GROSSR

Active member

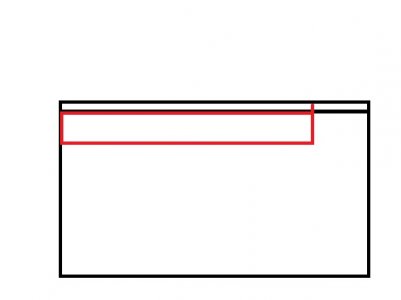

Without a picture, I don't fully understand your displays trim.

However, you can put the overflow anywhere you want. You can put it above the trim, but that is less room for error. I personally am never comfortable with the water level above the trim.

My C2c is sealed against one side of the tank and is 6" inches short of the other side. I have a 1/3" gap beneath the bottom of the trim and top of the C2C. I heard no noise from the water flowing over the C2C.

wherever you put the C2C water is going to overflow the top of it.

Water seeks the point of least resistance.

However, you can put the overflow anywhere you want. You can put it above the trim, but that is less room for error. I personally am never comfortable with the water level above the trim.

My C2c is sealed against one side of the tank and is 6" inches short of the other side. I have a 1/3" gap beneath the bottom of the trim and top of the C2C. I heard no noise from the water flowing over the C2C.

wherever you put the C2C water is going to overflow the top of it.

Water seeks the point of least resistance.