DavidinGA

Active member

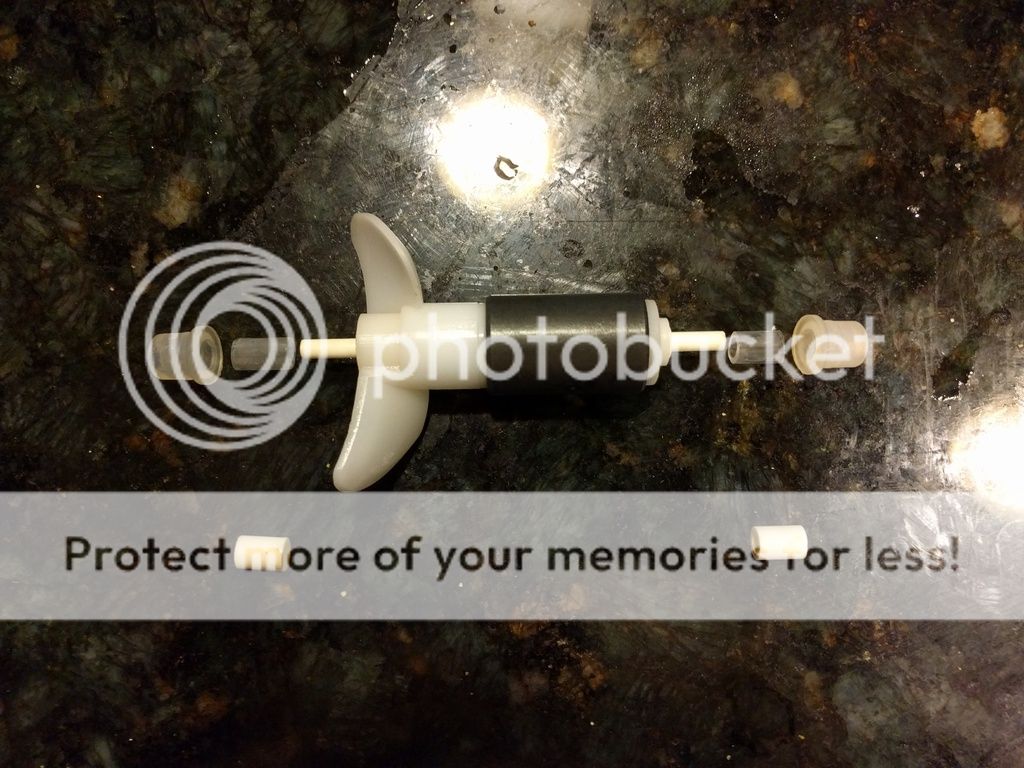

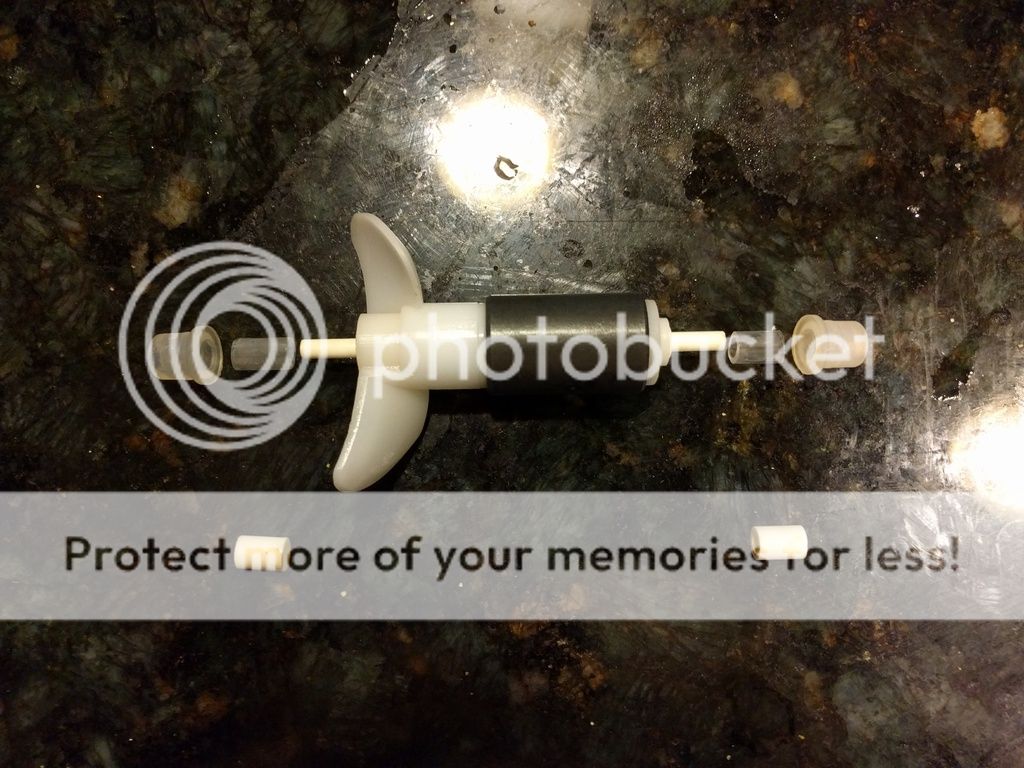

Top Reason Jebao wavemakers stop working and a super easy FIX for them!!!

I have been using Jebao WP and RW wavemaker pumps for a few years now and have had a few die on me (who hasn't). During my use with them I have determined the design of the impeller and where it connects to the outer casing and the inner motor mount points to be the BIGGEST FAILURE points bar none.

With that said, I figured I would share my easy and free solution to keep these pumps running longer (way longer as I haven't had a single failure since modding all of my pumps).

This little ceramic piece that slides over the Impeller = huge design flaw.

What happens is that this little cylinder WILL eventually sieze to the impeller shaft and the pump will seemingly be completely ruined and you'll throw it away"¦fear not, it's not ready for the trash just yet"¦

Picture of the little white ceramic cylinder can be seen here inside the clear rubber gasket:

Pop that nasty little white ceramic cylinder out of the clear housing and grab yourself a pair of scissors and some airline tubing"¦

Here is it cut to the length of the white cylinder piece we will be replacing"¦

Slide it over the shaft"¦.

Here it all is ready to be put together (white cylinders shown in pic but are ready for the trash)"¦

And, here it is fully assembled and ready to be put back into the motor where it WILL DEFINITELY run longer and without needing as much maintenance as before!

Enjoy!

-David

I have been using Jebao WP and RW wavemaker pumps for a few years now and have had a few die on me (who hasn't). During my use with them I have determined the design of the impeller and where it connects to the outer casing and the inner motor mount points to be the BIGGEST FAILURE points bar none.

With that said, I figured I would share my easy and free solution to keep these pumps running longer (way longer as I haven't had a single failure since modding all of my pumps).

This little ceramic piece that slides over the Impeller = huge design flaw.

What happens is that this little cylinder WILL eventually sieze to the impeller shaft and the pump will seemingly be completely ruined and you'll throw it away"¦fear not, it's not ready for the trash just yet"¦

Picture of the little white ceramic cylinder can be seen here inside the clear rubber gasket:

Pop that nasty little white ceramic cylinder out of the clear housing and grab yourself a pair of scissors and some airline tubing"¦

Here is it cut to the length of the white cylinder piece we will be replacing"¦

Slide it over the shaft"¦.

Here it all is ready to be put together (white cylinders shown in pic but are ready for the trash)"¦

And, here it is fully assembled and ready to be put back into the motor where it WILL DEFINITELY run longer and without needing as much maintenance as before!

Enjoy!

-David