stormrider27

Member

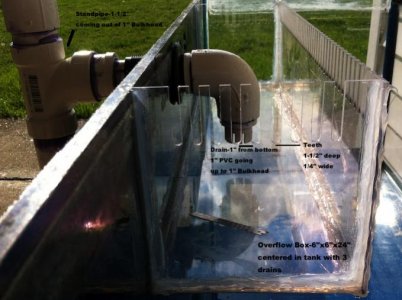

On an external does it matter how the holes spaced on the horizontal plane? I am think of three holes spaced out equally across the back with my external box almost running the entire length of the tank but since I hope to start cutting tomorrow I thought I would check in case first.

Thanks!

Thanks!

Last edited: