You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silent and Failsafe Overflow System

- Thread starter JohnL

- Start date

zachtos

Active member

Has anyone used a carlson surge device with this overflow?

How would I calibrate it if so (planning a 40-50G surge maybe)?

I am planning a 300 deep dimension from marineland and I think I am limited on the hole sizes they give. Can drill more holes of course, or make all four holes used for drains (maybe 2 holes are stand pipes, 1 emergency, 1 siphon?)

How would I calibrate it if so (planning a 40-50G surge maybe)?

I am planning a 300 deep dimension from marineland and I think I am limited on the hole sizes they give. Can drill more holes of course, or make all four holes used for drains (maybe 2 holes are stand pipes, 1 emergency, 1 siphon?)

Has anyone used a carlson surge device with this overflow?

How would I calibrate it if so (planning a 40-50G surge maybe)?

I am planning a 300 deep dimension from marineland and I think I am limited on the hole sizes they give. Can drill more holes of course, or make all four holes used for drains (maybe 2 holes are stand pipes, 1 emergency, 1 siphon?)

This is a question I have been looking for the answer to as well. Any advice on the Carlson system combined with BEAN overflow?

Also another question I believe nobody has asked yet; Would it be possible to have several BEAN systems each in its own separate overflow box in the same tank? What criteria would this dictate for the design/setup?

Has anyone used a carlson surge device with this overflow?

How would I calibrate it if so (planning a 40-50G surge maybe)?

I am planning a 300 deep dimension from marineland and I think I am limited on the hole sizes they give. Can drill more holes of course, or make all four holes used for drains (maybe 2 holes are stand pipes, 1 emergency, 1 siphon?)

This is a question I have been looking for the answer to as well. Any advice on the Carlson system combined with BEAN overflow?

Also another question I believe nobody has asked yet; Would it be possible to have several BEAN systems each in its separate overflow box in the same tank? What criteria would this dictate for the design/setup?

jason2459

Well-known member

No questions here just updating how I'm setup. As I haven't touched it sincing updating this thread my setup in 2010 I think it was?

I was setup with 3 1" runs with around 12 foot horizontal run to a utility closet I had my sump setup in. I have moved it out of there setting up a new space for it moving my sump closer under the tank and at least doubled my flow from ~750gph to ~1400gph.

So, I took advantage of this switch to also upgrade the lines to 1.5" to just make sure the flow would be 0 issues and if I ever wanted to go with even more flow.

Luckily, when I setup the 180 I left room behind to work albeit not very comfortably but enough. Also, had enough foresight to start off with 1.5" and stepped down to 1"

Just enough room to get a hacksaw back there. Removing the 1" lines.

And new 1.5" lines starting with some ultraflex

And finished off with some hard plumbing underneath

Also, upgraded the return line to 1.5" too

Working like a champ. Full siphon can't really see under the water up top. Middle emergency. Bottom open channel.

Thak you again and again BeanAnimal!

I was setup with 3 1" runs with around 12 foot horizontal run to a utility closet I had my sump setup in. I have moved it out of there setting up a new space for it moving my sump closer under the tank and at least doubled my flow from ~750gph to ~1400gph.

So, I took advantage of this switch to also upgrade the lines to 1.5" to just make sure the flow would be 0 issues and if I ever wanted to go with even more flow.

Luckily, when I setup the 180 I left room behind to work albeit not very comfortably but enough. Also, had enough foresight to start off with 1.5" and stepped down to 1"

Just enough room to get a hacksaw back there. Removing the 1" lines.

And new 1.5" lines starting with some ultraflex

And finished off with some hard plumbing underneath

Also, upgraded the return line to 1.5" too

Working like a champ. Full siphon can't really see under the water up top. Middle emergency. Bottom open channel.

Thak you again and again BeanAnimal!

Floyd R Turbo

Either busy or sleeping

What's with the mass of silicone around the bulkhead there?

jason2459

Well-known member

What's with the mass of silicone around the bulkhead there?

Isn't that how you're supposed to install bulkheads? :jester:

That was a patch job to silicone glass to the glass that was broken while moving the tank into the house. It hit the corner of a wall as we were making a curve. I was quite ticked off and I went over zealous on the silicone and didn't care one bit how it looked as no one ever sees it. I basically recovered the right half of the overflow with new glass and drilled a new hole through the new glass on the bottom.

Last edited:

iv had my tank set up since October last year and its really bugging me with the water going down the pipes noise.

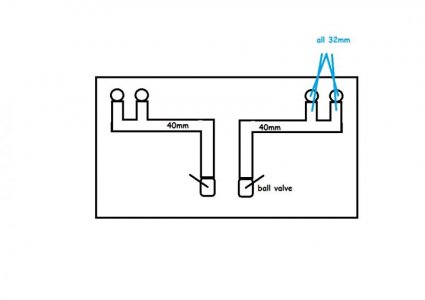

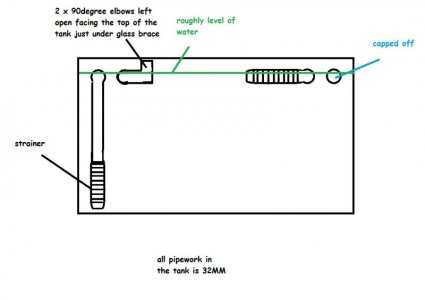

so iv been thinking about using the bean animal overflow and doing a coast to coats weir as iv got 4 holes drilled already. so my question is could i use 3 of the holes for the bean animal and use 1 for my return pipework and would it matter that 2 holes are together and 1 will be at the other end of the tank?

the pictures are from when i first got the tank (it was second hand) the drawing shows how the plumbing is as of now.

REAR VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353364&stc=1&d=1467222880

FRONT VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353365&stc=1&d=1467222885

some pictures of the tank when i was working on it in the garage back in october.....the tank is currently stocked

http://www.reefcentral.com/forums/attachment.php?attachmentid=353367&stc=1&d=1467222911

http://www.reefcentral.com/forums/attachment.php?attachmentid=353366&stc=1&d=1467222899

so iv been thinking about using the bean animal overflow and doing a coast to coats weir as iv got 4 holes drilled already. so my question is could i use 3 of the holes for the bean animal and use 1 for my return pipework and would it matter that 2 holes are together and 1 will be at the other end of the tank?

the pictures are from when i first got the tank (it was second hand) the drawing shows how the plumbing is as of now.

REAR VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353364&stc=1&d=1467222880

FRONT VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353365&stc=1&d=1467222885

some pictures of the tank when i was working on it in the garage back in october.....the tank is currently stocked

http://www.reefcentral.com/forums/attachment.php?attachmentid=353367&stc=1&d=1467222911

http://www.reefcentral.com/forums/attachment.php?attachmentid=353366&stc=1&d=1467222899

Attachments

zachtos

Active member

I have a 300G marineland DD tank I am setting up. It has TWO corner overflows, each with 1" bulk heads. How do I rig this up if they are in opposite corners like that?

Also, what will be maximum flow I can achieve?

I have a reeflo Barracuda (I think it's 6000gph at no head, 4000 or so at 5 feet).

If too much flow, can I use one of the other 1" pipes to do double full siphon, emergency pipe and a drain pipe? Then use over the top pipe for return flow?

Also, what will be maximum flow I can achieve?

I have a reeflo Barracuda (I think it's 6000gph at no head, 4000 or so at 5 feet).

If too much flow, can I use one of the other 1" pipes to do double full siphon, emergency pipe and a drain pipe? Then use over the top pipe for return flow?

EvMiBo

VictoriaConcordiaCrescit

iv had my tank set up since October last year and its really bugging me with the water going down the pipes noise.

so iv been thinking about using the bean animal overflow and doing a coast to coats weir as iv got 4 holes drilled already. so my question is could i use 3 of the holes for the bean animal and use 1 for my return pipework and would it matter that 2 holes are together and 1 will be at the other end of the tank?

the pictures are from when i first got the tank (it was second hand) the drawing shows how the plumbing is as of now.

REAR VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353364&stc=1&d=1467222880

FRONT VIEW

http://www.reefcentral.com/forums/attachment.php?attachmentid=353365&stc=1&d=1467222885

some pictures of the tank when i was working on it in the garage back in october.....the tank is currently stocked

http://www.reefcentral.com/forums/attachment.php?attachmentid=353367&stc=1&d=1467222911

http://www.reefcentral.com/forums/attachment.php?attachmentid=353366&stc=1&d=1467222899

This would work fine.

I would also consider drilling one more return hole for five holes total. I had to do something similar with a small side on my peninsula. 1/4" glass is very easy to drill (what I used for the overflow weir/box)

This is my diy bean animal. [photo taken from the other small end]

Attachments

Last edited:

zachtos

Active member

How do I rig up this 300G marineland DD tank I am setting up?

It has TWO corner overflows, each with 1" bulk heads.

Also, what will be maximum flow I can achieve?

If too much flow from return, then I can go over the top of tank for return flow.

Last edited by a moderator:

jduck

Member

Depends on how long the down tube is after the bulkhead. No siphon 1" bulkhead will do 600/650gph.

How do I rig up this 300G marineland DD tank I am setting up?

It has TWO corner overflows, each with 1" bulk heads.

Also, what will be maximum flow I can achieve?

If too much flow from return, then I can go over the top of tank for return flow.

Last edited by a moderator:

zachtos

Active member

Depends on how long the down tube is after the bulkhead. No siphon 1" bulkhead will do 600/650gph.

These are setup for 1" standard bulk heads, so I could have a total of 4.

It is 5 feet from top of tank to floor, and 3 feet from bottom of tank/hole to the floor, sump will be on flat floor under the tank.

Ideally I could run 1 or 2 full siphon, an emergency tube and a standpipe. I think it sounds like the emergency pipe will be too small at 1" to be of use... maybe I can use leaky uniseals to go higher diamater pipe.

sleepydoc

Team RC

How do I rig up this 300G marineland DD tank I am setting up?

It has TWO corner overflows, each with 1" bulk heads.

Also, what will be maximum flow I can achieve?

If too much flow from return, then I can go over the top of tank for return flow.

Depends on how long the down tube is after the bulkhead. No siphon 1" bulkhead will do 600/650gph.

A 1" pipe will run in excess of 1000 GPH at full siphon, depending on the drop.

The bigger problem is using this setup for a bean overflow. You need 3 pipes plus a return for the bean overflow and to function properly, they need to be in the same body of water. (When water flows over a weir the water in the overflow is separate from that in the tank for our purposes, making 2 bodies of water. In a dual corner flow setup there are 3 bodies of water until the levels in the overflows rise up above the overflow.) There are 3 ways of doing a bean with this setup that I know of:

1. Have the siphon and the open channel in one corner and the return and dry emergency in the other. This will only work if the dry emergency is above the level of the overflows. It limits the overflow area to one corner, far from ideal in a large tank, and creates a stagnant area in the second overflow that has the emergency and the return.

2. Modify the overflows to connect them together- I have seen people cut a notch in the overflows and put a weir between them. This gives improved surface skimming from the longer overflow area and lets you use the existing bulkhead holes but is quite a bit of work and difficult to make look good.

3. Remove the corner flows and replace with a coast to coast internal or external overflow. Realistically, this is the best solution but also involves modifying the tank and potentially drilling holes .

Last edited by a moderator:

zachtos

Active member

A 1" pipe will run in excess of 1000 GPH at full siphon, depending on the drop.

The bigger problem is using this setup for a bean overflow. You need 3 pipes plus a return for the bean overflow and to function properly, they need to be in the same body of water. (When water flows over a weir the water in the overflow is separate from that in the tank for our purposes, making 2 bodies of water. In a dual corner flow setup there are 3 bodies of water until the levels in the overflows rise up above the overflow.) There are 3 ways of doing a bean with this setup that I know of:

1. Have the siphon and the open channel in one corner and the return and dry emergency in the other. This will only work if the dry emergency is above the level of the overflows. It limits the overflow area to one corner, far from ideal in a large tank, and creates a stagnant area in the second overflow that has the emergency and the return.

-I could make the return point 5% flow into the stagnant chamber and remainder into tank. The emergency is only 1" pipe, not sure if that is enough or maybe make both as emergency pipes? How much flow could I get from the 1" siphon and 1" standpipe in that case? (5' from top to floor, or 4' worst case)

2. Modify the overflows to connect them together- I have seen people cut a notch in the overflows and put a weir between them. This gives improved surface skimming from the longer overflow area and lets you use the existing bulkhead holes but is quite a bit of work and difficult to make look good.

-I am planning a great stuff black foam background w/ rock pieces ziptied to egg crate, so this is possible. It would not really be noticeable I think, and I do have 36" depth to work with.

3. Remove the corner flows and replace with a coast to coast internal or external overflow. Realistically, this is the best solution but also involves modifying the tank and potentially drilling holes .

-I am not sure if the marineland 300G DD is able to be drilled on bottom pane or not... If I can safely drill the bottom I can do it, I've drilled small tanks before.

Comments above, but I think if someone can verify that my tank is safe to drill the bottom pane (marineland 300G DD), then it would be easiest to add larger holes and extend an overflow box. If I did so, I have two 1" bulkheads now, how many more drilled holes of what size would be best (assuming I want maybe 1500-2500 gph max?

I can't help on if a 300 dd is tempered or not, but on a bean animal the siphon will take most of the flow. With option #1 or option #2 u will be somewhat limited with the 1" bulkheads for drains. I believe u will be maxing out at about 1,200 to maybe 1,500 gph with the 1" drains.

If u go with option #3 u can cap your existing bulkheads or use a couple for your returns & drill out of the back of the tank for 1.5" bulkheads for drains. A 1.5" siphon can handle 2,500 to 3,000 gph (My flow rates aren't exact but they should be close). This way you wouldn't lose the 5" or so from the back of the tank.

If u don't want to come out the back u can still come out the bottom, your c2c overflow would just have to go all the way to the bottom. U may be able to incorporate your foam wall to act as the overflow box. If u go this route I would use two of your existing 1" bulkheads for your returns & drill 3 holes for 1.5" bulkheads for the drains. This way u will be able to handle twice the flow & not be limited by the 1" syphon.

Whatever route u choose to go make sure your 3 drains are the same size or your siphon is the smaller drain. U don't want your syphon to be bigger then your emergency drains.

If u go with option #3 u can cap your existing bulkheads or use a couple for your returns & drill out of the back of the tank for 1.5" bulkheads for drains. A 1.5" siphon can handle 2,500 to 3,000 gph (My flow rates aren't exact but they should be close). This way you wouldn't lose the 5" or so from the back of the tank.

If u don't want to come out the back u can still come out the bottom, your c2c overflow would just have to go all the way to the bottom. U may be able to incorporate your foam wall to act as the overflow box. If u go this route I would use two of your existing 1" bulkheads for your returns & drill 3 holes for 1.5" bulkheads for the drains. This way u will be able to handle twice the flow & not be limited by the 1" syphon.

Whatever route u choose to go make sure your 3 drains are the same size or your siphon is the smaller drain. U don't want your syphon to be bigger then your emergency drains.

zachtos

Active member

I can't help on if a 300 dd is tempered or not, but on a bean animal the siphon will take most of the flow. With option #1 or option #2 u will be somewhat limited with the 1" bulkheads for drains. I believe u will be maxing out at about 1,200 to maybe 1,500 gph with the 1" drains.

If u go with option #3 u can cap your existing bulkheads or use a couple for your returns & drill out of the back of the tank for 1.5" bulkheads for drains. A 1.5" siphon can handle 2,500 to 3,000 gph (My flow rates aren't exact but they should be close). This way you wouldn't lose the 5" or so from the back of the tank.

If u don't want to come out the back u can still come out the bottom, your c2c overflow would just have to go all the way to the bottom. U may be able to incorporate your foam wall to act as the overflow box. If u go this route I would use two of your existing 1" bulkheads for your returns & drill 3 holes for 1.5" bulkheads for the drains. This way u will be able to handle twice the flow & not be limited by the 1" syphon.

Whatever route u choose to go make sure your 3 drains are the same size or your siphon is the smaller drain. U don't want your syphon to be bigger then your emergency drains.

I might drill, but leaning toward not hurting the warranty at this point, if there even is one. Maybe just go low flow of 1000-1500gph on return and divert the rest with dual DCS-9000 motors to an algal turf scrubber. That still gives me 3-4X turnover and enough for my scrubber (not sure if I can feed the full siphon to the scrubber or must be submerged for 1000-1500gph?)

If I do this, will this work and be safe?

Left chamber (standpipe and siphon)

-Max overall display drain flow 1000-1500gph

-Left = 1" bulkhead w/ open channel stand-pipe

-Right = 1" bulkhead w/ Full siphon (no valve just wide open)

Right chamber (emergency and return)

-Max return flow (small hole to agitate stagnant water in chamber)

-Left = 1" bulkhead w/ emergency standpipe

-Right = 1" bulkhead w/ return flow that overflows out through the teeth

I could do over the top for return if I need dual emergency 1" pipes if I have a 1" full siphon. Not sure what happens if one of the three pipes fails exactly.

I would put a valve on the siphon drain. U will probably need it to be able to tune the system in so it is silent.

I have never ran dual overflows but that's the only way I can see doing it without modifying the tank. It's not ideal but it should work.U will only be using one of the overflows so surface skimming won't be great.

You can use the hole in the right box for the return. If u drill a few holes in the pipe coming up it should help so the water isn't completely stagnant in that box.

One emergency drain will be enough, if it gets submerged it will turn into a siphon & drain just as much as your main drain. Remember to do as sleepdoc said on the emergency, u will want it just above the overflow so it stays dry under normal operation & water isn't entering that box.

Other then being silent that's another good thing about beans design, it has two failsafes if u have the airline on the open channel. U set the airline just above the emergency and if the water rises that high it turns the open channel into a siphon.

I have never ran dual overflows but that's the only way I can see doing it without modifying the tank. It's not ideal but it should work.U will only be using one of the overflows so surface skimming won't be great.

You can use the hole in the right box for the return. If u drill a few holes in the pipe coming up it should help so the water isn't completely stagnant in that box.

One emergency drain will be enough, if it gets submerged it will turn into a siphon & drain just as much as your main drain. Remember to do as sleepdoc said on the emergency, u will want it just above the overflow so it stays dry under normal operation & water isn't entering that box.

Other then being silent that's another good thing about beans design, it has two failsafes if u have the airline on the open channel. U set the airline just above the emergency and if the water rises that high it turns the open channel into a siphon.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 570