hazmat319

New member

hazmat319,

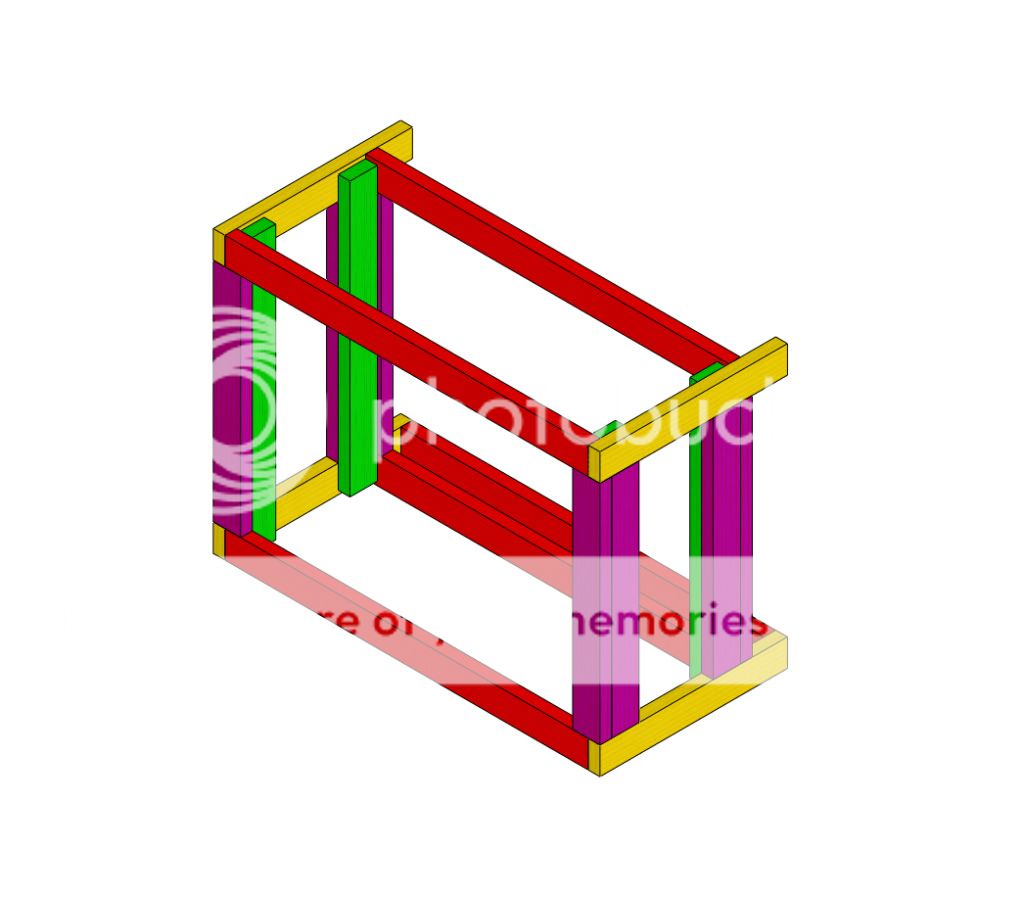

This is the solution I have come up with for this problem:

The idea is to use the end boards to cover the gap behind the stand. Another option is to install a vertical board behind the stand to hide everything. If you made it removable, you could get access for running wires but still have the clean look.

RocketEngineer

I want to make sure I understand this.

So, basically what you are doing is using the original 48x18 frame but then adding the extra space towards the back of the stand (like a porch addition

Hope that even makes sense! Is that correct?

Thanks for replying to my message.

Edit: Is it dangerous to sit a tank on a bigger stand? Wondering because like I said I have seen it done a few times with members of our group. Where does the risk come in? That the top will take on the weight and not the corners?