hi bean, thats alot of reading, this must be one of the biggest threads in history.

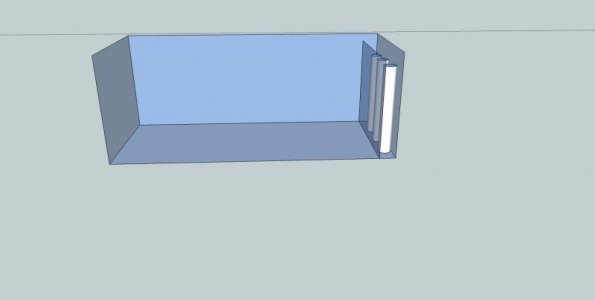

im doing my tank for a freshwater sump that will be plumbed into a wet dry system, therefore the outlets of the overflows will not be submerged and will be probably be a spray bar or 2. will this effect flow rates at all?

also, is it possible to join the two 1.5" drains (not the emergency) into a 2 inch horizontal drain before it enters a spray bar?

thanks alot for you help, ive had a real hard time finding the plumbing parts i need, especially the sanitary tee and the street elbow, i did buy a sanitary tee but its a different size than the rest of my piping even though its classed as 1.5", so i think i might just might replace the 2 sanitary Ts with elbow and keep the emergency with just a normal T

and it will probably have to be normal 1 inch elbows instead of the street elbows as well, unless i find a place that ships internationally

thanks

oh and, is the pipe fittings used pressure pipe fittings? or drain vent (DWV) fitting? they both seem to be different sized piping