Sorry for bring back up an old section of the thread but my issues where previously discussed in threads #9481-9496 (not sure how to hyperlink that section). Basically, I was not able to return right away to he hobby due to a surgery and recovery, hence my delayed post. At any rate as of recent I'm back at it and have one more question now that things are in the works. The above is post #9495 and references Bean's reply in #9486.

Here's my current situation. Most of my assembly was difficult to contend with/access and all permanently affixed. I ended up keeping the siphon where it was given there was no issue with it. The emergency also was basically fine, except I did raise it some for extra height before emergency kicks in. Lastly, I have changed the Open to have an upturned elbow followed by 2 more forming an inverted "U". I then also placed a vertical section on the inlet of that U extending down in the box, close to the glass to limit livestock access. (I'm thinking I should have omitted that piece now). So now, noise is no longer an issue its dialing in the system. I had previously thought having the airline on the open channel would break siphon/vacuum and be ok with the vertical but that doesn't appear to be whats occurring. Here's an example, I have to fully close my siphon line before the water level rises to the horizontal part of that U before it stops rising. If I have my siphon open as it should be even if only slightly the water level never raises in the overflow box up to the U making it silent, like it is when closed instead it surges up and down. I'm assuming I should just cut off that leg on the open channel and be golden but wanted to check before I go hacking away at it given its easier to remove then to add. I've spent a lot of time and continue to make mistakes, so I'm asking for feedback first this time. Because at this point I would really like to have my system up and running properly to enjoy it rather than getting discouraged by it. Thanks in advance for your help. Let me know if any of the above is unclear or if you have some other question about my specifics I need to outline.

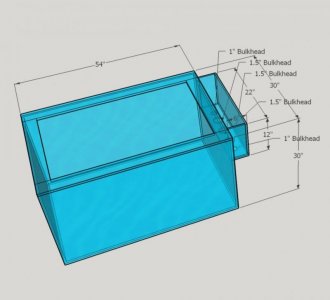

Here's a quick crude diagram of what I have now: