TheFishMan65

New member

Glass (framed)or acrylic? 2x4s are usually good for a 48 inch tank. Any center legs?

so i just got done building a stand for my frag tank that will be 48x24x16 and 80g total volume. I followed the original plans in this thread and used 2x4's for the entire build. After skimming thru some of the split thread I came across a post that suggested 2x6's should be used for the top box with tanks that are 48x24. Should I rebuild the top box or leave it as it is?

Glass (framed)or acrylic? 2x4s are usually good for a 48 inch tank. Any center legs?

Glass (framed)or acrylic? 2x4s are usually good for a 48 inch tank. Any center legs?

Since your tank is only 16" tall, it would not have the weight the average tank with this footprint would have. The top box should be fine. If your tank is acrylic, topping off the stand with a sheet of 3/4" plywood will support the tank bottom, and add a center rail left to right if there is not one already. You don't need that plywood or center rail with a glass tank. My 120 gallon with this footprint is on 2 by 4's, and so far (20 plus years) it's been OK.

My 120 gallon tank is on a stand that isn't skinned. In fact there is a second tank under it 48 x 24 x 12.I should add that I am not skinning the stand. Its going to be in my basement so there will be no finishing to it. I have 2 cross beams on the top box and two on the bottom box both 16" apart. I was thinking about putting plywood on the top just to make it a little more solid. I know all of the weight is supposed to be on the perimeter of the stand so I could also add additional supports on the perimeter if needed. A friend of mine told me it wasn't sturdy enough and will fall over. Part of me thinks its because he didn't follow these plans and he has had nothing but problems with his stand.

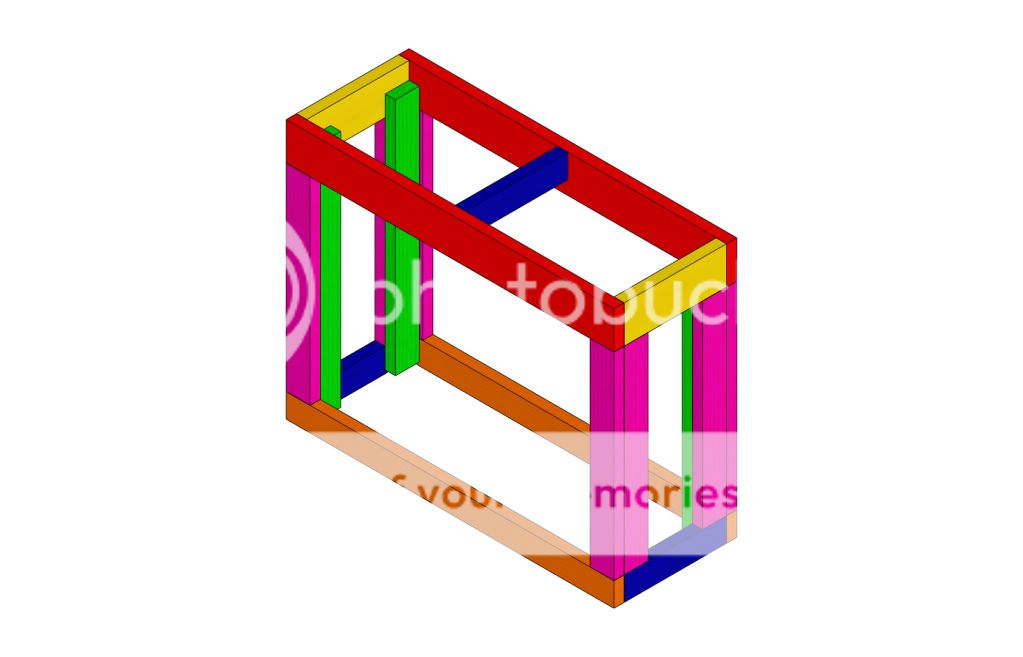

Would 2x3's work for the vertical pieces (purples) for a 75 gallon stand? Would like enough room to slide a 55g into the bottom from the side, so need at least the 13" width.

Also rocket, I think this is your original:

found it at: http://www.reefsanctuary.com/forums/equipment/73534-diy-90gal-stand.html

This thread is about structuring aquarium stands, not about furniture and home furnishings, although useful information about the superficial treatment of the stand exterior is an aside I always value.Poplar is not hardwood for the purposes of this discussion which is furniture and home furnishings. .... Im assume you are confusing my 950 starting point as tree height, its not. It the Janka rating. ....

Don

This thread is about structuring aquarium stands, not about furniture and home furnishings, although useful information about the superficial treatment of the stand exterior is an aside I always value.

Most people building these stands are using primarily SPF (spruce, pine, fir) and they don't have all the tools or skills for working with oak or maple. The template calculator here appears to be based on using construction grade SPF. I don't remember either you or me introducing the topic of poplar, but for those whose only other practical choice is SPF, poplar does have the visual advantage of a prettier grain that stains and finishes nicer than SPF, and the virtual lack of defects and knots so common in SPF. I do have some poplar on the face of five of my own aquarium stands, and after six years, it looks good still. My aquarium stands don't suffer a whole lot of the wear and tear that oak or hard maple would hold up so well to. Poplar has many more uses than the two you limit it to, and there is no point to depriving aquarium stand makers of another option. It has a more moderate price than oak or walnut, which are certainly more beautiful woods to finish.

This thread is about structuring aquarium stands, not about furniture and home furnishings, although useful information about the superficial treatment of the stand exterior is an aside I always value.

You know I am not confusing your Janka remark with tree height. You are not dumb. You are being snide and pernicious while playing dumb. You are much better than that.

Most people building these stands are using primarily SPF (spruce, pine, fir) and they don't have all the tools or skills for working with oak or maple. The template calculator here appears to be based on using construction grade SPF. I don't remember either you or me introducing the topic of poplar, but for those whose only other practical choice is SPF, poplar does have the visual advantage of a prettier grain that stains and finishes nicer than SPF, and the virtual lack of defects and knots so common in SPF. I do have some poplar on the face of five of my own aquarium stands, and after six years, it looks good still. My aquarium stands don't suffer a whole lot of the wear and tear that oak or hard maple would hold up so well to. Poplar has many more uses than the two you limit it to, and there is no point to depriving aquarium stand makers of another option. It has a more moderate price than oak or walnut, which are certainly more beautiful woods to finish.

Would a 48x24x24 be ok on a 39" tall stand be stable? Can't having it fall over. It would kinda suck.

I have a 29 gallon Biocube that I need to build a stand for. The space I would like to put it is 24"Dx36"W. This is a corner between 2 doorways. I would like to fill this space as much as possible, yet keep as much open in the bottom as possible for a future upgrade. Couple of questions:

1. Should I build the skeleton to fit the cube now, then expand it to cover the rest of the area?

2. Would it be possible to build the whole thing out of 3/4 ply, more like a traditional cabinet?

I have all the tools, and have done some woodworking in the past, but never anything that's going to be a nice piece in the living room.

Hardwood vs Softwood is based on the internal structure of the wood vs its actual strength/hardness. Poplar is 22% stronger than pine when both are green. Given the lack of quality in the 2X material typically available, I use a Modulus of Elasticity of 1.0*10^6 for my calculations. Yellow poplar has a MoE of ~1.5*10^6 when dry so it is in affect 50% more ridged then pine. Given that most poplar found at big box stores is 1X material, it is 1/2 the thickness so only 75% as strong as the pine 2X of the same width.

What does all this mean? It means that to make a poplar frame based on my template for a 90g tank, the upper frame should be 1X6 instead of a 2X4. However, this same frame can be finished as is where as the 2X4 frame would look best with an exterior covering.

Remember folks, this is just a template. When I built my own stand, I didn't use this design directly, I modified it to fit my needs. There are a number of ways to get the same result, it all depends on the tools available and the skill set each person has.

Please don't take my word as gospel, I am as likely to make mistakes as the next person. Do your own research, make up your own mind, and go from there.

RocketEngineer