RocketEngineer

Space is big.

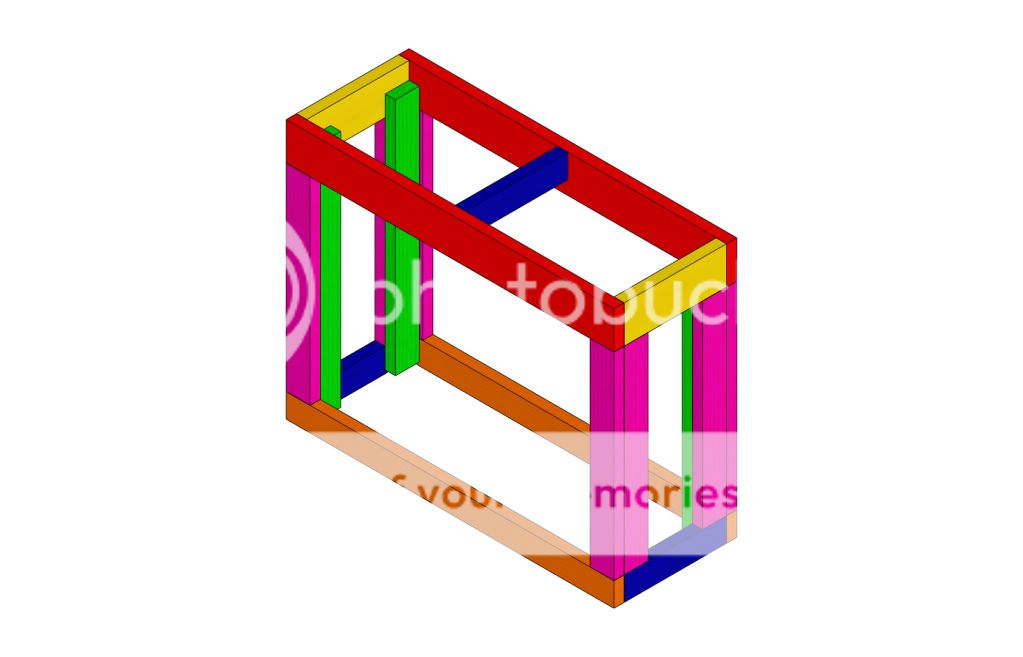

Quick question regarding exact dimensions... I've read through 30 or so pages and couldn't find the answer. I'm building a stand for a 120 gal RR. Most refer to the footprint as being 48" x 24". If you look at the specs from marineland, it's actually 48-3/8 x 24-3/8. Are you guys building the frames to exactly this dimension or adding an inch so the plastic frame centers on the 2x4?

So basically... What length and width should I use when planning the build out for a 120 RR?

I recommend adding that extra inch so the plastic sits near the center of the boards. Given that framing lumber has a rounded edge, this extra inch also ensures the tank sits on the flat part of the board, not on that rounded corner section.