stand doesnt need a plywood top, the tank should rest on the vertical supports.

I think you overkilled it and sacrificed some space and accessibility that you didn't want to and didn't have to.

i agree, there were much more elegant solutions posted to fix this stand...simply sacrificing 4" on the top of each door, and 1.5" on the verticals of each side of the door would have fixed this without sacrificing hardly any access to the sump...i would have glued 1.5" tall strips of cabinet grade ply to the underside of the top going across the stand...i then would have glued a 4" strip across the top of the door on the left side of the stand (the secondary access door) ensuring it was pressed and nailed in tightly to the bottom of the strips under the top... then i would have glued 2-3" wide strips up the corner of each door, ensuring they fit tightly between the floor and the 4" piece above the door, do the same to the other opposite side of the stand...i would then glue in a piece to the back of the one corner leg in the same fashion as the first, which would slightly reduce the opening of the front door...then i would flip the stand over, and put a bunch of strips of plywood behind the toe kicks, to transfer the loads of new post and beam construction of the stand directly to the floor...all you have sarcificed in this situation would have been ~2" in the interior height of the stand, ~3" in the width of the side door opening, ~ 4" in the height of the side door opening, and ~ 1-2" in the width of the front door opening. stain the pieces to match the stand and you would never know it was built otherwise.