Patrick Cox

Active member

Without the pink pieces, the only thing holding up the box frames are the nails/screws and that's not something I would trust.

If you are going the pocket screw route, mount the pink pieces to the underside of the red and yellow ones that way and eliminate the green boards. If you have the room, you could run the green boards up the back to help tie everything together.

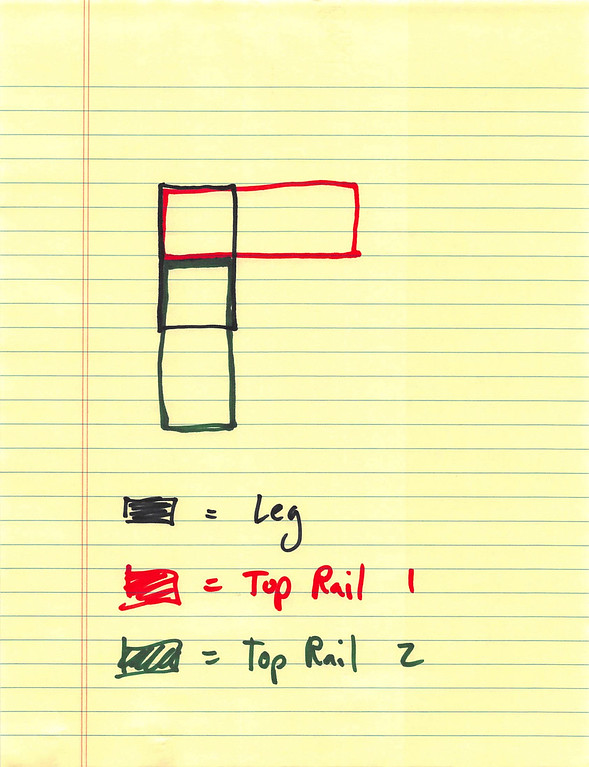

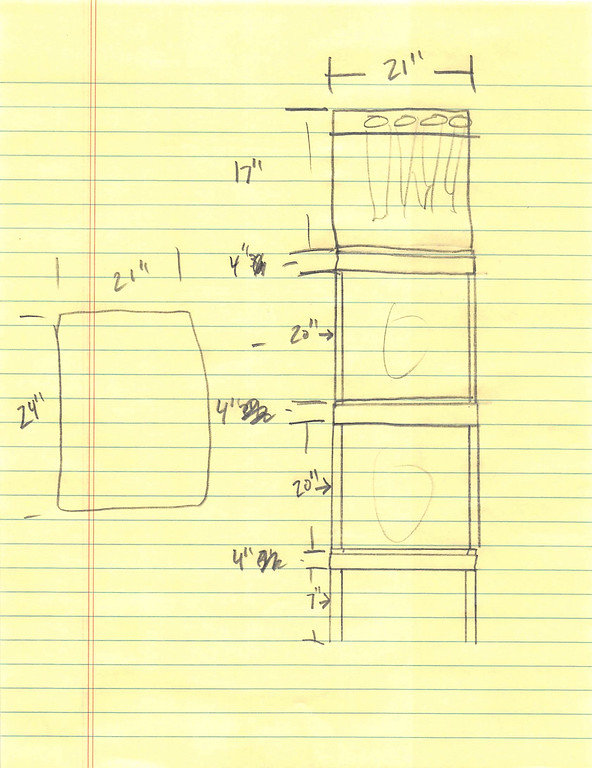

One more question - would you attach the rails to the legs in this manner?... (So each 2x4 rail resting on half of the 2x4 leg.)

Or, what if I built each level of the stand separately so it rested on the one below? Wouldn't this transfer more load to the legs rather than the pocket screw joints?

Last edited: