You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building 1600 Gallon Bioshock Themed Octopus Tank

- Thread starter krazyk148

- Start date

The MAX acr comes tomorrow. Pictures to follow  I used polyester resin with the fiberglass to answer your question. After the MAX acr is done ill finish with pentairs marine paint. (green and black)

I used polyester resin with the fiberglass to answer your question. After the MAX acr is done ill finish with pentairs marine paint. (green and black)

http://pentairaes.com/epoxy-paint-kits.html

http://pentairaes.com/epoxy-paint-kits.html

ReefsandGeeks

New member

I know others have commented that 1600gallons isn't enough for a LPO, but for reference, I just went to the Pittsburgh aquarium and they had a tank for a LPO that was fairly large and I estimated the tank to be a 6' cube, which is almost exactly 1600 gallons. Good luck with your build! been following since the beginning. Cant wait to see it filled up

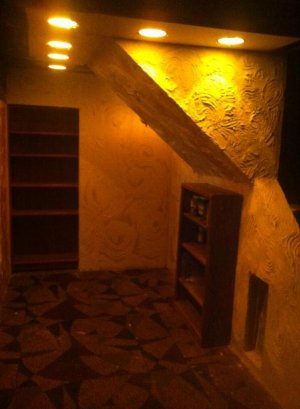

So finally got the MAX ACR epoxy in the other day and should be finished with the application this week. I bought 3 gallons (2 black and 1 white kit). My goal is to cover completely in white then cover in black to make sure i achieve full coverage. Im covering the inside and outside in the epoxy for added strength. Once this step is done then i can start the plumbing ( the sump is to the right behind the small bookshelf under the steps) and decorating in preparation for the acrylic panels

Attachments

Finished with the max acr epoxy this weekend (the front top and bottom that are still exposed have to stay that way until I get all 3 acrylic panels inside). I will say that the max acr is odorless and has great coverage so was pretty impressed. If I was going to do it again I probably wouldn't bother doing two colors since the black pigment worked so well. It's hard to see the contours of the tank right now so my apologies but when I get the green marine paint it should be much more noticeable.

The wall octo is coming along. I have to add the suckers next as soon as i figure out what looks like suction cups yet doesn't cost as much as actual suction cups haha. I'm thinking the bottom of k-cups or just making a mold and mass replicating them.

The wall octo is coming along. I have to add the suckers next as soon as i figure out what looks like suction cups yet doesn't cost as much as actual suction cups haha. I'm thinking the bottom of k-cups or just making a mold and mass replicating them.

Attachments

Rilelen

New member

Um, we are aware that there is no such thing as an "LPO", right? There is a GIANT Pacific Ocotopus, Enteroctopus dofleini. They are usually kept only by public aquariums and, at that, public aquariums located on the water that can utilize NSW systems for their absolutely MASSIVE filtration needs. For reference, my very small A. aculeatus has a 150g-rated skimmer on his 40g tank, and it's barely sufficient to keep up with the massive bioload, even with heavy water changes. They're incredibly messy eaters, on top of their tendency to shed suckers, etc. The Seattle Aquarium, which keeps GPO, brings in over 4000 gallons a DAY from the Puget Sound, which they then run through sand filters, etc.

As for the plan to raise this Giant Pacific Octopus from an egg...you are aware that this is a small egg species, and there are only a handful of documented cases of public aquaria raising one successfully from egg, through the larval stage into adulthood?

As for the plan to raise this Giant Pacific Octopus from an egg...you are aware that this is a small egg species, and there are only a handful of documented cases of public aquaria raising one successfully from egg, through the larval stage into adulthood?

mprygh

New member

Fun project!

I have done a couple of plywood sumps.

This one is only 40" high, but uses WAY less wood.

http://www.bareefers.org/forum/threads/plywood-120g-sump-about-150.10015/

I have also built a few more complex things with epoxy, like a catamaran.

(fiberglass foam sandwich)

I have to admit, looking at the first page with crayon drawings and

the Lincoln Log type build, I thought it was an April fools joke also.

But once the extra skins went on the outside, no worries except if it leaks.

Glad to see you continued the build through the negativity.

I think you did exactly the right thing on sanding between coats on the inside.

Even if it was perhaps by accident.

Key for the inner layers of epoxy/fiberglass is to be water tight.

They do almost nothing structurally.

Key to that is to get rid of those annoying little bubbles that form. It is amazing how much water can seep through those.

IMO: Best way is a bit of sanding. It scrapes off the top of the bubble, allowing the next coat of epoxy to fill it.

Although some people swear by using flame. Eh..

I do have one suggestion though:

Consider puttiing a few strips of glass on the outside, below each opening.

Say a strip 8 inches high, all the way across, a few layers of good woven.

That joint between plywood and acrylic has high risk of leakage, and has (literally) a ton of load at the bottom.

Those extra layers on the outside would make it super-strong and if it leaks there, you are not relying on the wood.

I have done a couple of plywood sumps.

This one is only 40" high, but uses WAY less wood.

http://www.bareefers.org/forum/threads/plywood-120g-sump-about-150.10015/

I have also built a few more complex things with epoxy, like a catamaran.

(fiberglass foam sandwich)

I have to admit, looking at the first page with crayon drawings and

the Lincoln Log type build, I thought it was an April fools joke also.

But once the extra skins went on the outside, no worries except if it leaks.

Glad to see you continued the build through the negativity.

I think you did exactly the right thing on sanding between coats on the inside.

Even if it was perhaps by accident.

Key for the inner layers of epoxy/fiberglass is to be water tight.

They do almost nothing structurally.

Key to that is to get rid of those annoying little bubbles that form. It is amazing how much water can seep through those.

IMO: Best way is a bit of sanding. It scrapes off the top of the bubble, allowing the next coat of epoxy to fill it.

Although some people swear by using flame. Eh..

I do have one suggestion though:

Consider puttiing a few strips of glass on the outside, below each opening.

Say a strip 8 inches high, all the way across, a few layers of good woven.

That joint between plywood and acrylic has high risk of leakage, and has (literally) a ton of load at the bottom.

Those extra layers on the outside would make it super-strong and if it leaks there, you are not relying on the wood.

Haha yeah the wood was mostly free so I had no problem doing the stacked build.

Yeah I kinda had to sand between each coat due to the angles involved. Your thoughts on sanding the micro bubbles was exactly how i planned on assuring maximum coverage.

Its hard to see from the pictures but i fiberglassed every angle to the outside of the aquarium and including the outside surrounds and corners. The window seats i used extra glass on just to insure a good seal when it comes time to applying the silicone gasket. Thank you for the good advice! I just ordered another MAX ACR kit and the Dark Green marine paint. Then i can start decorating it and setting up the plumbing

Yeah I kinda had to sand between each coat due to the angles involved. Your thoughts on sanding the micro bubbles was exactly how i planned on assuring maximum coverage.

Its hard to see from the pictures but i fiberglassed every angle to the outside of the aquarium and including the outside surrounds and corners. The window seats i used extra glass on just to insure a good seal when it comes time to applying the silicone gasket. Thank you for the good advice! I just ordered another MAX ACR kit and the Dark Green marine paint. Then i can start decorating it and setting up the plumbing

der_wille_zur_macht

Team RC

In life, everyone has to make their own "risk assessment" when it comes to deciding what projects to take on. I can understand some of the thoughts from the naysayers but personally I'm a huge fan of this build. Probably because I just really enjoy seeing people do things way outside of the norm. There's a billion cookie-cutter tanks on the internet, congrats for doing something different. Following this thread is probably the main reason why I've been checking this forum more often lately after a few years of absence, I hope you continue with the updates regardless of the commentary or outcome.

Thanks for the support Der wille  It should start to speed up now that the hard part is done. Im hoping to purchase the acrylic windows later this summer but will be updating as i decorate and plumb the tank. I enjoy stepping outside of the norm its where innovation is made!

It should start to speed up now that the hard part is done. Im hoping to purchase the acrylic windows later this summer but will be updating as i decorate and plumb the tank. I enjoy stepping outside of the norm its where innovation is made!

jphayes921

New member

Dad always said. Go for it. Can always start over. I think the idea is sweet. Plus I love Bioshock. Wife would probably leave if I did this.... Maybe hahaha. Go for it.

Sent from my Nexus 6 using Tapatalk

Sent from my Nexus 6 using Tapatalk

Similar threads

- Replies

- 0

- Views

- 312

- Replies

- 4

- Views

- 932

- Replies

- 0

- Views

- 2K

- Replies

- 13

- Views

- 5K