theatrus

100-mile-commuter

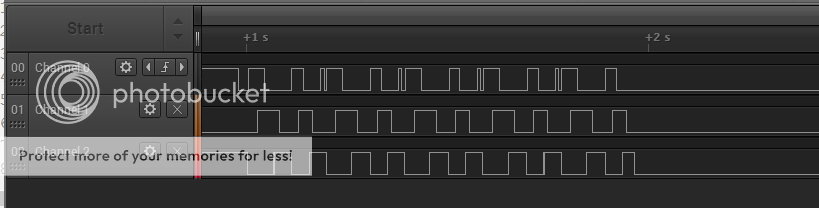

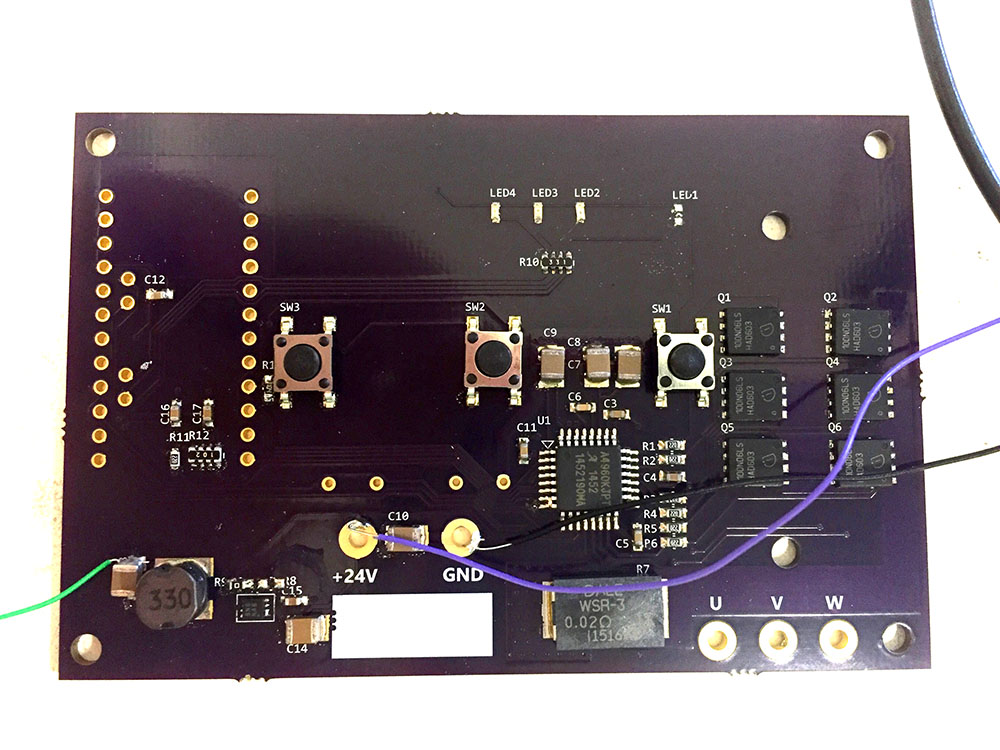

Yay! Making progress. Pumps spinning is a good sign of progress

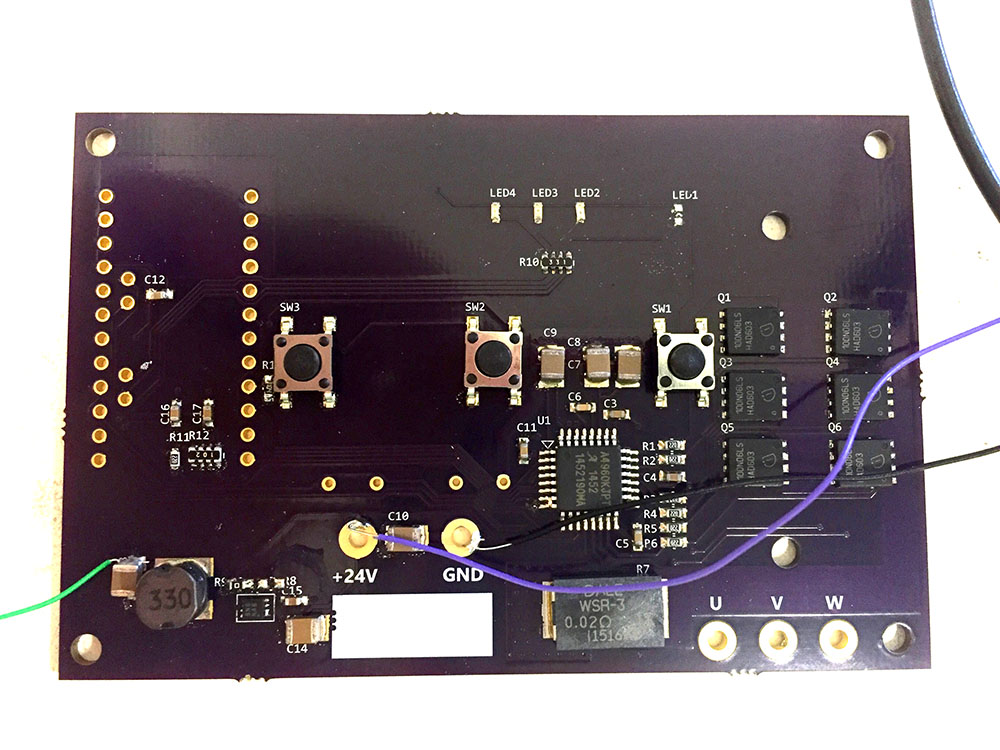

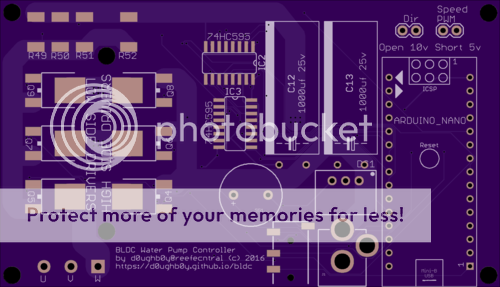

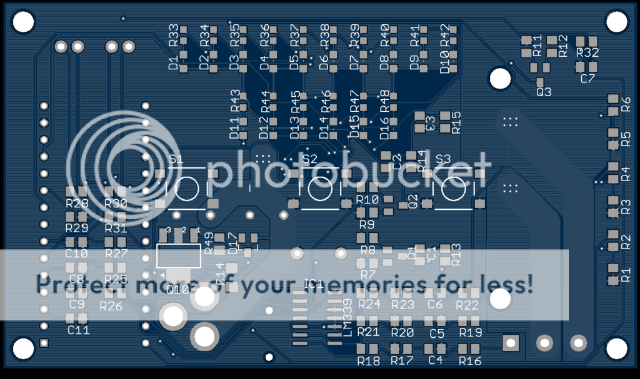

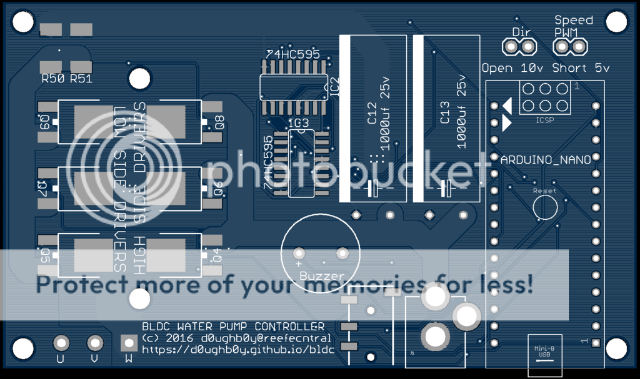

I only got so far as loading parts onto my controller board, and then being unable to find the matching Arduino board. Too many builds in progress between the LEDs, controllers, and mechanical parts. Upside: at least the 5V supply works.

I only got so far as loading parts onto my controller board, and then being unable to find the matching Arduino board. Too many builds in progress between the LEDs, controllers, and mechanical parts. Upside: at least the 5V supply works.