Turning the 90 on the open channel sideways won’t really do anything to help. Think of the open channel with just the bulkhead without a 90. If the water level is more then about 1/4” above the bottom of the inlet on the bulkhead it will be loud. Turning the 90 sideways won’t affect this. That is about where the water level has to be for it to be silent. The open channel is essentially what u set the water level to inside the overflow box.

Your issue is that when u have the water level at the correct hieght the slots that u cut in the syphon 90 start sucking air because they are cut to high.

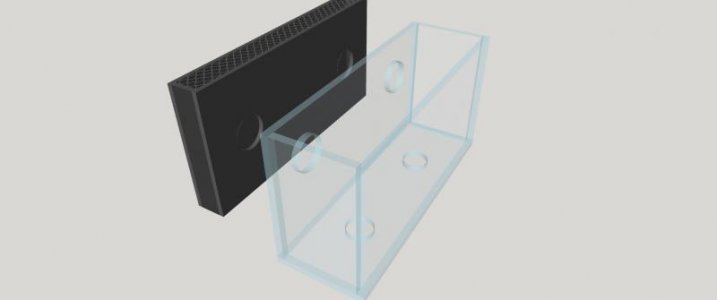

It looked like the bottom of your 90 has more then 3/8” clearance from the overflow box. Being that is the case I don’t know if it will work how I said to test it. I would still try it & cut a piece of pipe 3/8” long & insert it into the 90. It may be enough to get it working. If not even though it sucks, u will have to change out the 90 on the syphon & this time don’t glue it inside of the overflow.

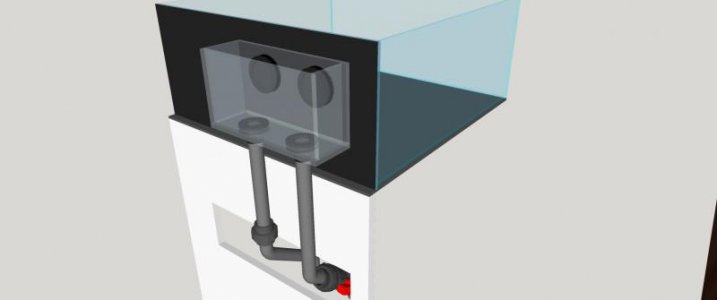

I wouldn’t even mess with the open channel. On a back drilled tank like yours it isn’t the 90 that sets the water level. It is the bulkhead itself. So trying to manipulate the 90 doesn’t really solve anything.

The syphon will purge the air. What will happen is when u start up the return pump the water in the overflow box will rise above normal operation until the syphon purges all of the air. Then the water will lower & go back to the normal operating hieght. So basically it will self regulate to get the air purged, the water will build up until it is enough to purge the air. The emergency may even take a little water at first until it stabilizes.

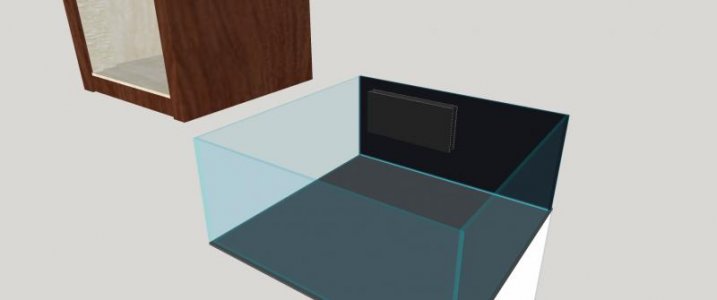

One of my tanks is the same setup as yours with the internal box & back drilled tank. I drilled all the holes at the same hieght just like u. On startup it builds up to where it is right at the emergency but it will eventually purge the air from the syphon & stabilize. It takes it 30 seconds or so. When I setup that tank I even cut the slots in my 90’s like u did, but I had to replace the syphon 90 for one without slots because I was having the same issue as u.

The first thing I would do is cut a piece of pipe to cover the slots on the syphon. Then start the return pump with the valve about 1/2 way closed. Give it a minute & see what it does. U will more then likely have to keep slowly closing the valve to get the water level to rise. Once u can get the water level to rise enough to where the syphon kicks in just let it stabilize to where the water level is consistent in the overflow. Once u get to this point & it is consistent u will know if u need to raise or lower the water level. Make very small changes to the valve until u can get the water level to the bottom of the inlet on the bulkhead. After u turn the valve a small amount give it a minute because it takes a few seconds for the change to show. When u get the water stabilized to about 1/4” above the bottom of the bulkhead u will know if u need to change the 90 on the syphon. If it is still sucking air u will have to change it out because that is around where the water level will have to be. If u have trouble getting the water level to that hieght then u will probably have to also change the ball valve to a gate valve

Your issue is that when u have the water level at the correct hieght the slots that u cut in the syphon 90 start sucking air because they are cut to high.

It looked like the bottom of your 90 has more then 3/8” clearance from the overflow box. Being that is the case I don’t know if it will work how I said to test it. I would still try it & cut a piece of pipe 3/8” long & insert it into the 90. It may be enough to get it working. If not even though it sucks, u will have to change out the 90 on the syphon & this time don’t glue it inside of the overflow.

I wouldn’t even mess with the open channel. On a back drilled tank like yours it isn’t the 90 that sets the water level. It is the bulkhead itself. So trying to manipulate the 90 doesn’t really solve anything.

The syphon will purge the air. What will happen is when u start up the return pump the water in the overflow box will rise above normal operation until the syphon purges all of the air. Then the water will lower & go back to the normal operating hieght. So basically it will self regulate to get the air purged, the water will build up until it is enough to purge the air. The emergency may even take a little water at first until it stabilizes.

One of my tanks is the same setup as yours with the internal box & back drilled tank. I drilled all the holes at the same hieght just like u. On startup it builds up to where it is right at the emergency but it will eventually purge the air from the syphon & stabilize. It takes it 30 seconds or so. When I setup that tank I even cut the slots in my 90’s like u did, but I had to replace the syphon 90 for one without slots because I was having the same issue as u.

The first thing I would do is cut a piece of pipe to cover the slots on the syphon. Then start the return pump with the valve about 1/2 way closed. Give it a minute & see what it does. U will more then likely have to keep slowly closing the valve to get the water level to rise. Once u can get the water level to rise enough to where the syphon kicks in just let it stabilize to where the water level is consistent in the overflow. Once u get to this point & it is consistent u will know if u need to raise or lower the water level. Make very small changes to the valve until u can get the water level to the bottom of the inlet on the bulkhead. After u turn the valve a small amount give it a minute because it takes a few seconds for the change to show. When u get the water stabilized to about 1/4” above the bottom of the bulkhead u will know if u need to change the 90 on the syphon. If it is still sucking air u will have to change it out because that is around where the water level will have to be. If u have trouble getting the water level to that hieght then u will probably have to also change the ball valve to a gate valve

Last edited: