GROSSR

Active member

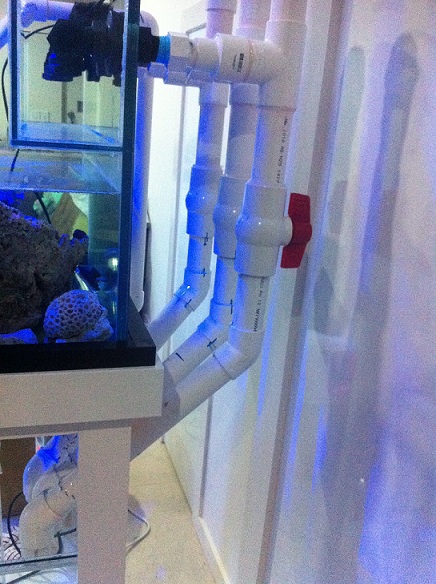

While I like this to restrict critters, snails, I am curious how much are you might be restricting flow. As long as you can take if off easily, you can always cut it down.

Try it out and if you think the flow is restricted, you can trim the elbow. Another thought is to turn the elbow so you get one side higher and allow more water to flow.

With that much clearance, will the elbow come off?

rich

Try it out and if you think the flow is restricted, you can trim the elbow. Another thought is to turn the elbow so you get one side higher and allow more water to flow.

With that much clearance, will the elbow come off?

rich