I read the entire first 40 page portion of this thread, then started reading this 300 page portion, but I don't think I'll make it through all 8000+ posts in my lifetime. So I searched this thread, and all of RC, for similar situations to mine, found a few, but none that specifically answers my question ... so here I am.

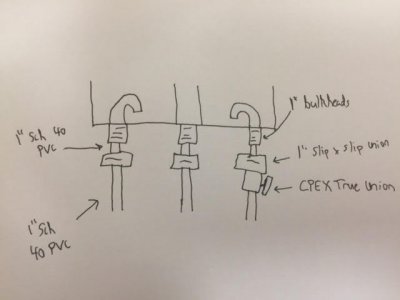

I am planning a 220g tank with a bean overflow and a 180g sump in the basement. I have about 11' of vertical drop, and about 14' of horizontal (which can be sloped in the basement). I am trying to design for flow through the sump at about 1200-1400gph.

I understand the issues with horizontal runs and the siphon channel. I used the calculator on bean's page to find that 1" pipe and my vertical drop will give me a theoretical siphon of almost 4000gph, and 1.25" pipe bumps that to about 6000gph.

Now, my questions:

1. Given that 1" will flow at least 2x what I need, is it better to use this smaller pipe for the siphon vs. 1.25"? Is there a potential benefit to the smaller pipe because it will help overcome the issues related to my horizontal runs (less air in the smaller pipe means easier to start siphon?).

2. With a siphon that is 2x the desired flow, any idea how much tuning is available via the gate valve? Might I find that I need to run the gate almost wide open? That would push me to run the larger pipe, but then am I losing the potential benefit of the easier to start siphon? How much wiggle room do I need to leave myself?

3. Does anyone have practical experience with around 11' vertical drop and 14' horizontal - what size pipe did you use for your siphon, are you happy with what you have?

Thanks for reading ...

Tom