Ok, I just got done scanning and reading all 4000+ posts of this monster thread, I wanted to avoid being one of those that asks the basic questions all over again!!

Just last night, I picked up my new 120 Gallon tank!!

I will be installing the coast-to-coast along the side of the tank (24" wide) as I may eventually convince the wife to let me make it a through-the-wall tank.

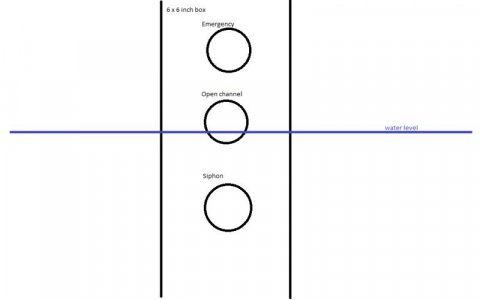

My goal is to design the filtration system so that a bare minimum of real estate is taken up in the display tank. I would like to do something similar to Robertifly's design which has a low-profile acrylic black interior box and a clear acrylic exterior box, connected by 4 bulkheads like this:

Robertifly your design is great, I hope you don't mind that I posted a few of those pics here!!

So in the interest of absolutely maximizing the interior space, I wanted to do a slight modificiation to this design and make the front panel angled upward like this:

(The external box is not the final design obviously, I just show the emergency standpipe for reference)

I figure that since the front panel has to be welded on after installation anyways (as it was in robertifly's design) that I might as well maximize the space in the tank and minimize the view of the internal box from the front (and back)

QUESTION #1: Does anyone see any issues with doing it this way?

The only thing I can think of is that it might be a little difficult to clean out the space at the bottom of the trough, but then again, the flow rate will be very high and nothing should be able to get trapped. The downside inherent to the design in general is that if you need to replace a bulkhead, you have to replace the inside box, as you have to break it apart to get the bulkhead out. The solution to this would be to reverse the bulkheads so that the nut is on the internal box, which is a possibility, and likely what I will do.

Also, I took an educated guess on the sequence of connection points as shown on the drawing, but maybe someone else can comment:

Bulkhead

Acrylic

Gasket #1

Tank Glass

Gasket #2

Acrylic

Compresson Nut

QUESTION #2: Should I add a gasket between the bulkhead and the internal box? (If I reversed the bulkhead, same question would apply)

QUESTION #3: Should I use a bead of silicone between the internal (and external??) acrylic box and the glass instead of a bulkhead? (I'm guessing this is a yes, since this would also eliminate dead space between the internal box and the glass, and a torque point on the external box from the weight of water and vibration of pipe during startup.)

I know that silicone won't bond acrylic and glass, but I do believe it would keep it sealed, especially when the bulkhead is keeping it under pressure.

If #2 and #3 are both "Yes" then it would be:

Bulkhead

Gasket

Acrylic

Silicone Bead

Glass

Silicone Bead

Acrylilc

Compression Nut

The final question I have it this:

QUESTION #4: If I make the internal and external boxes in a similar fashion out of glass and silicone everything in place, do I need to install a bulkhead? That is, if I drill a hole (or a series of holes) in a tank, is a bulkhead required in order to maintain the strength of the glass around each hole?

Maybe that's more of a hole-drilling / glass cutting type of question, but it's related to this design so I'm posting it here hoping someone will know the answer. I've seen designs on here with slots cut in the glass and back edges shaved off to create a weir, and comments about bracing and such. It would save a lot of internal box space if I could drill 4 holes with the diameter of the interior cross-section of a 1.5" bulkhead versus 4 hoels for 1.5" bulkhead, and additional space taken up by the bulkhead. I haven't seen anyone do this, either that or I missed it and I wonder if there is a reason.

Thanks for reading my long post and I hope I can get these questions answered...