Beefy_Reefy

New member

Has anyone made a dual 40 breeder stand? If so can you post pic?

Thanks

Thanks

Hey guys, been lurking around this forum for months now and finally decided to register. Im about to start building a stand for my 60"x18x26" 120g, woohoo! My question is: my floor is sloped about a 1/2" over the 5' span where im placing the tank. Should i be using 2x6 boards for my bottom horizontal frame with a center brace since most of the bottom frame will not be contacting the carpeted floor? I will shim but i just had a bad experience with a 120 cracking across the front pane and draining its contents all over my livingroom and i believe it was the stand possibly twisting but im not sure. Anyway i just wanted to hear opinions as to wether or not i needed a 2x6 lower frame, i will be using 2x6 for upper with a center brace mostly for door stops but the extra support is piece of mind. Thanks in advance.

My bro-in-law has some aluminum welded boxes that he made into aquariums by inserting glass. He could have used them for stands too. These things are decades old now, exposed over the years not just to regular aquarium water for his angelfish but also to saltwater in his French angel tanks. Oxidation is surface and not a problem.aluminum is nice but will oxidize, steel is too raw looking for me anyway. wood has so many endless options. 3 sides open shouldent be a problem. i think the stands we build are way over built, i know the ones i have built are. look at the ones that are press board that come with tanks, the elcheepo ones.

cross bracing is important i think more then the thickness of the wood being used, making it level on all 4 corners is also very important.

Why not slide the 125 in from one of the ends?I looking to build a stand for a Glass Marineland 300g tank thats

72" w x 36" d x 27 " h .. about 3500 lbs total when done.

Ideally I'd like the stand to be 36" high and have no center leg support

due to the 125 gallon sump I need to fit in there. Ideally I'd like the

stand a little larger then the tank.. 2" all the way around.

The returns are located in the rear two corners.

What do you guys think? What do I need to beef up?

3/4 plywood top?

Thanks, Mike

Why not slide the 125 in from one of the ends?

I've read some seemingly contradicting info in this thread.

It has been stated that since almost all lumber is bowed to some degree, the bow should be up.

It has also been stated that if there is any bowing, especially such that the corners of the tank do not touch the stand, the wood must be sanded / sawed flat.

Obviously there is an allowable limit to the amount of arch, but what is that limit over a 72" span for a glass tank?

BTW, my stand build hasn't started yet but will in the next few days, and will include space for a 65 fuge centered under the 180 main tank with vertical braces on each side of the 65. My greatest span will be about 40" so I'm assuming 2x4 top rails will be adequate. I'm thinking I'll buy 2x6s and run them through the table saw to even them out and cut them down.

I've read some seemingly contradicting info in this thread.

It has been stated that since almost all lumber is bowed to some degree, the bow should be up.

It has also been stated that if there is any bowing, especially such that the corners of the tank do not touch the stand, the wood must be sanded / sawed flat.

Obviously there is an allowable limit to the amount of arch, but what is that limit over a 72" span for a glass tank?

BTW, my stand build hasn't started yet but will in the next few days, and will include space for a 65 fuge centered under the 180 main tank with vertical braces on each side of the 65. My greatest span will be about 40" so I'm assuming 2x4 top rails will be adequate. I'm thinking I'll buy 2x6s and run them through the table saw to even them out and cut them down.

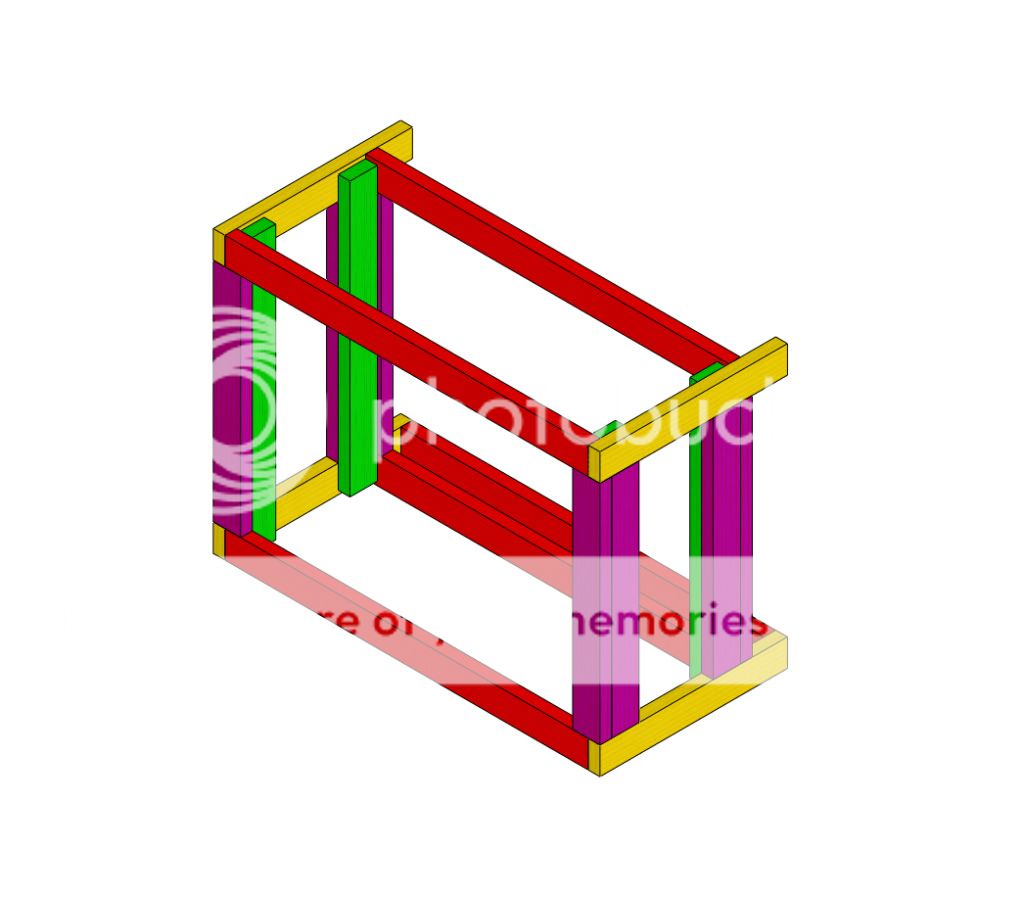

Same concept but pay attention to where the legs are located. They should be directly under the rails supporting the tank.

RocketEngineer