If u don’t have any bubbles exiting the syphon pipe then it more then likely has purged the air. The noise almost has to be eighther the open channel taking to much water or it’s the water entering the exterior box thru the pass thru holes. U need to figure out which one of the two it is, or it may be both.

To test it all u should need to do is turn the 90 on the open channel facing up so it isn’t taking any water at all. If that makes it quiet then the open channel is taking to much watet. If it’s still loud then it is the water coming thru the pass thru holes, so u would need to raise the water level in the exterior box. To do that u would need to slightly close the valve on the syphon to raise the water level. Usually the water level needs to be atleast 1/2 to 3/4 of the way up the pass thru holes for it to be quiet. If your holes are drilled lower then normal then u may find u can even have the pass thru holes submerged. Once u determine where the water level needs to be then u can set the hieght of the open channel so it is only taking a trickle of water.

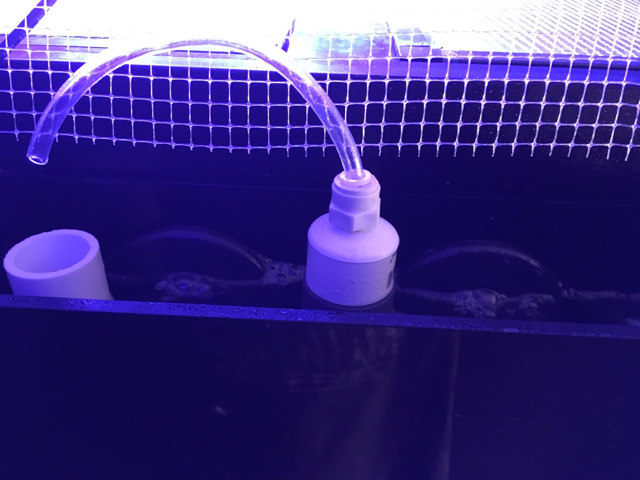

Sisterlimonpots photo is a good example of where the water level needs to be on the open channel, which is the pipe on the left. It can be a little less but any more then where it is in the picture & the open channel will be loud. So if u find the water level in the box has to be 3/4 of the way up the pass thru holes, then set that section of the open channel 3/4 of the way up on the pass thru holes

To test it all u should need to do is turn the 90 on the open channel facing up so it isn’t taking any water at all. If that makes it quiet then the open channel is taking to much watet. If it’s still loud then it is the water coming thru the pass thru holes, so u would need to raise the water level in the exterior box. To do that u would need to slightly close the valve on the syphon to raise the water level. Usually the water level needs to be atleast 1/2 to 3/4 of the way up the pass thru holes for it to be quiet. If your holes are drilled lower then normal then u may find u can even have the pass thru holes submerged. Once u determine where the water level needs to be then u can set the hieght of the open channel so it is only taking a trickle of water.

Sisterlimonpots photo is a good example of where the water level needs to be on the open channel, which is the pipe on the left. It can be a little less but any more then where it is in the picture & the open channel will be loud. So if u find the water level in the box has to be 3/4 of the way up the pass thru holes, then set that section of the open channel 3/4 of the way up on the pass thru holes

Last edited: