I'm designing a new in-wall aquarium setup for the basement of my new house I'm building.

RocketEngineer - thank you for starting this thread, the initial post helped me tremendously. I'd appreciate your input/feedback on my design.

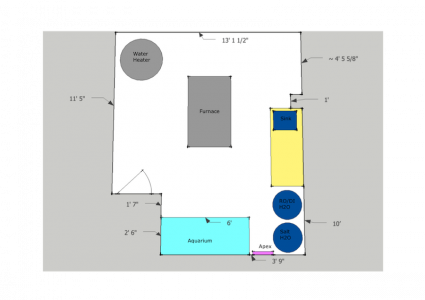

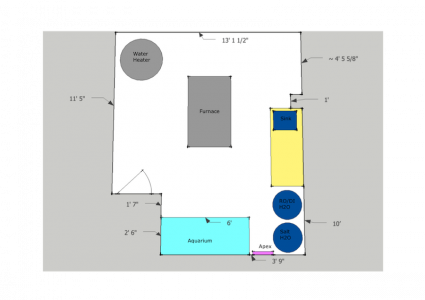

A little bit of background on the overall setup: the tank will be in-wall with a large fish room behind it. As you look at the front of the tank, both the front and left side will be exposed and visible. Here's a rough layout of the room:

The tank will be 72"x30"x30". The top of the stand will be 40" above the floor.

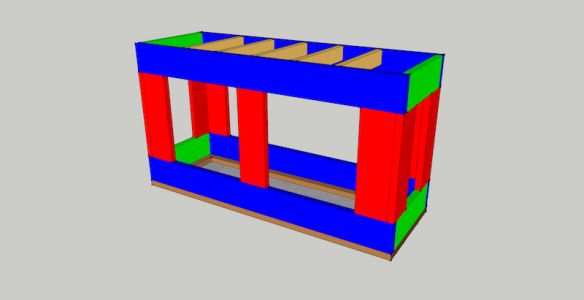

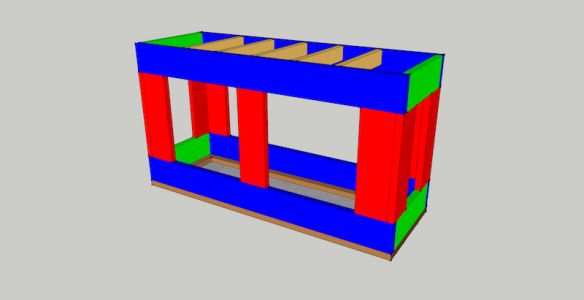

Here's the design of the stand:

This view is looking at the front of the tank, as if you were looking into the fish room. The top will be covered by plywood.

The stand is primarily 2x8 - the blue, red, and green are all 2x8. The brown lateral supports at the top are 2x4s.

What aren't shown are the supports that will go in each corner. I am planning to use a 4x4 in each corner.

Because the tank is in wall, I kept the stand on top of the 2x4 that will be used for the walls on either side of the tank. That necessitated adding 2x4s around the rest of the stand.

A few questions:

1) Is this sturdy enough and structured well enough to support the weight of the tank, rock, and water?

2) are 4x4s in each corner overkill?

3) Is 1/2" plywood sufficient for the top or should I increase to 3/4" or 1"?

Thanks in advance for your help!