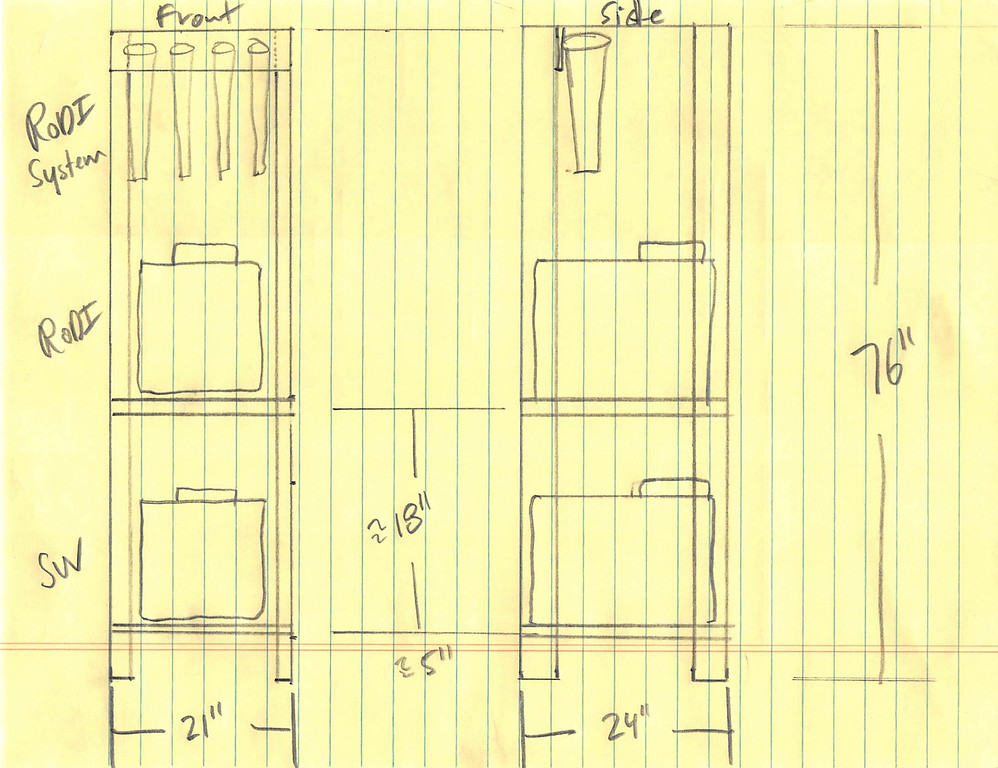

I have a question. I am gearing up to build a stand for a 22g Long tank. It is 36x12x12. However, I plan to add an overflow section on the side and need to accommodate for this as well. By my calculations, that would put my stand at roughly 42" in length. My question is, I have always built stands by way of RocketEngineer's specs. They have been overly done, but I have never had to second guess whether or not they were good enough. With this upcoming build, I'd like to keep the labor less intense and the costs fairly lower than my typical DIY $250-$300 wood stand range.

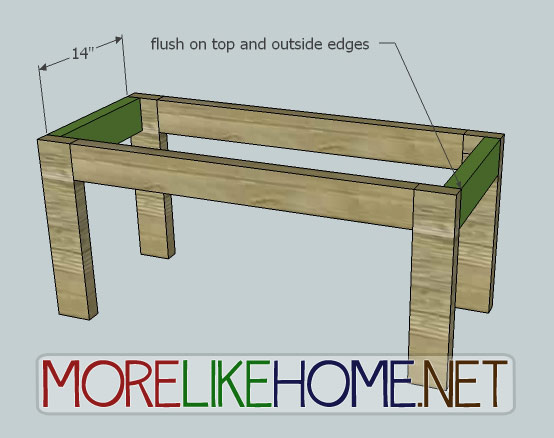

With that being said, I am aiming for making something similar to this (from Pottery Barn):

Here's the link in case you can't view that pic.

http://www.potterybarn.com/products...&&coutdoor-bars-buffets#viewLargerHeroOverlay

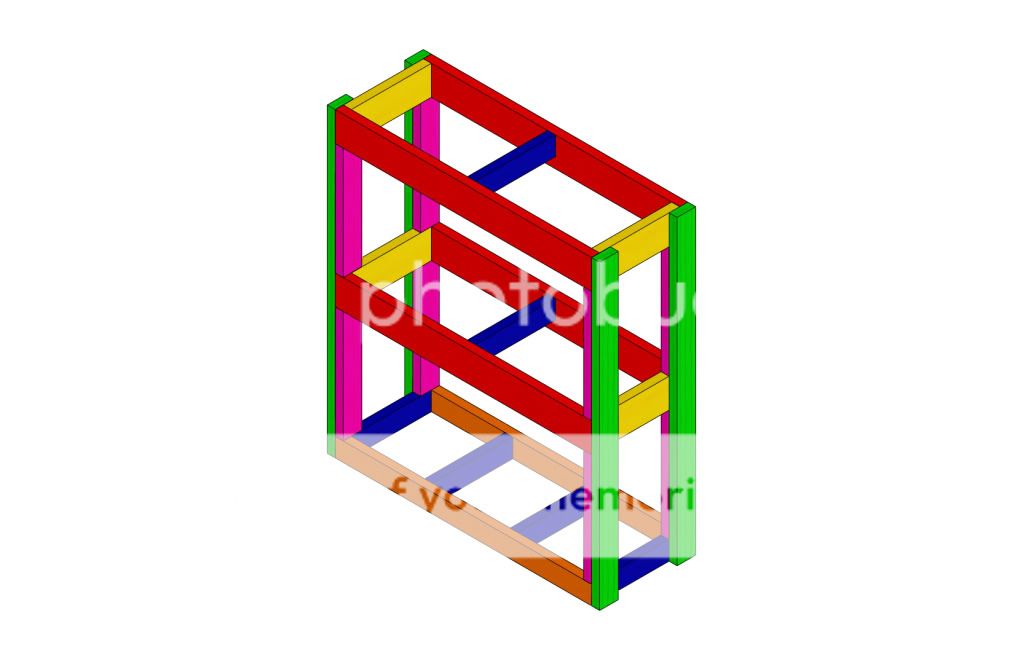

Obviously I do not want all that front storage and such, but what I am looking at is the structure of the stand. I want to use posts like the ones pictured vertically here. I am not sure if these are 2"x2" wood pieces, but would like to use something similar. My goal is simply to have the uprights, the long run wood, which I think I may be able to get away with 1"x4" and I would use a Kreg Jig in order to maximize on the space

inside the stand for sump and other stuff. I do not plan on having the whole thing as high off the ground as pictured, but would like it at least an inch or two off the ground.

I do not plan on fully skinning it. On the back-side, I plan on adding a cut out of a plywood sheet that would almost cover the whole back side. This would add structural integrity to the whole stand, but I am wondering if this alone will be enough to prevent racking. Keep in mind I live in California.

Any help will be greatly appreciated.