You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silent and Failsafe Overflow System

- Thread starter JohnL

- Start date

sleepydoc

Team RC

The 'standard' position is about ¼-½" ABOVE the emergency drain. Having it positioned like this lets the water rise to the level of the emergency drain and stay there during start up without 'tripping' the open channel drain over to a full siphon. If the open channel flips over to a full siphon and rapidly drains the overflow box. If this happens before the siphon channel has had a chance to purge the air and stabilize, it will just suck in air and never reach a steady state.

I would secure the line either with a zip tie or by some other means

I would secure the line either with a zip tie or by some other means

mmn

New member

Heh I had no idea. Thanks man. I'll position it a little higher then.

The open channel should only go to full siphon if the dry emergency is clogged. It is the last failsafe.

Outdrsyguy1

New member

anyone have any links to flow rates of different sized pipe under full suction?

Hi all, was hoping for some advice. I'm setting up a 900 gallon system and would like to go the bean animal route. I'm trying to size the overflow box and figure out how many bulk heads are needed.

Tank is 10' x 56" x 33" and my overflow will be an external box (current design is 60" long overflow). I was going to use a reeflo hammerhead for the sump ~5,000 gph) and current plan is a closed loop with eductors for flow (another 5,000 gph into the sump). I"m still researching the eductors but when sized properly, it looks like I could get ~25,000 gph water movement out of them.

Anyways, anyone able to make suggestions on what size pipe under full suction can handle 10,000 gph? I assume even though the tanks a monster, i would still want to go with the 3 pipe bean animal design?

oh, sump will be about 3' underneath overflow

Thanks!

tidus10

New member

The open channel should only go to full siphon if the dry emergency is clogged. It is the last failsafe.

and i was thinking it was

Full siphon fails somehow,

secondary goes full siphon and if that fails..

open channel turns into a straigh drain and rescues it all..

Thanks for all the help!

sleepydoc

Team RC

anyone have any links to flow rates of different sized pipe under full suction?

I haven't seen much good data on this. This post has some calculated rates.

http://www.reefcentral.com/forums/showthread.php?t=1814606

Floyd R Turbo

Either busy or sleeping

805reef

New member

I am going to use a straight down pipe for my display tank but I have a smaller tank that will be under the stand next to the sump that will be used for chaeto and for new fish acclimation.

Do to the limited space under the stand and the sizes of the smaller tank and sump I may need to use a short horizontal run. Would this work? The horizontal part is about 20" long. Is that too much to be able to get the siphon going?

Do to the limited space under the stand and the sizes of the smaller tank and sump I may need to use a short horizontal run. Would this work? The horizontal part is about 20" long. Is that too much to be able to get the siphon going?

sleepydoc

Team RC

20" isn't really that short - I don't have experience with setups like this, but I wouldn't be surprised if it caused problems.

You could try it and see how it works. If there is absolutely no way to avoid the horizontal run and it does cause isssues, one option might be to add a means to vent the air - perhaps a tee with a john guest valve or something similar. You could also have an upside down P trap taht would collect the bubbles and use the drain plug on it to rig some sort of vent. You would have to vent it manually, so it wouldn't be automatically starting, but it might work.

Edit- potential problemm with the solution I suggested is that it could entrain air rather than vent it. If it's down far enough, I thing the pressure gradients would be such that it would vent air, bit I can't be positive.

You could try it and see how it works. If there is absolutely no way to avoid the horizontal run and it does cause isssues, one option might be to add a means to vent the air - perhaps a tee with a john guest valve or something similar. You could also have an upside down P trap taht would collect the bubbles and use the drain plug on it to rig some sort of vent. You would have to vent it manually, so it wouldn't be automatically starting, but it might work.

Edit- potential problemm with the solution I suggested is that it could entrain air rather than vent it. If it's down far enough, I thing the pressure gradients would be such that it would vent air, bit I can't be positive.

805reef

New member

20" isn't really that short - I don't have experience with setups like this, but I wouldn't be surprised if it caused problems.

You could try it and see how it works. If there is absolutely no way to avoid the horizontal run and it does cause isssues, one option might be to add a means to vent the air - perhaps a tee with a john guest valve or something similar. You could also have an upside down P trap taht would collect the bubbles and use the drain plug on it to rig some sort of vent. You would have to vent it manually, so it wouldn't be automatically starting, but it might work.

Edit- potential problemm with the solution I suggested is that it could entrain air rather than vent it. If it's down far enough, I thing the pressure gradients would be such that it would vent air, bit I can't be positive.

Thanks for the response. I'll try out some other things...

Might help to make it less horizontal with 45 degree els if you have enough vertical space.

I have some 45's on the right side, but I have the left tank up as high as it can go... I wish there were like 10 or 15 degree elbows...

How about this, does this change anything putting the tee more to the right? Or is it still all the same?

mmn

New member

The tee is only there for a clean-out except on the open channel where it also provides a way to connect the airline for converting the open channel to a full siphon in an emergency. Since you have a union there you don't really need that tee. That might buy you enough room to go from the tank to the sump on a 45 degree angle.

On another note - I can't see the three pics in your OP, so I can't see what you're doing about the other two BA drains. I also don't see any valve on the one you are showing so that looks like it's just the dry emergency?

On another note - I can't see the three pics in your OP, so I can't see what you're doing about the other two BA drains. I also don't see any valve on the one you are showing so that looks like it's just the dry emergency?

805reef

New member

The tee is only there for a clean-out except on the open channel where it also provides a way to connect the airline for converting the open channel to a full siphon in an emergency. Since you have a union there you don't really need that tee. That might buy you enough room to go from the tank to the sump on a 45 degree angle.

On another note - I can't see the three pics in your OP, so I can't see what you're doing about the other two BA drains. I also don't see any valve on the one you are showing so that looks like it's just the dry emergency?

hmmm... not sure what happened to the first pics but here they are again.

all of the pics are just quick mock ups so that I could ask you guys what you thought. I will not be using a union on the final. All 3 drains will follow the same path and the full siphon will have a gate valve and the open channel will have the airline.

Maybe another dumb question... would having two 10" horizontal runs seperated by zigzag 45's be the same as having one 20" horizontal?

Ok, you guys got my brain going and I think I found a solution. Using 2 back to back 45's I can make it have a slight downward angle the whole run without any horizontals. Again the union is only there because I was too lazy to look for a coupler for this mock up. The final will not have a coupler or union there

Last edited:

sleepydoc

Team RC

I'd try something like the last pics where you have it angled. I don't think 2 short horizontal runs would be appreciably better than 1 long run.

One idea/suggestion for creating a non-standard angle - you can bend PVC pipe by heating up with a heat gun, or in an oven. That would avoid the mishmash of 45º's

One idea/suggestion for creating a non-standard angle - you can bend PVC pipe by heating up with a heat gun, or in an oven. That would avoid the mishmash of 45º's

StrangeDejavu

Member

Hi all,

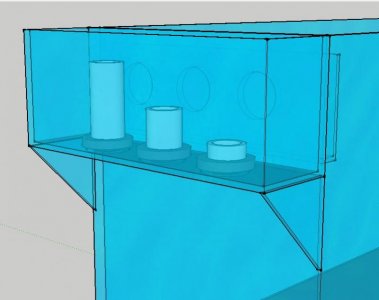

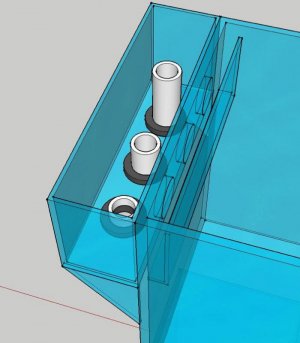

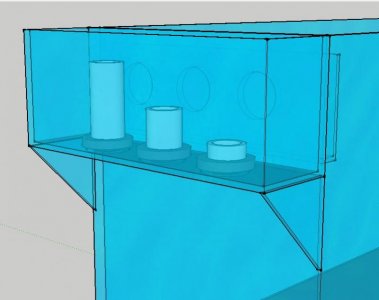

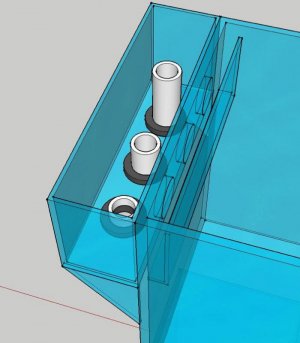

Looking to do a Bean overflow on my 40b with 20l sump. Ideally, I want an external box with minimal intrusion inside the tank, similar to this. This is my first salt tank and i've never drilled before, so I don't even know where to begin as far as plans and dimensions go. Anyone ever done this same setup but with 1" PVC instead of 1.5"? If so, I would greatly appreciate pics on where you drilled, how far down, the spacing, etc.

Thanks!

Looking to do a Bean overflow on my 40b with 20l sump. Ideally, I want an external box with minimal intrusion inside the tank, similar to this. This is my first salt tank and i've never drilled before, so I don't even know where to begin as far as plans and dimensions go. Anyone ever done this same setup but with 1" PVC instead of 1.5"? If so, I would greatly appreciate pics on where you drilled, how far down, the spacing, etc.

Thanks!

xaflatoonx

New member

Man - i came to ask exactly the same question.

had a quick discussion with sleepydoc and tidus as well on a separate thread.

I am getting a 6ft tank... 125-150G.

And i was originally planning on getting a 24" reefsavy ghost overflow.

But then in the past 48 hours reading hundreds of posts on this thread by Bean Animal and Uncleof6 - It seems like that would be a BAD BAD idea.

And i need to put a C2C or atleast an elongated overflow box INSIDE the tank

From which the 3 pipes will run directly.

So just like StrangeDejavu - I am trying to see if there is a way to put the overflow box OUTSIDE the tank and have a way of getting the water flow into it. Could the holes I drill into the back of tank just work as a drain into that overflow box outside?

The biggest charm of that 24" ghost overflow from reefsavy - was the clean look of the tank... and having a overflow box inside the tank with pipes sticking out just doesnt look all that great.

I fully understand the function over form discussion - just looking to see if there any options is all.

Thanks again. This thread was crazy informative.

had a quick discussion with sleepydoc and tidus as well on a separate thread.

I am getting a 6ft tank... 125-150G.

And i was originally planning on getting a 24" reefsavy ghost overflow.

But then in the past 48 hours reading hundreds of posts on this thread by Bean Animal and Uncleof6 - It seems like that would be a BAD BAD idea.

And i need to put a C2C or atleast an elongated overflow box INSIDE the tank

From which the 3 pipes will run directly.

So just like StrangeDejavu - I am trying to see if there is a way to put the overflow box OUTSIDE the tank and have a way of getting the water flow into it. Could the holes I drill into the back of tank just work as a drain into that overflow box outside?

The biggest charm of that 24" ghost overflow from reefsavy - was the clean look of the tank... and having a overflow box inside the tank with pipes sticking out just doesnt look all that great.

I fully understand the function over form discussion - just looking to see if there any options is all.

Thanks again. This thread was crazy informative.

tidus10

New member

Yes man you can just drill holes that go into an external overflow, I've seen a few. You can silicone a glass box on the outside of your tank. That you can run your plumbing into. Here are some rough pics I found.

It's possible and like I mentioned I bought the synergy ghost overflow and I really like it. I was just giving other solutions for you. [emoji2]

It's possible and like I mentioned I bought the synergy ghost overflow and I really like it. I was just giving other solutions for you. [emoji2]

tidus10

New member

Hi all,

Looking to do a Bean overflow on my 40b with 20l sump. Ideally, I want an external box with minimal intrusion inside the tank, similar to this. This is my first salt tank and i've never drilled before, so I don't even know where to begin as far as plans and dimensions go. Anyone ever done this same setup but with 1" PVC instead of 1.5"? If so, I would greatly appreciate pics on where you drilled, how far down, the spacing, etc.

Thanks!

Even 1" will be A LOT for the 40, you can honestly get away with 3/4" but it's all the same just different sizes. I've heard that when drilling glass its best to give 1 - 1.5 the width of your hole gap between holes. So what I mean is, if you have a 1" hole you're drilling, leave at least 1" to 1.5" gap before you drill the next hole.

With a rimmed tank, remember you want to be able to get your hand into the inside weir box Incase something happens. So I'd say at the bottom of the back trim would be ideal. Just so when you fill it with water you cannot see a gap between the black trim and water.

xaflatoonx

New member

Thanks Tidus -

You already shared some pics that i really appreciate - do you have the synergy installed already? could i get some pics of it working ? pretty please.

The surface skimming is good?

You already shared some pics that i really appreciate - do you have the synergy installed already? could i get some pics of it working ? pretty please.

The surface skimming is good?

Similar threads

- Replies

- 3

- Views

- 166

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 780