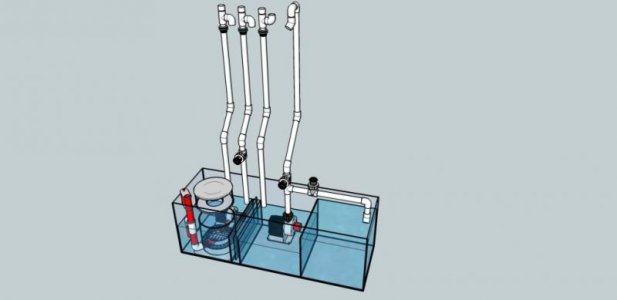

Well maybe, I thought all three were to be the same height as they exit the collection box as mentioned I have shortened the length of the elbow so if breaks siphon before the full siphon drain. mmmmm to change will mean a new box made.

The listed "fixes" where put forth to solve a specific issue. The most common being large bulkheads with a low flow rate, a particular issue that cannot be solved by correcting other implementation errors. But on the other hand, the issue is not that "unsolvable" as the bulkheads can be bushed down to 1". In short, a properly implemented system does not require the mentioned modifications.

"I have shortened the length of the elbow so if breaks siphon before the full siphon drain."

I have been trying to decipher what you have going on, but some of what you are saying does not make sense. If

what siphon breaks before the full siphon drain? There is only one siphon in the system, so there is no other siphon to break... You mentioned something about the "dry pipe" which would be the dry emergency, however, how that evolved into discussion of the open channel (a wet pipe) I don't know. There are no siphon breaks in the system, unless referring to the air vent on the open channel (which prevents siphon, rather than breaks it.)

This system does not start up instantly, not generally anyway. It can take several minutes for the system to sink in. It is normal for the system to be somewhat unstable during start up, it is normal for water to flow in the dry emergency during start up. If it continues for much more than a few minutes, there is something that needs to be addressed.

The only relative height difference that applies is the height difference between the inlet to the siphon elbow, (an easier reference point than trying to describe the "weir" of the stand pipe) and the inlet to the dry emergency. Look at this distance as the head pressure required to "purge the air out of the siphon" or "start the siphon." The problem I saw, when modelling small external boxes, was the needed height of the dry emergency was a bit close to the top of the box.

So I am not really sure what you have going on, nor certain that you have an issue that needs to be addressed.