bhbell

New member

As MDF takes on water and swells it loses structural integrity so not something you want to have happen...

In this case it would be in place of foam and not part of the structure.

As MDF takes on water and swells it loses structural integrity so not something you want to have happen...

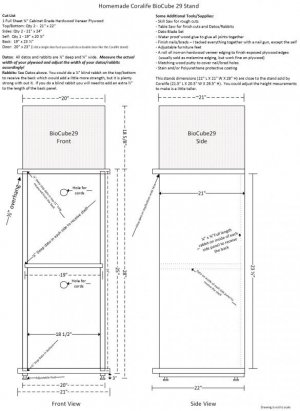

There are a lot of great looking stand builds in this thread! It inspired me to pull out my table saw and build a stand for my new BioCube 29. It only took one sheet of Cabinet Grade Plywood and we had it finished in a weekend. The only thing left is to mount the door.

I used the dimensions of the Coralife stand as a starting point for my design and lowered it slightly so that we could look directly into the cube at eye level while seated on our couch.

I am not an expert draftsman but I have also included the basic plans that I drew up that someone could use for their own build. I used adjustable feet which worked fine for the cube, but one could also build a rectangular base from the same sheet of plywood and use shims to level it.

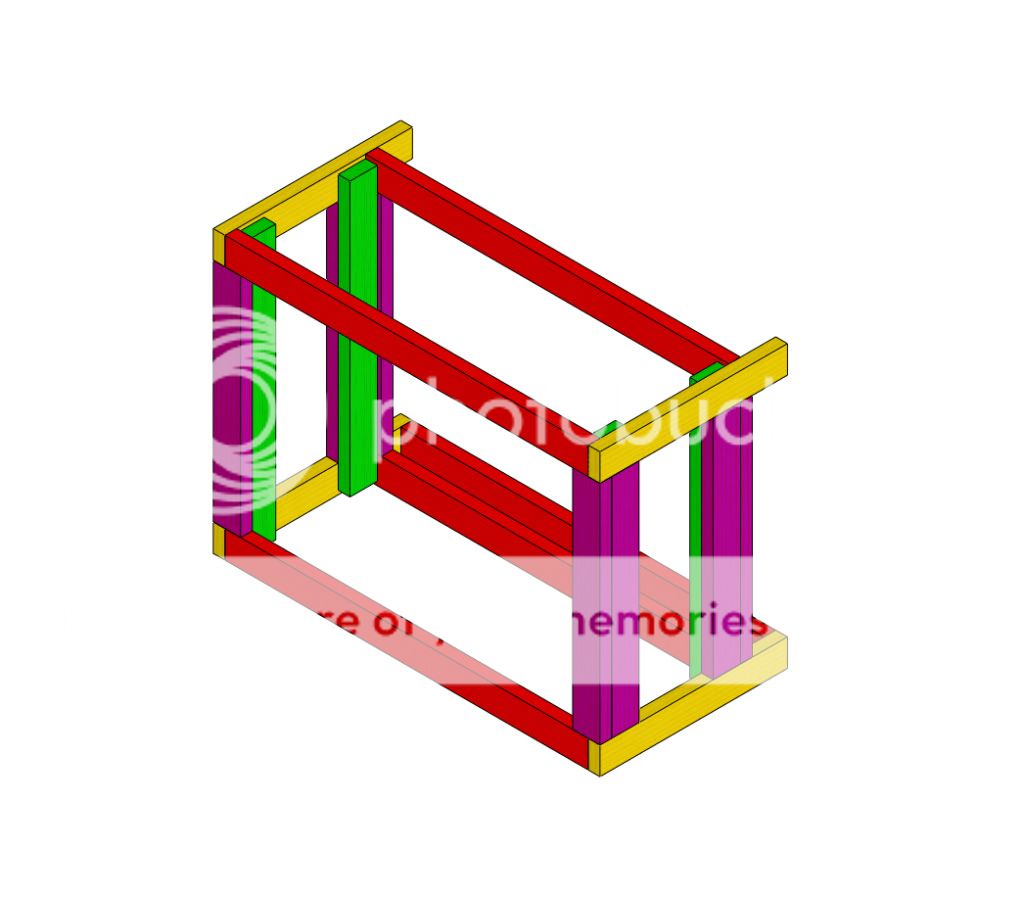

Datos and Rabbits to receive the sides and back:

View attachment 329910

View attachment 329911

Before adding the stain and polyurethane

View attachment 329912

Completed, the tank is now cycling, I just need to mount the door

View attachment 329914

Here are the plans, if anyone is interested I can post or send a PDF version.

View attachment 329915

I was a lot of fun building it with my son. Let me know what you think!

Problem is, the main DT tank is 18"1-1/2 wide, and the sump is the same width

How would I make a stand now to accommodate the same width sump?

Lastly , I always get stuck making the doors, so I never end up making them

Is their a thread to show how make doors?

Thanks for your help

The layout I find easiest is below:

The gap behind the display lets the sump have enough room plus all your plumbing and wires now have a space to run.

I don't know of a thread showing how. The more detailed the door, the more expensive the tools needed to produce them. The simplest method I've used is 1X surrounding a central 1/2" plywood core. The surround is joined together with pocket screws while the plywood is kept in place using biscuits. I used this concept for the panels on my 125g hood build.

Here's a link to how I did it.

HTH,

I have the same tank and I did mine with only 2x4. Your stand seems like it would be sufficient without a center brace. Why not go with 2x4s instead of 1x4 and 1x6?

Rocket, just built a stand for my 125. Ran into the problem where its not quite level and has a wobble. So if I push down on the right front side, the back left side will come off the ground a few mm's. If I push back left, same happens to the front right. I stood on one corner, and had my gf stand on the other and it seemed to press it down so that all was touching. Is this gonna cause too much stress when I have 1000 lbs of water on top of it?

Wow, this is a HUGE thread with TONS of great information and inspiration! Thanks to RocketEngineer for helping us all out!

I'm designing my 75 Gal stand. In order to have enough room for my sump, ATO jugs, and reactors I removed two of the vertical supports in back.... is this okay or what other way can I help support the top? is there a way I can make the stand 6" wider??

Rear view: