You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Low Country Reef Tank....one more final upgrade

- Thread starter SPotter

- Start date

SPotter

Active member

magic erasers huh? ill have to try that for my nano acrylic. Looks amazing btw

make sure you get the original ones. they don't have any cleaning chemicals on them.

SPotter

Active member

Steve,

I shut down my tank already, and might heading down Georgia soon.

I am thinking of a new 500G 8' X 40" X 30" after I moved.

What????? done with NJ? what part of georgia?

SPotter

Active member

A Low Country Reef Tank....one more final upgrade

Gyre pump warning....

I have been using this pump while the seals on my closed diverters are being upgraded. Let me start off by saying that it's a great pump and definitely moves a lot of water but if you have very small snails in your tank it be fatal to the gyre propellers. This is the 2nd time they have destroyed while in operation. I couldn't figure out what caused it the first time because there weren't any snail found inside of the cage. This time I was standing right in front of the tank when I heard this awful noise and within seconds this is what I was left with.

View attachment 302909

Coralvue has been great and will be sending a courtesy set of propellers but as long as I have these little snails in the tank I don't see how I can use this. This is a great product but if you have one and small snails....it could be problematic.

Gyre pump warning....

I have been using this pump while the seals on my closed diverters are being upgraded. Let me start off by saying that it's a great pump and definitely moves a lot of water but if you have very small snails in your tank it be fatal to the gyre propellers. This is the 2nd time they have destroyed while in operation. I couldn't figure out what caused it the first time because there weren't any snail found inside of the cage. This time I was standing right in front of the tank when I heard this awful noise and within seconds this is what I was left with.

View attachment 302909

Coralvue has been great and will be sending a courtesy set of propellers but as long as I have these little snails in the tank I don't see how I can use this. This is a great product but if you have one and small snails....it could be problematic.

Floyd R Turbo

Either busy or sleeping

Dang! Dwarf Ceriths are a staple in many tanks too. Man, that sucks. I have one, just waiting on a replacement controller. I dumped a bagful of DCs in a year ago but I don't see them crawling up the walls at night anymore so they must all be gone or burrowed deep.

I know it would kind of decrease performance, but what about wrapping the flow cages in a fine mesh netting, like bridal veil netting? That would keep anything beside the baby snails out I would think...maybe...

I know it would kind of decrease performance, but what about wrapping the flow cages in a fine mesh netting, like bridal veil netting? That would keep anything beside the baby snails out I would think...maybe...

Newbie Aquarist

Reefing is my middle name

Wow that's a killer(referring to the cerith snails destroying you pump). I use to have the when I first started my 225 gallon tank. They all ended up in my overflows or filter socks. Sorry that happened to you Steve.

Thanks for the post Steve. I have two Gyre pumps on my 300 gallon. Just yesterday all 4 propellers were broken and I didn't know why. Now I know why as I have DC as well. Gonna need something to prevent this from happening again. Because, if it happened to both pumps then it's only a matter of time before it happens to the backups I put in. I just contacted the company. They do have great customer service. And these pumps are amazing.

SPotter

Active member

Thanks for the post Steve. I have two Gyre pumps on my 300 gallon. Just yesterday all 4 propellers were broken and I didn't know why. Now I know why as I have DC as well. Gonna need something to prevent this from happening again. Because, if it happened to both pumps then it's only a matter of time before it happens to the backups I put in. I just contacted the company. They do have great customer service. And these pumps are amazing.

Well, I tried to get as many of the DC's out as I could and felt confident running the gyre again but when I came downstairs this morning to leave for work there was another awful sound coming from the pump. I didnt have time to inspect so I just shut it down and will look at it tonight when I get home. :uzi:

Floyd R Turbo

Either busy or sleeping

The motor is like any magnetic power head, so there are not directly connected parts. I can't imagine that a would cause any damage but the gyre is a bit different in that there is no continuous shaft from end to end. The flow cages have studs on both ends so you could end up with a magnet in the center section that is rolling around I suppose. You might check with support to find out what happens in this case, my first control unit wouldn't let me run it below 40%, it would error out and flash red after about 15 seconds so I think there is some kind of feedback or monitoring to see if the rotor is turning like it should, and if it is not, it stops the unit. I got a replacement control unit and ti now runs at 10% no problem, these units have a break-in period where the ceramic parts need to wear slightly and "seat"

Steve, what speed and setting do you have the pump set on? I just changed mine from 100%/alternating on and off every 3 hrs to both pumps being on all the time and set at 50%. I hoping with them being on all the time that the snails will stay out from the inside of the cage at night. Not an end all be all, but something needs to be done. I may try the window screen material as well, but it seems like it will be a big restrictive issue and the coming loose issue as well.

They really need to just make the slots on the cages narrower. I never had this issue with other pumps. May be because the slots are smaller or because the propellers are made of harder material in other pumps. Either way, this is going to be an issue for a lot of people.

They really need to just make the slots on the cages narrower. I never had this issue with other pumps. May be because the slots are smaller or because the propellers are made of harder material in other pumps. Either way, this is going to be an issue for a lot of people.

SPotter

Active member

A Low Country Reef Tank....one more final upgrade

I am running it at about 80%. I took it a part last night and couldnt find any obstructions that would be causing this crazy sound. Its fine when its dead silent out of the water but once its back in the tank it sounds like a muffled jack hammer. Im going to open another ticket with coralvue.

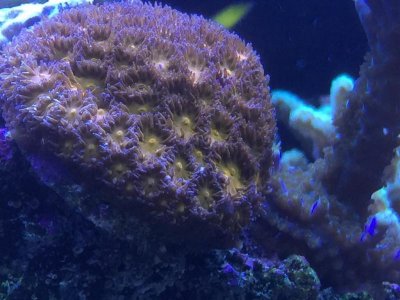

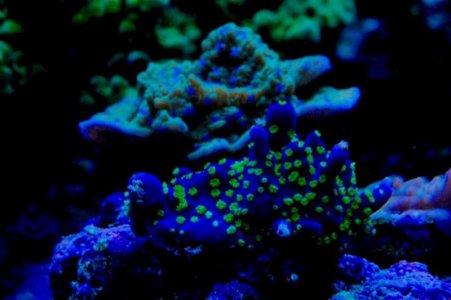

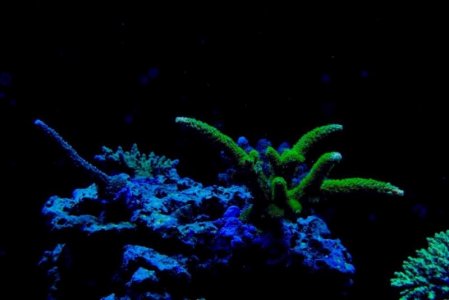

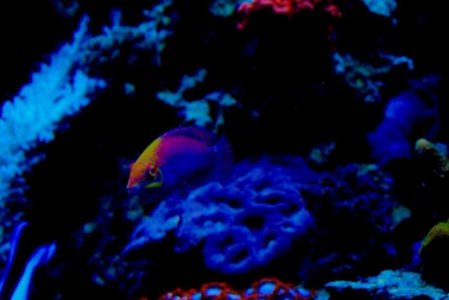

Lighting update....I decided to add a 4th mh pendant to my system. I love my pendants but they really spread the light out and was noticing dark spots. With that I decided to only run the t5's (4 x 54w pure actinic and 4 x 54w blue +) when the mh's are off. I took some quick par readings on the bottom after making the changes and I'm extremely pleased with the difference. Befor I was only getting 200-220 and now I'm getting 270-290. It's only been three days since making the change but I'm already noticing a huge difference in pe and coloration. I took the following pictures with just the mh's on and with my iPhone 6+. Amazing how much nicer the pictures come out when the t5's are off.

View attachment 303801

I am running it at about 80%. I took it a part last night and couldnt find any obstructions that would be causing this crazy sound. Its fine when its dead silent out of the water but once its back in the tank it sounds like a muffled jack hammer. Im going to open another ticket with coralvue.

Lighting update....I decided to add a 4th mh pendant to my system. I love my pendants but they really spread the light out and was noticing dark spots. With that I decided to only run the t5's (4 x 54w pure actinic and 4 x 54w blue +) when the mh's are off. I took some quick par readings on the bottom after making the changes and I'm extremely pleased with the difference. Befor I was only getting 200-220 and now I'm getting 270-290. It's only been three days since making the change but I'm already noticing a huge difference in pe and coloration. I took the following pictures with just the mh's on and with my iPhone 6+. Amazing how much nicer the pictures come out when the t5's are off.

View attachment 303801

Attachments

Similar threads

- Replies

- 2

- Views

- 310

- Replies

- 2

- Views

- 127