You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Stands Template and Calculator

- Thread starter JohnL

- Start date

Also, what kind of plywood should I use for the top of my stand? Lowes has either Oak, Birch, or Blondewood. I planned on getting 3/4" plywood for the top with foam since my tank has no rim.

Whatever is cheapest.

The Oak, Birch, or Blondewood is only a veneer and generally only on one side, doesn't effect anything other than look.

Rhodophyta

New member

I prefer MDO (medium density overlay) coated both sides because it is flat, stiffer than other plywood, and waterproof.Whatever is cheapest.

The Oak, Birch, or Blondewood is only a veneer and generally only on one side, doesn't effect anything other than look.

I prefer MDO (medium density overlay) coated both sides because it is flat, stiffer than other plywood, and waterproof.

It's no stronger for what is needed under a glass tank. And the edges are still not waterproof, and that is the part that will get wet the easiest.

The normal plywood I buy is flat, I'd shop somewhere else if the stuff you get isn't. The MDO is smoother.... but so what, it makes zero difference especially with Styrofoam on it.

Rhodophyta

New member

The edges and interior of MDO are waterproof. In tests it's been submerged unpainted for over a year in saltwater and still looked new. Exterior and marine grade plywood are not as flat as MDO. It is stiffer and so sags less but is only slightly stronger than marine.Yes you could make do without the extra safety margin of stiffness and flatness and the smooth surface is covered with foam. But moisture easily builds up under the tank and the downgrades from MDO can swell and stress the tank.It's no stronger for what is needed under a glass tank. And the edges are still not waterproof, and that is the part that will get wet the easiest.

The normal plywood I buy is flat, I'd shop somewhere else if the stuff you get isn't. The MDO is smoother.... but so what, it makes zero difference especially with Styrofoam on it.

The edges and interior of MDO are waterproof. In tests it's been submerged unpainted for over a year in saltwater and still looked new. Exterior and marine grade plywood are not as flat as MDO. It is stiffer and so sags less but is only slightly stronger than marine.Yes you could make do without the extra safety margin of stiffness and flatness and the smooth surface is covered with foam. But moisture easily builds up under the tank and the downgrades from MDO can swell and stress the tank.

Actually I think tungsten should just be used, solid block, and 60' pilings under it.....

I doubt he has a 4x8 tank, there will be exposed edges. I have some huge doubts that water could get under the styrofoam with the weight of a tank on it. Hell in my garage water didn't get under a small piece of foam that I had a few pounds of tools on even.

The glass does not need complete support either. It does not need to be perfectly smooth either, and at 3/4 thick it doesn't matter what kind of wood you use it will bend to however flat the rest of your stand is.

I'd be more worried about the legs swelling more than plywood under the tank.

A 3/4 MDO sheet of plywood is $84 here, and there is only 3 sheet in the city at HD. Single sided MDO is $68.

Normal 3/4 plywood, $27

It is a very unneeded expense. A can of paint for the whole stand would be cheaper and far more useful overall.

Rhodophyta

New member

If it's that expensive where you are, then the paint is a good alternative, not the titanium, LOL. As a fish club member I've been in lots of fish rooms, and seen more problems with plywood swelling than with legs. And lots of failing bracing to tangent.Actually I think tungsten should just be used, solid block, and 60' pilings under it.....

I doubt he has a 4x8 tank, there will be exposed edges. I have some huge doubts that water could get under the styrofoam with the weight of a tank on it. Hell in my garage water didn't get under a small piece of foam that I had a few pounds of tools on even.

The glass does not need complete support either. It does not need to be perfectly smooth either, and at 3/4 thick it doesn't matter what kind of wood you use it will bend to however flat the rest of your stand is.

I'd be more worried about the legs swelling more than plywood under the tank.

A 3/4 MDO sheet of plywood is $84 here, and there is only 3 sheet in the city at HD. Single sided MDO is $68.

Normal 3/4 plywood, $27

It is a very unneeded expense. A can of paint for the whole stand would be cheaper and far more useful overall.

RocketEngineer

Space is big.

hi

i have added a double 2x6 on the top and double 2x4 on the bottom

tank is 2500x1000x600 and stand is 2800x1000x1000

is this ok? tank will rest on the main legs

Given the number of legs you have you don't need to double up either. As the tank sits directly over the legs, you have good load transfer. The other boards don't get the same support so aren't really helping.

dallasg

Reefing from South Africa

Given the number of legs you have you don't need to double up either. As the tank sits directly over the legs, you have good load transfer. The other boards don't get the same support so aren't really helping.

Thanks, start building this weekend

First post here, and I spent the greater part of my work day going through all of your posts, comments, answers, ideas.

I don't plan on starting this build concept until next year due to lots of planning needed. The end result is actually going to be a Wet Bar, but the aquarium is probably the most difficult... so I'm starting there.

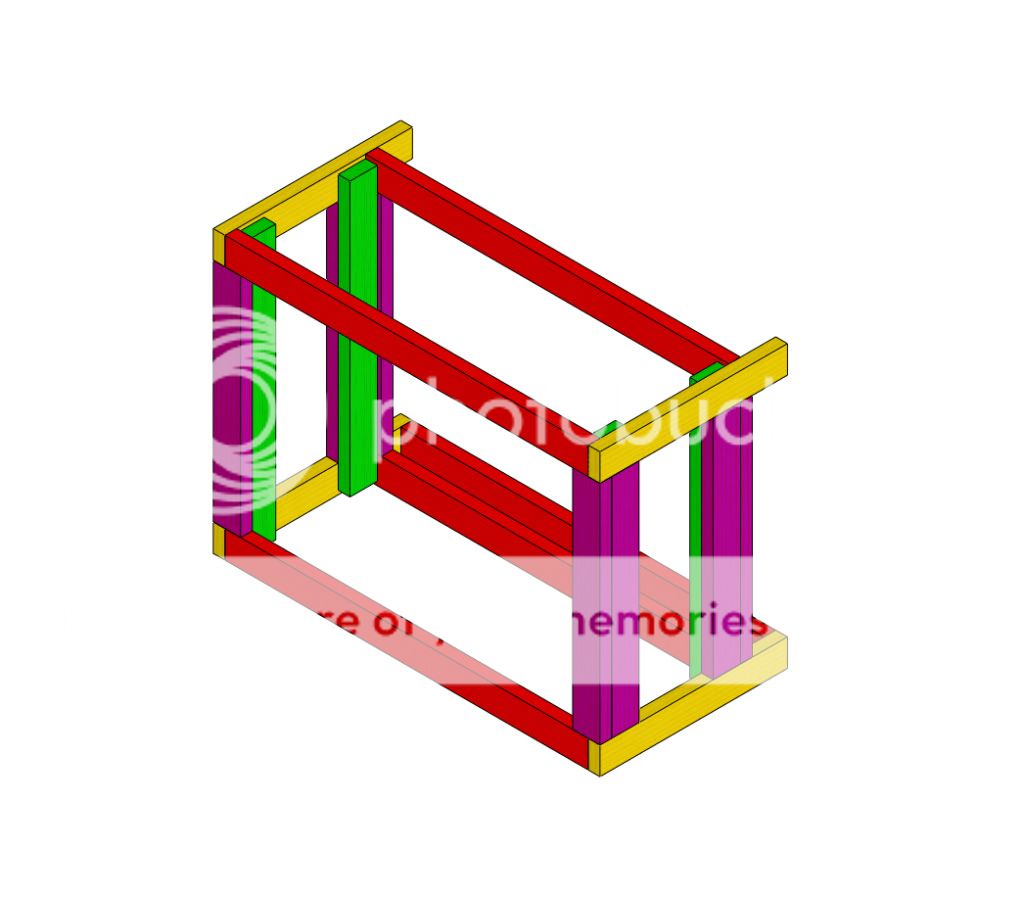

First things first, I'd like a 'thumbs up' on the aquarium stand design (see image). The white posts are 2x8" and the rest is 2x4" -- I marked the red 2x4s to help me see where the actual stress might be. I'm no engineer, so I'm just using what I think should happen.

The dimensions are in the image, but end result will be 96"x30"x30" -- the aquarium will be a plywood build, basically same dimensions: 96"x30"x20" (not completely set on the 20" yet, may bump to max 25" depending on bar material I end up using)

My main concern is this will be a bar (at home). As in, drunk people... I'd need to beef it up so that getting fallen on won't result in a failure. I think what I have designed should be enough, but I'm not an engineer what-so-ever, I'm basing my design off of others that I've seen.

I'm all for over-building.... I'd rather not have 200-300 gallons of water flooding the hardwood floors... my wife, well, I wouldn't be around anymore, lets put it that way, lol.

I appreciate any help / comments / questions!

I don't plan on starting this build concept until next year due to lots of planning needed. The end result is actually going to be a Wet Bar, but the aquarium is probably the most difficult... so I'm starting there.

First things first, I'd like a 'thumbs up' on the aquarium stand design (see image). The white posts are 2x8" and the rest is 2x4" -- I marked the red 2x4s to help me see where the actual stress might be. I'm no engineer, so I'm just using what I think should happen.

The dimensions are in the image, but end result will be 96"x30"x30" -- the aquarium will be a plywood build, basically same dimensions: 96"x30"x20" (not completely set on the 20" yet, may bump to max 25" depending on bar material I end up using)

My main concern is this will be a bar (at home). As in, drunk people... I'd need to beef it up so that getting fallen on won't result in a failure. I think what I have designed should be enough, but I'm not an engineer what-so-ever, I'm basing my design off of others that I've seen.

I'm all for over-building.... I'd rather not have 200-300 gallons of water flooding the hardwood floors... my wife, well, I wouldn't be around anymore, lets put it that way, lol.

I appreciate any help / comments / questions!

Last edited:

The stand being wider isn't an issue as long as you have supports directly under the edges. The best way to do this would be to extend the "ends" of the stand so to support the extra width. If the long boards are moved inside of the ends, then all four sides of the tank can be supported properly.

By extending the yellow boards, you can extend the stand either way. Just make sure the top frame is 2X8 for the size tank you mentioned.

HTH,

RocketEngineer

Hi RocketEngineer

Can I have the Bottom base(one long side) be wider then the top? my tank is 24 inches wide but the sump I'm going to use is 36 inches wide.....Hope this makes sense...

nanolover80

New member

Grnrado, how long did this take to put together and what was your cost .. btw i love it.

RocketEngineer

Space is big.

Indusrty, Given the size of the lumber and tank, you should be fine.

Foam is only needed if the tank has glass touching the plywood. If there is plastic trim under the glass, you don't use foam. The foam is there to eliminate point loads on the glass, not level the tank.

RocketEngineer

Foam is only needed if the tank has glass touching the plywood. If there is plastic trim under the glass, you don't use foam. The foam is there to eliminate point loads on the glass, not level the tank.

RocketEngineer

Grnrado, how long did this take to put together and what was your cost .. btw i love it.

Thanks. It took about a month doing work only one day a week. Total cost about $170. We used 2x6 boards and ripped them to perfect 2x4s for the structure. i will say that this thing is solid, and indeed over built. It is a wonderful stand but if I had to do it again, I would of used 1x2s for the structure. The 3/4" board wraps the whole stand and is more than enough to hold a biocube. I actually removed the back chambers of the biocube and drilled the tank for overflow and return with a sump below. I intend to install a pull out shelf for the sump to make maintenance super simple.

Similar threads

- Replies

- 1

- Views

- 324

- Replies

- 0

- Views

- 107