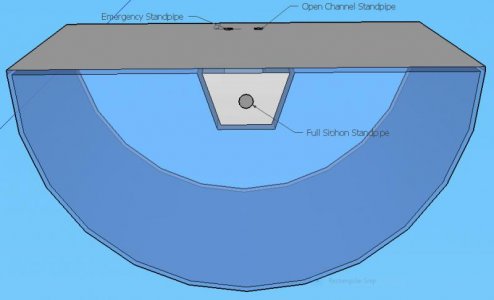

Yes I saw that and may consider doing that, thank you. One other thing I wondering is how do I know I'm getting the perfect amount of trickle in the open line. Bean mentions in his post that anything more than a 1/4" of the cross section of the pipe and you'll start to get gurgling as it starts to "pull" down air. If the 90 is turned down in the overflow box and the exit point is below the water line in the sump, how can one tell if you've got it set right. Is it done by adjusting the valve on the full siphon line until I here minimal noise and that's it?

Basically what he meant was if u connect two 90's together to make a upside U. Where the two 90's attach to each other is what he is referring to as the cross section. If u have a tee with a 90 attached then it would be about 1/8" to 1/4" above the bottom of the inlet on the tee where the 90 attaches to it. To tune it in perfect then yes, u will judge it by the noise & the bubbles exiting the pipe into the sump. I find u start to hear it when it gets more then about 1/8 of the cross section & really loud once it gets above 1/4

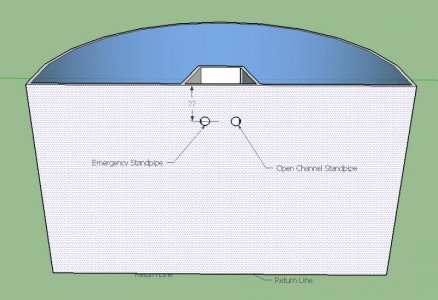

The valve on the syphon will actually adjust the water level inside the overflow box, but the hieght of the open channel standpipe will actually determine where u want the water level to be. U don't want the water level inside the overflow to be way lower then the tank & have the water falling to far over the wier on the overflow box because that would get loud. Usually u want the water level inside the overflow to be less then 2" below the tank waterline so the waterfall going into the box is less then 2". That is one reason not to glue anything inside of the overflow box, sump u can adjust the heights of the standpipes if u see that u need to once u get everything going.

Byw, if u google - Beananimal Bar & Grill - that is beans website. If u look at his silent & failsafe overflow he gives a good rundown of the system. It may be helpful & give u a better understanding so when u do ask a question u may understand the answer better. I don't mind at all helping but I know I'm not great at explaining things in text sometimes & bean explains things better then me. Sometimes I read what I type & it doesn't come out how I mean it to, I'm better with words then typing.