uncleof6

Active member

Cheers for the reply uncleof6,

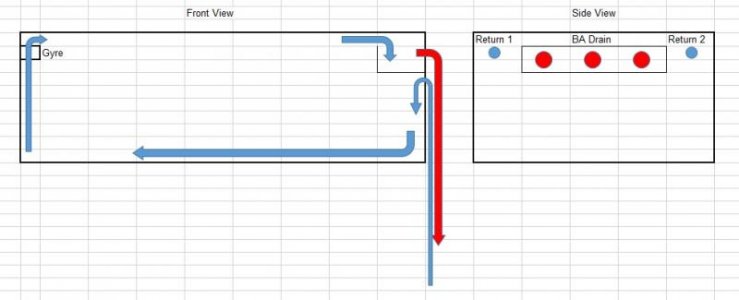

Yup, I thought that might be the case. I was just trying to capture the waste/drain from the display straight to the skimmers so they get a straight shot at the dirty water.

Not much difference but the less pumps running the lower the cost of equipment, lecky, noise and things to go wrong.

I'm not sure I agree with the filter socks though. I've run a large system before and there is always some larger particles that a sock would be best at removing. You do have to keep on top of maintance as you don't want waste staying in the system. But it's either a case of siphoning them up or catching them in a sock.

Or, keep the flow rate high enough that particulates are kept in suspension, where they are utilized as a food source for your critters. I could feed you a bunch of anecdote about the 250 or so systems I have running without any form of mechanical filtration, and how much of a mess I would be in with clients, that have way more money than I, if the systems were loading up with crud. I would much rather say that on the whole, maintenance is neglected with socks, and skimmers as well. It is a tiresome chore to change the socks every day, and clean the skimmer every week. We all would like to reduce the husbandry end of the hobby, but unfortunately, there is no way around it.