First, let me say that I'm very grateful to RocketEngineer (and TheFishGuy, and others) for all the time and effort they've put into this thread, and I don't mean to critiize, but I found a significant error in the he's been using the deflection formula to determine what size beams are safe to use, and I thought I should say something.

I'll try to make this my last post on the topic of this deflection equation, except for posting a final corrected version of the Generic Stand Version of the Formula, to keep the thread focus from being too narrow.

Beam bending for a distributed load:

(5*P*L^4)/(384*Ixx*10^6) where P is weight per inch (P=W/L)

If P=W/L the foruma simplifies into the form I gave which is

(5*W*L^3)/(384*Ixx*10^6) where W is the weight of the tank.

Rocket,

The formula from you book is correct, but if W is the weight of the tank, you break the formula when you substiture W/L for P.

P and L already have precise meanings in the book formula, but W is a variable that you introduce, and if you define W as the tank weight, then it is not true that P=W/L. When you make that substitution, you are replacing P with a value that is at least two to four times greater than P, and so the value you get for deflection will be wrong (too large by the same factor).

The book formula is concerned only with forces acting along the length of a single beam, not a group of beams. The weight of the tank is always spread out over a group of two or more beams, so the formula doesn't care what the total weight of the tank is, it only cares about the amount of weight pushing down on the single beam with length = L.

The good news is that if you define W correctly, then it will be true that P=W/L, and the you will get correct deflection values from:

(5*W*L^3)/(384*Ixx*10^6)

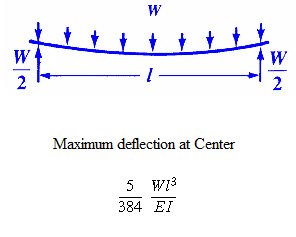

I found

the same formula, and a very useful drawing to go with it (see attachment). If you study the picture it becomes clear that W is the weight pushing down along the length L of a single beam. Since we don't balance our tanks on a single beam when we build tank stands, "the weight of the tank" will always be divided between two or more beams, so when using the formula on any single beam in a tank stand, W will always be less than the weight of the tank (usually about 1/2 to 1/4 of the tank weight)

Also notice, in the drawing, that L is the distance between the two support points. The beam actually extends a little beyond each of the support points. The beam is longer than L, so it isn't correct to use the length of the beam for L in the formula, we should use the distance between the support points. For a tank stand with 2x4's for legs, the support points are at the inside corner edges of the 2x4's. So when using the formula, we should not use the actual length of the beam for L, we should use the distance between the legs. It might not seem like a big deal, but L gets cubed, and so the error is magnified if L is off.

If you want to use this formula to decide what size your beams should be there are two ways to go:

1) If your stand design is generic enough and meets certain assumptions, you can just plug the beam height, and the tank's length, width, and height into the "Generic Stand" version of the equation that I'll post soon, and it will deduce the value of W and L, and calculate the beam deflection.

2) Or, you'll need to figure out what W should be for the beam you are interested in. I went into that at length in a previous post, but the short version is that you need to figure out how many pounds you'll have per linear inch of beam, and multiply that by L (the number of inches between the legs along the beam we are interested in) If P is the number of pounds per inch along your beam, then W=P*L (look familiar?).

Great, so how do you get P so that you can get W? In most cases we design our stands so that the beams are arranged symetrically around the center point of the tank bottom, in which case the tank weight will be evenly distributed along every inch of every beam, and P will be the same for every beam. Any arrangement of beams that is "balanced" around the center point of the tank bottom will work, for example:

a) One beam under each of the two long sides.

b) A beam under each of the four sides.

c) Either of the above, plus one or more beams equally spaced between two parallel beams.

Note: Cross members are not beams. For a beam to be a beam, it must be supported at each end by a leg (or part of a leg). If it is supported at each end by a beam instead of a leg, then it is a cross member, not a beam.

So for a stand with symetrically arranged beams, P (pounds per inch) will be the same for each beam, so it is legal to use values that span all beams to find P:

P = (tank weight) / (Sum of the lengths of all beams)

Notice that for any single beam, W=P*L, so W will be greater for a longer beams than for shorter one.

I think that TheFishGuy and RocketEngineer have been using the tank weight for W (maybe 1/2 the tank weight), and the full length of the beam for L, instead of the distance between the legs, i.e., they've been using values for W and L that are larger than what the formula expects. Since L gets cubed in the formula, and since W and L are in the numerator of the formula, I think the deflection values they've been using to decide what size lumber to use have been too high, maybe two to four (or more) times too high.

I don't consider the [beams along the] short sides [of the tank stand] because in my origianl post I mention that the outside 2X4 legs are option which means the ends of the top frame don't always have full support. It depends on how the legs are arranged whether the ends have support or not.

Okay, so if the "beams" along the short side don't have a leg at each end, they aren't really beams, they're cross members, and you are right to only count the two long beams. In such a case, when the stand only has two beams, you should set W = (tank weight)/2, but are you setting W that way for all beams, even if the stand has more than two beams?

A few things to keep in mind:

1) The 1/8" [0.125" - maximum safe distance of] deflection is a feel good number. I don't know what the professionals use but its what I feel should be about right.

Sure, understood, and since nobody has ever posted on this thread that their tank broke because you told them to use a beam that was too small, it's been safe to use. But what if, as I suspect, you've been plugging the wrong values into the formula for W and L, and getting deflection values that are double, tripple, or more what is accurate? If you fix your spreadsheet, and start getting accurate deflection numbers that are a lot lower than you've been using, is it still safe to use beams that the formula (when used correctly) says have a max deflection of .125"? The way I think you've been using the formula, a beam with a correct deflection estimate of 0.1" would have been rated by you as having a deflection of maybe 0.25", and would have been considered too weak. Should we now consider such a beam strong enough because it rates less than .125, or should we lower the cut off point to something like 0.05"? It's not fair of me to expect you to be able to answer that, but we need to pick a number and go with it. Any thoughts on what it should be? Maybe we can take some measurements from commercially sold stands, calculate the deflection they have, and use that as the limit?