You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silent and Failsafe Overflow System

- Thread starter JohnL

- Start date

uncleof6

Active member

Okay, so just like in your drawing eh? That's what I had planned, but all this talk about bends had me a bit concerned.

My head spins around on occasion, and too much gets said. I have not done a system yet with a dead straight drop from the overflow to the sump. 2 - 45's in each pipe will usually be needed, unless you come out the bottom of the tank. The problem comes with a 90 jog in the open channel, and long horizontal runs...

rrasco

Active member

My head spins around on occasion, and too much gets said. I have not done a system yet with a dead straight drop from the overflow to the sump. 2 - 45's in each pipe will usually be needed, unless you come out the bottom of the tank. The problem comes with a 90 jog in the open channel, and long horizontal runs...

Yep. I gotcha, that's what I thought. I will be using two 45s to get under the stand since my tank is drilled in the back. Thanks.

nurjrk

New member

Well, I've got water in and running a test. Seems to be running well, except.....The bubbles don't seem to go away. Starts up fine, tested mult times, but bubbles never go away. It's prety quiet but not dead silent. I can hear the bubbles churning in the siphon drain. Any ideas?

Thanks in advance for your help.

Thanks in advance for your help.

uncleof6

Active member

Well, I've got water in and running a test. Seems to be running well, except.....The bubbles don't seem to go away. Starts up fine, tested mult times, but bubbles never go away. It's prety quiet but not dead silent. I can hear the bubbles churning in the siphon drain. Any ideas?

Thanks in advance for your help.

You have an air leak in the siphon standpipe or line somewhere. Water flow, passing the "leak," will draw in air just like a venturi. Unless the siphon inlet is drawing air because it is too close to the surface, this is the only other possibility. This air leak, may not leak water.

rrasco

Active member

I finally got my tank plumbed and was able to test this system. It works good, but I have a problem getting the siphon started automatically. If I remove the siphon cap, water begins to flow, so then if I cap it off, the siphon starts and the system stabilizes. Why am I having to prime the siphon manually?

uncleof6

Active member

I finally got my tank plumbed and was able to test this system. It works good, but I have a problem getting the siphon started automatically. If I remove the siphon cap, water begins to flow, so then if I cap it off, the siphon starts and the system stabilizes. Why am I having to prime the siphon manually?

Couple things. First how deep in the sump are the outlets? Second: At what level is the air hose for the open channel?

If the pipes go deeper than an inch, there can be starting issues. It will be more difficult to purge the air from the line.

If the open channel trips (the air hose gets covered with water) before the siphon kicks in, the open channel will not necessarily allow the siphon to start, by drawing too much flow. Check your tripping order, per the original design. Siphon kicks in, if water level rises, the dry emergency kicks in. If for some reason the water level continues to rise, the air tube is submerged, and the open channel goes to siphon.

In some cases, the open channel inlet needed to be raised a half inch or so.

rrasco

Active member

Couple things. First how deep in the sump are the outlets?

Probably around 5 inches or so. I will try shortening them.

Second: At what level is the air hose for the open channel?

I don't have an airline installed yet. I ordered john guest fittings, which I received, but didn't realize they sent 5/8 instead of 3/8. My cap is tapped for 3/8. I'll have to get new fittings or tap the cap to 5/8 before I can install it. I was under the impression the airline was there as a fail safe, not as a necessity to start the system.

Having said that, the siphon did start when I initially filled the tank, whereas the sump was still empty. With that in mind, I think I will try shortening the outlets in the sump to see if that gets the siphon self priming.

Thanks.

uncleof6

Active member

Probably around 5 inches or so. I will try shortening them.

I don't have an airline installed yet. I ordered john guest fittings, which I received, but didn't realize they sent 5/8 instead of 3/8. My cap is tapped for 3/8. I'll have to get new fittings or tap the cap to 5/8 before I can install it. I was under the impression the airline was there as a fail safe, not as a necessity to start the system.

Having said that, the siphon did start when I initially filled the tank, whereas the sump was still empty. With that in mind, I think I will try shortening the outlets in the sump to see if that gets the siphon self priming.

Thanks.

Yes it is a failsafe, not a starting aid. If the air tube inlet is lower than the emergency inlet-- it will trip too soon, it can stop the siphon from starting. But if you have no air tube on it, that would not be the trouble in this case.

Outlets to the pipes 1" or less below the water surface. Deeper will cause problems.

I'm in Temecula, not a lot of choices for lfs, any good store in San Diego. Thanks

I am going to give a shamless plug to AquaSD. Will is a great guy, customer service is top notch. They just moved into a new building. They always have crazy looking corals. You can find them on the web as well.

WOW! Great thread, just in time too. I picked up a 120 about a month ago and was going to do a C2C with a dual Durso that drains into one common drain, I did that on my last tank. I think I like this design a lot more. I have already drilled the three holes for the overflow. Planed a CL with a Sanpper/Dart before I saw the BA recommendation, holes already drilled, pump already purchased. Worst part about a new build, drilling 5 holes in a glass tank, some almost three inches across. Talk about nerves of steel.

uncleof6

Active member

a couple of quick questions.

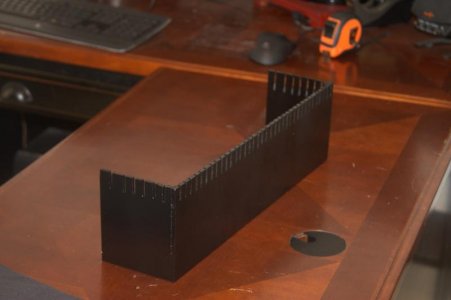

what have you all been using to make the teeth in the drains? hand saw?

and what has been used for tapping the open line? Not sure if there are special ones for pcv.

The teeth are unnecessary, and just a 1/4" NPT tap, no difference (or 3/8" NPT whatever the case may be.)

gone_fishing

New member

a couple of quick questions.

what have you all been using to make the teeth in the drains? hand saw?

and what has been used for tapping the open line? Not sure if there are special ones for pcv.

For the drain pipe slots I used my husband's table saw (not sure that is what it is called, it has big blade and you move it down to cut what's underneath) I had used it to cut the PVC along the way so I was pretty comfortable with it by then. So I held a long piece of PVC towards the end of the blade and dropped the saw down enough to make a slot. Worked great, a few mess ups, now I don't have to worry about any fish, etc.

, getting sucked into the pipes.

, getting sucked into the pipes.Floyd R Turbo

Either busy or sleeping

a couple of quick questions.

what have you all been using to make the teeth in the drains? hand saw?

and what has been used for tapping the open line? Not sure if there are special ones for pcv.

I tried to use a standard CPVC plumbing fitting and had a heck of a time finding a tap bit that matched it. The threads/in on the tap bits did not match any of the fittings. I ended up having to buy a brass fitting that matched the threads of the CPVC fitting and tapping it by hand with a wrench. I couldn't find a "John Guest" fitting at the HWS maybe that was the issue. But anyways that is how I figured it out. It wasn't pretty, but it worked.

I'm planning to run plumbing down to a basement sump this weekend. The vertical drop from my overflow to the sump in the basement is roughly 10 feet. I'm expecting about 600 GPH of turnover if my return pump performs as expected.

I'm putting the ball valve in the full syphon pipe near the bottom, just above the sump. I'm considering adding a separate section in my sump for the three drains, with an over-under bubble trap and a cover, before the skimmer section. I'm considering this on the basis that with the 10 foot drop, the inflow of water into the sump will have substantial pressure and velocity. Enough to really churn up the inlet section of the sump? Am I right to be concerned about this? Or should I just run the drains into skimmer section and not worry about it?

I'm putting the ball valve in the full syphon pipe near the bottom, just above the sump. I'm considering adding a separate section in my sump for the three drains, with an over-under bubble trap and a cover, before the skimmer section. I'm considering this on the basis that with the 10 foot drop, the inflow of water into the sump will have substantial pressure and velocity. Enough to really churn up the inlet section of the sump? Am I right to be concerned about this? Or should I just run the drains into skimmer section and not worry about it?

Floyd R Turbo

Either busy or sleeping

You will only get the velocity of flow related to your input. With the pipe tuned to 80-90% of flow, this is all that can come back to the sump (480-540 GPH) through the siphon. With that long of a drop, it might take some time to purge the line and get the full siphon running, but once that takes over, then you've got a small % of flow through the open channel that will be skinning the pipe and that won't gain a ton of velocity for that reason.

Once the siphon is going, and the pipes have 'slimed up' as I call it, you won't even know there's water flowing. I run nearly 3000 GPH with no churning up of bubbles, I wouldn't sweat it.

Once the siphon is going, and the pipes have 'slimed up' as I call it, you won't even know there's water flowing. I run nearly 3000 GPH with no churning up of bubbles, I wouldn't sweat it.

uncleof6

Active member

I'm planning to run plumbing down to a basement sump this weekend. The vertical drop from my overflow to the sump in the basement is roughly 10 feet. I'm expecting about 600 GPH of turnover if my return pump performs as expected.

I'm putting the ball valve in the full syphon pipe near the bottom, just above the sump. I'm considering adding a separate section in my sump for the three drains, with an over-under bubble trap and a cover, before the skimmer section. I'm considering this on the basis that with the 10 foot drop, the inflow of water into the sump will have substantial pressure and velocity. Enough to really churn up the inlet section of the sump? Am I right to be concerned about this? Or should I just run the drains into skimmer section and not worry about it?

What pump, and where are you measuring the lift to? Usually a basement sump will come in around 14 - 16' dynamic head loss, after the plumbing is done.

What pump, and where are you measuring the lift to? Usually a basement sump will come in around 14 - 16' dynamic head loss, after the plumbing is done.

The pump is a Panworld 150PS, which I'm lead to believe is a rough equivelent to an Iwaki MD55. The reef central head loss calculator puts my dynamic head at about 15 feet, but the vertical drop from the overflow of my tank to the exit of the drains into the sump is about 10 feet. My basement doesn't have a high ceiling, and I've got my sump on as high a table as is comfortable in order to minimize the head. The calculator and performance table agree that I should have a flow of 800 gph, but I'm assuming that's optimistic.

Similar threads

- Replies

- 3

- Views

- 233

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 963