You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Stands Template and Calculator

- Thread starter JohnL

- Start date

Floyd R Turbo

Either busy or sleeping

not sure what w/e means, but it's the end user they expect to pay this. If you want to rip your pics down, get the $2 chrome extension (for google chrome obviously) then you can download your entire album. You still have to do it a folder a folder at a time

Colin_Maybe

New member

anybody have a copy of the original post without the annoying speedometer? just want to check my design but can't that original post.

thanks!

I found an archived version using http://cachedview.com/

https://web.archive.org/web/20160308215838/http://reefcentral.com/forums/showthread.php?t=1169964

Hi All,

Can anyone recommend the correct wood for the following,

L=60 inch x W=36 inch x h=24

Was thinking of either 2x6 or 2x8?

Many thanks

If u don't mind a center brace then all 2 by 4 will be fine. If u don't want a center brace then u could use 2 by 4 on everything except the top brace. On the top brace it would be best to use a 2 by 8 but u would more then likely be fine with a double 2 by 6 to save some head room.

Something a lot of people don't think of when they size the top frame is how they are going to skin the front. If u have a 60" stand but u skin the front with plywood & only have a 48" opening for the door, then u can place a brace on each side of the door opening & u would only have a 48" span without a brace. In your case that would mean u could get by with a 2 by 6 top frame & u wouldn't have to worry about doubling the 2 by 6.

The issue with a 2 by 8 top frame is unless u build the stand 42" high (which would probably be to tall in your case with a 24" tank) it leaves very little headroom to get under the stand to work

cdfjr1975

New member

Do the screw strips need to be one piece per screw strip? I have scrap which would work but not go from top to bottom so thought to use one piece for the top and one for the bottom.

Also would pocket screws work for this join instead of screw strips? I know the intent was for simple joinery but wasn't sure if this was an option.

Sent from my Pixel XL using Tapatalk

Also would pocket screws work for this join instead of screw strips? I know the intent was for simple joinery but wasn't sure if this was an option.

Sent from my Pixel XL using Tapatalk

cdfjr1975

New member

Stand building 101, the corner should not stand like that.

Apparently one of the 2x4s are warped. Identified the culprit and now need to get another to replace or will the pressure of the tank level this out?

On a side note:

Don't take for granted that all 2x6s are created equal, even if they are from the same stack. One measures 5 1/8 while the other is 5 3/8

Guess if I need to pick up a flat 2x4 I will need to locate another 2x6 which matches one of these.

Sent from my Pixel XL using Tapatalk

Apparently one of the 2x4s are warped. Identified the culprit and now need to get another to replace or will the pressure of the tank level this out?

On a side note:

Don't take for granted that all 2x6s are created equal, even if they are from the same stack. One measures 5 1/8 while the other is 5 3/8

Guess if I need to pick up a flat 2x4 I will need to locate another 2x6 which matches one of these.

Sent from my Pixel XL using Tapatalk

I saw that. Thanks.

I'm looking for the formulas and such that went with the color coded stand.

Thank you!

was reading back thru from the beginning and found this.....

http://reefcentral.com/forums/showpost.php?p=11965020&postcount=219

johnfjenkins

New member

For a 220g 72x24wx30h, 2x8 for top rail should I add center support front and rear?

also should the purple be 2x6?

also should the purple be 2x6?

beth.thomas04

New member

Hey guys, im about to start setting up my first reef tank but im worried about the stand i got with the tank. Tank is 150 gallons.. 6 ft long and stand has no center brace.

Problem is i cant put a center brace in with the size of the sump..

Is there anything else i can do to ensure this will hold my tank or is it ok as is?

Sent from my SAMSUNG-SM-G930A using Tapatalk

Problem is i cant put a center brace in with the size of the sump..

Is there anything else i can do to ensure this will hold my tank or is it ok as is?

Sent from my SAMSUNG-SM-G930A using Tapatalk

Maybe someone will be interested to do somethig cleaner and wery solid (alu systems): https://www.youtube.com/watch?v=sg70S0GzReQ

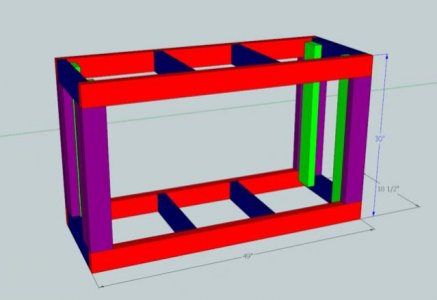

I have had freshwater (mulitiple aquariums) for years. However recently I came across a 90gal. I didn't like the stand so I decided to build one as per these plans. What do you guys think so far?

Attachments

Linkfalcon

New member

Hey guys looking for some help with plans for a custom stand for a propagation system

The stand will hold 4 10 gallon tanks side by side and a 40b sump I think does not need to be skinned or anything fancy

So the dementions of the stand will be

46x22x30 tall

Thanks guys for your time and help

The stand will hold 4 10 gallon tanks side by side and a 40b sump I think does not need to be skinned or anything fancy

So the dementions of the stand will be

46x22x30 tall

Thanks guys for your time and help

Last edited:

Grimreaperz

New member

Could we get someone to fix the pictures? In the OP post

BoisBlancBoy

New member

Here is the original picture.

I want to build a stand for a 48x24x24 120 gallon tank. So according to the original plan I would go with a 2x6 top from and the bottom frame would stay 2x4. I would like to get a 55 gallon sump in there 48x12.75x21”

How tall would you have the stand to make sure there was enough clearance for plumbing, skimmer maintenance etc? Do you think I’m using up too much space buy using the 55 gallon sump?

I want to build a stand for a 48x24x24 120 gallon tank. So according to the original plan I would go with a 2x6 top from and the bottom frame would stay 2x4. I would like to get a 55 gallon sump in there 48x12.75x21”

How tall would you have the stand to make sure there was enough clearance for plumbing, skimmer maintenance etc? Do you think I’m using up too much space buy using the 55 gallon sump?

Attachments

Last edited:

How much of a crown is too much? I've got everything built and 1/2" plywood on top and running a level across indicates I'm not perfectly flat. Is it worth just trying to get better lumber and rebuilding? Also was thinking of ditching the plywood if I have to sand it perfectly flat. this is for a 180 gallon tank.

Floyd R Turbo

Either busy or sleeping

Eliminating a crown is very important. For a tank over 48" long, you need full support all the way around. I had a crown on my 120 2x2x4 stand and didn't notice it, a few days after filling it I saw the seals forming bubbles and I had to tear it down & shim up the plywood on the corners.

So you have 2 options here, one is to remove the plywood and use a planer to shave the crown off of the 2x4s or 2x6s so that the plywood sits flat, or you can loosen up the screws enough to shim up the plywood and then screw it back down so it's secure and the screws are countersunk enough.

Depending on the crown, you might need very thin shims. I got a pack of cedar shakes from Menards, I think it was around $20-$30 for a pack (a large pack) and those are tapered down in varying thicknesses, some are paper thin. So you can snap them off in various widths and use 2 narrow shims inserted into the gap (one from inside, one from outside) and then you are essentially "extending" the 2x4s/2x6s such that the plywood will be level

So you have 2 options here, one is to remove the plywood and use a planer to shave the crown off of the 2x4s or 2x6s so that the plywood sits flat, or you can loosen up the screws enough to shim up the plywood and then screw it back down so it's secure and the screws are countersunk enough.

Depending on the crown, you might need very thin shims. I got a pack of cedar shakes from Menards, I think it was around $20-$30 for a pack (a large pack) and those are tapered down in varying thicknesses, some are paper thin. So you can snap them off in various widths and use 2 narrow shims inserted into the gap (one from inside, one from outside) and then you are essentially "extending" the 2x4s/2x6s such that the plywood will be level

Thanks for the help. The plywood top is glued down, so it's gonna get messy. I think I'll try to rebuild with some more true lumber. Then I'll ditch the plywood top anyways since once it's nice and flat I don't want to introduce any more opportunity for messing that up.

Has anyone thought of using LVL's? I know it will be .25" wider but those are nice and straight. obviously more expensive but stronger and less headache dealing with the crown.

Has anyone thought of using LVL's? I know it will be .25" wider but those are nice and straight. obviously more expensive but stronger and less headache dealing with the crown.

Floyd R Turbo

Either busy or sleeping

Yeah I was afraid of that...the gluing part.

Well, assuming this is a glass tank, you could potentially put another sheet of plywood down and shim between that one and the current top one, but you would somewhat lose the ability to shim from the other side, unless you cut out the middle of the current plywood, leaving only the part that is directly over a support. That wouldn't be difficult if you used a router and flush cutter riding on the supports. Could also use a jigsaw. Then you could get to the inside to shim.

Well, assuming this is a glass tank, you could potentially put another sheet of plywood down and shim between that one and the current top one, but you would somewhat lose the ability to shim from the other side, unless you cut out the middle of the current plywood, leaving only the part that is directly over a support. That wouldn't be difficult if you used a router and flush cutter riding on the supports. Could also use a jigsaw. Then you could get to the inside to shim.

Similar threads

- Replies

- 1

- Views

- 332

- Replies

- 0

- Views

- 108