You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lets see those steel stands!

- Thread starter MeuserReef

- Start date

MeuserReef

Welcome to the next level

<a href=showthread.php?s=&postid=11956315#post11956315 target=_blank>Originally posted</a> by Konadog

Here's mine, sprayed with Line-x truck bed liner:

OK... the bedliner looks AWESOME. Do you mind sharing how much it cost you to have this done? Im in truck country (TX) so finding this service will likely be alot easier (and hopefully cheaper) than the powdercoating. Not quite as durable as the PC, but realistically... Im sure its fine for this application.

What size tank is that stand for?

Did you weld it together yourself?

I'll wait to hear a response from them, but I know you can buy spray cans of the bed liner, as well as gallon cans of them at the local auto parts store(oreilly,autozone, etc) I know the spray cans are 8-9 bucks a piece. Again, they could have used professionals but I know the auto parts stores are a option too.

kcress

New member

<a href=showthread.php?s=&postid=11955614#post11955614 target=_blank>Originally posted</a> by MeuserReef

kcress, I appreciate your valuable assistance in this thread.

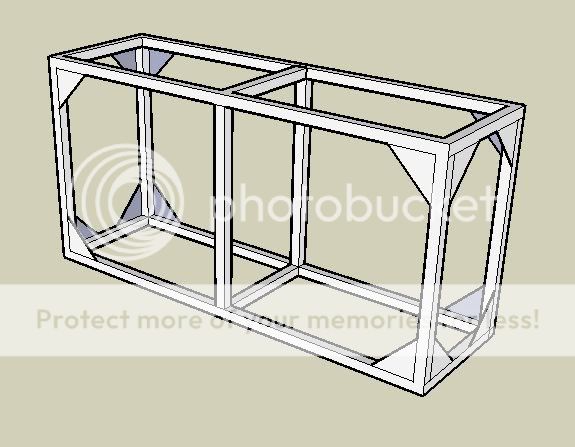

I like the changes that you suggested and have changed the design a bit. The corner braces are 6"x6"x8.5" triangles.

FRONT VIEW (version 2)

Those look great and will work well too.

I liked the idea of using the flat angle pieces in the corners for mounting surfaces for my exterior cabinet that I will have covering this. Im planning on making the wooden exterior "skin" removable so I can maintenance the sump/components as well as clean any spills that will most definetly happen along the way. This tank will be in my living room that will have brand new hardwood flooring so I want to make sure that any spils wont hurt the floor (long term).

Nice idea. You might consider making a 1/8" thick plexy pan to contain the inevitable drips and spills.

As far as sump access, Im using a 20L for a sump so Im sure it will fit without having to remove the center brace. One challenge that I have is that ALL equipment (except DIY Chiller) will have to live in the stand under the tank. If this means that I have to have a smaller sump... so be it. I actually cant go too big with the sump as it will take up too much valuable space that could be used to house other equipment.

If your ends are removable then you can slide in the sump regardless of center bracing anyway.

With regards to your suggestion that I split the top section to provide additional support for potential plywood; Do I really need these supports if I dont plan on using plywood? My tank is made of glass and has the plastic trim that supports the weight of the tank along the perimeter. I have always made my stands for these types of tanks open so that they only support the tank under/along the trim. Suggestions/concerns with this? (The largest tank that I have built a stand for using this method is a 55 gallon, about 1/4 of the weight of my new tank)

Nope plywood need not apply. Nor more braces. Let me just check. Where abouts are you located? Earthquake possibilities would suggest a tiny mod that I would do, but otherwise is likely not needed. See, around here, an earthquake could actually move a tank. I had one move on me. Luckily it was on a large surface so it just moved elsewhere on the surface. It was a 55g. Of course a bunch of the water landed on my brand new phone/answering machine. This led to about 30 phone calls to people in my index, about 2 days later, unbenounced to me. LOL!

Anyway, as you can imagine if a framed tank siting on that relatively small tubing area shifted you would have a big problem. So if there is any chance of movement, you would want some little tabs that would block the tank from shifting. You could put two on those back gussets and one each on the side gussets,(four total) and none on the front. They need be very little like one inch tabs that you screw on with a single screw, after the tank is in place.

-Are these supports critical if Im not planning to use any sort of material between the tank and the stand?

Nope, not in your case.

-Should I use plywood between the stand and tank?

I probably would, but it sure isn't required. You definitely want to make sure that top surface is FLAT though

BTW be sure and pick up a bunch of scrap or short pieces of that tubing and practice until you are confident. You don't want to get 20 welds in and blunder away your material.

Konadog; That looks like one stout stand. Crazy jink there in the back. Looks nice! That jink for your overflow?

What wall thickness did you use? Looks like 3/16 or thicker.. That 1-1/2" tubing? Looks a little bigger in the pictures.

dngspot; Yeah the shear there would be sadly lacking without your siding, which certainly works well too. Nice and clean setup.

I was lucky enough to have a friend that worked for Line-x at the time, so I only paid for material. I was told at the time that they would have charged around $250 for the job. The big problem is the sprayer that is used, it's meant to spray flat surfaces (truck beds) not thin pipe. Lot's of over spray, which equals wasted product and your $$. One benefit of a thick material is the sound deadening properties of it. Steal stands can resonate a pump hum or vibration. This stuff you can hit with a hammer and only hear a slight thump.<a href=showthread.php?s=&postid=11957527#post11957527 target=_blank>Originally posted</a> by MeuserReef

OK... the bedliner looks AWESOME. Do you mind sharing how much it cost you to have this done? Im in truck country (TX) so finding this service will likely be alot easier (and hopefully cheaper) than the powdercoating. Not quite as durable as the PC, but realistically... Im sure its fine for this application.

What size tank is that stand for?

Did you weld it together yourself?

It was made for my 225 gallon tank, 60" long, 30" deep, and 40" tall. I hate bending over to look at my tank, so I had it built tall.

As far as welding, No, again I'm lucky enough to have a welder at work so I gave him what I wanted and he welded it together for me. I didn't have any corner bracing put on it as it's not needed. This thing would support a train without flexing. I think we tend to overbuild things, thinking about problems we see with wood stands.

MeuserReef

Welcome to the next level

Thanks kcress

BTW be sure and pick up a bunch of scrap or short pieces of that tubing and practice until you are confident. You don't want to get 20 welds in and blunder away your material.

This is likely what I will do. Im also really liking the truck bed liner that Konadog used on his stand. Im very interested in seeing what he spent to have that job done.

Im in Houston, TX so theres pretty minimal earthquake risks (pretty much zero) here. Our bigh threat is Hurricanes but thats a whole other animal .

.

How difficult do you think its going to be to cut the flat steel that will be used to make the triangle corner braces? Perhaps I can find these pre-cut...?

If only I had access to the OCC shop...

BTW be sure and pick up a bunch of scrap or short pieces of that tubing and practice until you are confident. You don't want to get 20 welds in and blunder away your material.

This is likely what I will do. Im also really liking the truck bed liner that Konadog used on his stand. Im very interested in seeing what he spent to have that job done.

Im in Houston, TX so theres pretty minimal earthquake risks (pretty much zero) here. Our bigh threat is Hurricanes but thats a whole other animal

How difficult do you think its going to be to cut the flat steel that will be used to make the triangle corner braces? Perhaps I can find these pre-cut...?

If only I had access to the OCC shop...

Did you see the post above yours?<a href=showthread.php?s=&postid=11958746#post11958746 target=_blank>Originally posted</a> by MeuserReef

This is likely what I will do. Im also really liking the truck bed liner that Konadog used on his stand. Im very interested in seeing what he spent to have that job done.

kcress

New member

So konadog I ask again; Tube size? Thickness?

MeuserReef; If you have a steel fab place in town, you can draw up the triangles and ask them how much for X pieces. Or you can get just flat stock and they can be squares that get sheared out of 8 inch flat stock.

You could always just get the flat stock and cutting-torch it yourself. Make a jig so they all come out the way you want with nice straight clean cuts.

Or get squares,(which they just shear like paper), and torch the diagonal for triangles.

The place you get the tubing at would likely have the flat stuff too.

MeuserReef; If you have a steel fab place in town, you can draw up the triangles and ask them how much for X pieces. Or you can get just flat stock and they can be squares that get sheared out of 8 inch flat stock.

You could always just get the flat stock and cutting-torch it yourself. Make a jig so they all come out the way you want with nice straight clean cuts.

Or get squares,(which they just shear like paper), and torch the diagonal for triangles.

The place you get the tubing at would likely have the flat stuff too.

MeuserReef

Welcome to the next level

<a href=showthread.php?s=&postid=11959073#post11959073 target=_blank>Originally posted</a> by Konadog

Did you see the post above yours?

I hate cross posting!!!

Thanks for the info Konadog! Did you purchase the steel retail or was that yet another "hookup"?

MeuserReef

Welcome to the next level

<a href=showthread.php?s=&postid=11959647#post11959647 target=_blank>Originally posted</a> by Konadog

Yep, another hookupGota do it when you can!

Hey... no ones mad about that! A little envious... but definetly not mad.

I found a place here in town that I was told would be able to provide the 1.5" square tubing (1/8" wall thickness).

I have never bought this stuff so I have no idea what a "fair market" price is. What should this type of product sell for (per ft).

kcress

New member

Sorry but there is no fair market price. A big part of the cost of this stuff 2.2lbs/foot is shipping and volume.

Also this stuff at fab place may be left overs from a standard structural job and so may be heavily discounted to "get rid of it".

I suspect that if $150 for painting is cramping your style.. you will be asking next about wooden stands. LOL

You need to ask the place how much and see if you can afford it.

You are in Houston.. I can't think of many places that would have more 'shops'. Hit the yellow pages and do the standard. Call three places and ask for quotes.

Better yet: Make a detailed list of what you need.

Material: Steel, 1-1/2" square tubing, 1/8" wall

(4) 57"

(6) 40"

etc, etc,

Material: steel, 1/8", flat stock

(16) Right Triangles, 6" x 6"

Each shop will charge cutting fees.

Fax it to three suppliers and get the quotes.

Also this stuff at fab place may be left overs from a standard structural job and so may be heavily discounted to "get rid of it".

I suspect that if $150 for painting is cramping your style.. you will be asking next about wooden stands. LOL

You need to ask the place how much and see if you can afford it.

You are in Houston.. I can't think of many places that would have more 'shops'. Hit the yellow pages and do the standard. Call three places and ask for quotes.

Better yet: Make a detailed list of what you need.

Material: Steel, 1-1/2" square tubing, 1/8" wall

(4) 57"

(6) 40"

etc, etc,

Material: steel, 1/8", flat stock

(16) Right Triangles, 6" x 6"

Each shop will charge cutting fees.

Fax it to three suppliers and get the quotes.

TeeLapia

In Memoriam

what type of steel were you looking into as well? There are steel grades on top of thickness, and size.

I believe T06 would be good. You should look up "supply" under the yellow pages, and you can get all the steel supply companies that are local. When they are bought in bulk it is cheap, esp building the stand, it's the labor in welding that will run $$$.

I believe T06 would be good. You should look up "supply" under the yellow pages, and you can get all the steel supply companies that are local. When they are bought in bulk it is cheap, esp building the stand, it's the labor in welding that will run $$$.

Another place you may look for your tubing is a scrap yard. Where my office is located I have two steel yards and one scrap yard to compare prices. It's worth it to call around, some places charge less for stuff they sell everyday. It's usually cheaper per foot the more you buy.

MeuserReef

Welcome to the next level

<a href=showthread.php?s=&postid=11960344#post11960344 target=_blank>Originally posted</a> by kcress

Sorry but there is no fair market price. A big part of the cost of this stuff 2.2lbs/foot is shipping and volume.

Also this stuff at fab place may be left overs from a standard structural job and so may be heavily discounted to "get rid of it".

I suspect that if $150 for painting is cramping your style.. you will be asking next about wooden stands. LOL

You need to ask the place how much and see if you can afford it.

You are in Houston.. I can't think of many places that would have more 'shops'. Hit the yellow pages and do the standard. Call three places and ask for quotes.

Better yet: Make a detailed list of what you need.

Material: Steel, 1-1/2" square tubing, 1/8" wall

(4) 57"

(6) 40"

etc, etc,

Material: steel, 1/8", flat stock

(16) Right Triangles, 6" x 6"

Each shop will charge cutting fees.

Fax it to three suppliers and get the quotes.

Thanks kcress.

At this point... I dont really have a budget for the stand. The 120 gallon aquarium that I just purchased will probably take me to the limits of my monthly tank operating budget, as well as the wife's "tank upgrade endurement ability"....therefore Im planning this tank build as though it is my "dream" tank. I want to make sure that I buy/build based on quality, not necessarily just by price. I would have no problem paying $150 to spray a steel tank with the truck liner so long as I felt confident that it would last 15+ years.

I have found a few places local that I will be calling tomorrow. I will post my results for reference. I will try to include some scrap yards in my calling.

<a href=showthread.php?s=&postid=11960583#post11960583 target=_blank>Originally posted</a> by TeeLapia

what type of steel were you looking into as well? There are steel grades on top of thickness, and size.

I believe T06 would be good. You should look up "supply" under the yellow pages, and you can get all the steel supply companies that are local. When they are bought in bulk it is cheap, esp building the stand, it's the labor in welding that will run $$$.

Thanks for the tip.

activecactus

New member

Here's the stand that I made for my 29 gallon. I used the angle iron from an old queen size bed frame.

MeuserReef, when you do get to the point of getting a welder to price things, be sure to tell them that you want everything sealed, no open ends. This will help with places rust can form. When it's sprayed/painted with what ever you go with, it makes a nicer look too.

There are other truck bed liners besides Line-x, look at Rhino or some of the others (even self applied) as you won't have the same wear as a truck bed. The reason I went with it (besides having a contact) was that I'm to stupid to have a stand powder coated. I will chip it the first day I have it and it will start rusting, blistering, and then popping. I just couldn't do it that way.

There are other truck bed liners besides Line-x, look at Rhino or some of the others (even self applied) as you won't have the same wear as a truck bed. The reason I went with it (besides having a contact) was that I'm to stupid to have a stand powder coated. I will chip it the first day I have it and it will start rusting, blistering, and then popping. I just couldn't do it that way.

MeuserReef

Welcome to the next level

<a href=showthread.php?s=&postid=11961922#post11961922 target=_blank>Originally posted</a> by Konadog

MeuserReef, when you do get to the point of getting a welder to price things, be sure to tell them that you want everything sealed, no open ends. This will help with places rust can form. When it's sprayed/painted with what ever you go with, it makes a nicer look too.

Im going to be welding this one

With regards to "sealed", Im guessing that you are talking about the open ends of the tubing, right?

activecactus...

tonyf...

... awesome jobs on those stands.

Similar threads

- Replies

- 3

- Views

- 104