my 1.5" bulkheads required a 62mm drillbit which is like 2.44", we just used 2.5", but the actual 62mm bits are not much bigger than 2 3/8 (2.375" vs 2.44"/62mm) so the difference to go to 1.5" isn't as big as you think, well, not unless you want to use schedule 80 bulkheads, then you need like a 3" bit, but that's totally unnecessary for the pressure levels we deal with, i wouldn't bother.

difference seems minor enough that it might not matter, but if you can find 1 1/4" pvc stuff, then by all means go for that, it's still better than 1" for sure. I'd have considered it for my 120 but i couldn't find any place to get 1 1/4" PVC other than ordering it online, dont think home depot or lowes has 1 1/4"

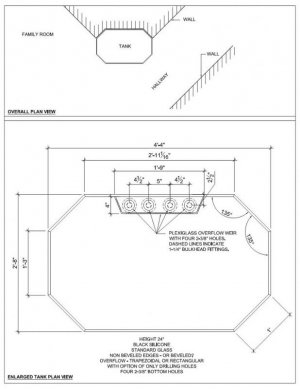

after looking at your plan, i do wonder if your bulkheads are actually too close together. I'd almost consider making the weir wider and adding more space between the bulkheads. Enough space that you can fit either a sideways T plus a 90, or a double 90, in between one or two of the pipes.

Like this basically, if your standpipes are too close, you wont be able to do this without it hitting them:

http://www.saltcorner.com/Articles/ArticlePics/durso1.jpg

Remember, you're gonna want some kinda double 90 setup or T+90 setup for the trickle line, you basically want the trickle line to be a durso standpipe like the one above. The full siphon you could cheat and just make the standpipe really short and put a strainer on it. You might even be able to fit the durso on top of the strainer if you get it all just right, that's like what I did:

http://www.xero.cc/fish/120_overflow_exterior2.jpg

see the double 90 is literally sitting on top of the strainer. that strainer on the bottom is my full siphon and the double-90 is my durso/trickle line, there's a tiny hole drilled in the corner of the other 90 that you can't see in this photo. this acts as the "air hose" or whatever that you'll often see people put on there.

the emergency needs the least room since it can be a straight pipe with nothing else.

i used a low profile strainer because my external weir is only 5" deep, but your weir is nearly tank height so if you make the siphon line sit pretty low in the weir, then you can use something like this even:

http://www.aquariumspecialty.com/me...39433887a97daa66f/s/l/slip-scree-strainer.jpg

then have the durso sit on top.

otherwise, you need to leave enough room so you can do something like this

https://i.ytimg.com/vi/tWMzmiU3wDY/maxresdefault.jpg