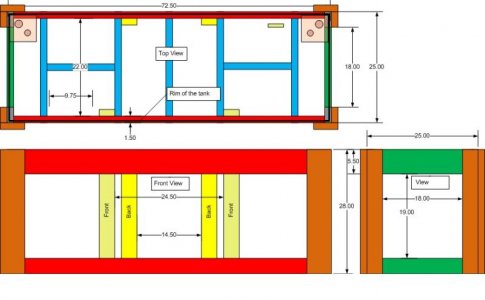

Rocket Engineer: I need to build a stand for a 215 Oceanic Ultimate, (72" x 24" x 29"), I am planning for an inwall installation. Based on your plans I would need 2x8's for the top portion, (yellow and red), would it be beneficial to also use 2x8's or 2x6's on the purple support areas? or would 2x4's suffice? I'd like to sleep at night. Everything else would be 2x4"s? Please confirm and thanks this thread is a great help.

Frank

Frank