kjonulak

New member

Goals:

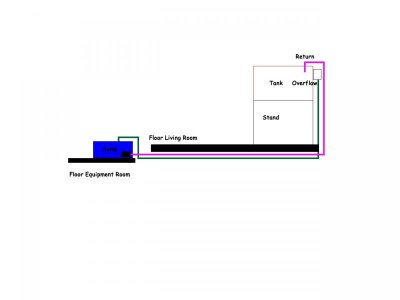

Remote sump in equipment room.

Quiet Overflow.

What is known:

Distance from tank to equipment room: 36 feet.

Floors will be concrete slab.

What can be changed:

Number of pipes from tank to equipment.

Size of pipes.

Material of pipe. (I was thinking high flex PVC tubing used in ponds. Advantage is no elbows, smooth surface inside tubing. Uses standard Schedule 40 fittings. Fittings can be glued to tubing.)

Floor height in equipment room. Right now builder was going to drop floor around 4-6 inches. He indicated he could make part of the floor 1 foot or more lower.

I don't have the tank or stand yet. Thinking of a 5'x3'x2' or 5'x3'x30". I would think the overflow would be ~5' off the floor level.

Option 1: 1 sump in equipment room.

What type of silencer can I use? Bean/Herbie/Durso/Stockman/Other?

What size should the drain line(s) and return line(s) be?

Would like to have a 150 gallon sump. How high for sump?

Depending on the silencer, where should the drain enter sump?

Option 2: 2 sumps, one under tank the other in equipment room.

Would this setup work? Why or why not?

I would like to use a Bean style which would drain into the sump 1. This would allow me to keep tank overflow quiet.

What size should the drain line(s) and return line(s) be? (overflow to Sump 1)

What size should the drain line(s) and return line(s) be? (Sump 1 to Sump 2)

Noise from Sump 1 to Sump 2?

Would like to have a 150 gallon sump. How high for sump?

What should the height difference be the 2 sumps?

Height of the pipe leaving Sump 1?

Where should the pipe from Sump 1 enter Sump 2?

To get more height between Sump 1 and Sump 2, I can raise Sump 1 and/or lower Sump 2.

Remote sump in equipment room.

Quiet Overflow.

What is known:

Distance from tank to equipment room: 36 feet.

Floors will be concrete slab.

What can be changed:

Number of pipes from tank to equipment.

Size of pipes.

Material of pipe. (I was thinking high flex PVC tubing used in ponds. Advantage is no elbows, smooth surface inside tubing. Uses standard Schedule 40 fittings. Fittings can be glued to tubing.)

Floor height in equipment room. Right now builder was going to drop floor around 4-6 inches. He indicated he could make part of the floor 1 foot or more lower.

I don't have the tank or stand yet. Thinking of a 5'x3'x2' or 5'x3'x30". I would think the overflow would be ~5' off the floor level.

Option 1: 1 sump in equipment room.

What type of silencer can I use? Bean/Herbie/Durso/Stockman/Other?

What size should the drain line(s) and return line(s) be?

Would like to have a 150 gallon sump. How high for sump?

Depending on the silencer, where should the drain enter sump?

Option 2: 2 sumps, one under tank the other in equipment room.

Would this setup work? Why or why not?

I would like to use a Bean style which would drain into the sump 1. This would allow me to keep tank overflow quiet.

What size should the drain line(s) and return line(s) be? (overflow to Sump 1)

What size should the drain line(s) and return line(s) be? (Sump 1 to Sump 2)

Noise from Sump 1 to Sump 2?

Would like to have a 150 gallon sump. How high for sump?

What should the height difference be the 2 sumps?

Height of the pipe leaving Sump 1?

Where should the pipe from Sump 1 enter Sump 2?

To get more height between Sump 1 and Sump 2, I can raise Sump 1 and/or lower Sump 2.