cant decide what I want to do and want to know what everyone is doing and what would you suggest.

I currently have a HOB overflow that I made for a 40 breeder but put on a 75gal DT, needless to say it is undersized but luckily so is my Mag7 so they are both at their max. I’m LQQKing at upgrading to a 120 (48x24x24) or a 150 (48x30x24H).

The stand when finished will work for either and the sump is a 36gal (about 26gal) but the first chamber is not big enough so I will need to build another one. I currently have some fish and corals so when I get everything ready it will be like a water change but change the sump and tank instead.

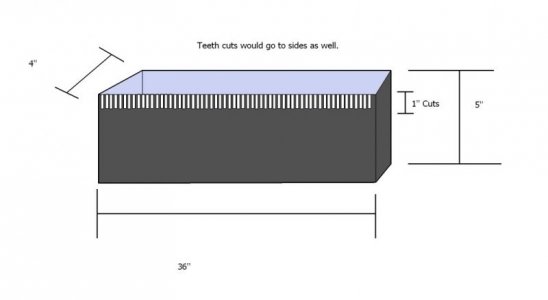

The tank will be viewed from 3 ¾ sides. When looking at the front of the tank it will have a small area in the back left side that will be the overflow area. My questions are what next? Do I do a bean animal, dorso or a herbie? There are a couple others that I have not named. I oringanly wanted to do a bean animal but I don’t have enough room and keep it out of site. The back of the tank will be in the kitchen side and have a couple of chairs at the counter for a small breakfast area. I will only have about 8” from the wall to the fridge to have pipes come from the side of the tank. I don’t know if the tank I get will have tempered bottom or not.

I have planned to do a C2C but was going to do it on the left side and let it drain beside the tank but don’t think this will work as the bean animal needs 3 pipes. If I don’t get a tempered bottom I could do a left corner OF and a dorso with an extra pipe for the emergency OF. The return can come up the outside of the tank into the canopy on the left side.

I have tried to use the Google sketch up and auto cad but I don’t have a clue how to use it. That’s about 3 hrs of time I won’t get back. I prefer to use the T-square and good o’pencil. I can do pretty good in excel (don’t laugh).

So let me know what your thoughts are. And I guess I’ll never get the hang of this 5 line rule.

I sorta have a durso on the HOB OF now. It’s 1-1/4 and I have ¼ tube in the top but have the tee sitting about 3/8 offset of the BH to keep the level where I want it. The ¼ tube then bends down so if it gets too full it will go to full siphon. When I put my PS (sea clone (will be replaced)) in the sump and the large filter sock it really was crammed and I was getting another PS so I made a remote sump behind the fridge. And to get the water out I have sorta a durso there as well and it dumps in the sump. Due to the extra area I tried it without using the filter sock and I’m pretty pleased. It is much quieter now than it was so it makes since after thinking about the horizontal distance as it had no horizontal run. The Bulk Heads I have are 1-1/4 thread on both sides.

The opposite side of the wall will be a viewing area in the living room. I guess I could do a triangle sorta. 2 pipes on the left side behind the fridge and 1 on the back and bend some Lexan and paint it to cover the pipe up.

I have LQQKed at a new 125 left corner OF by Marineland it only has 1 durso drain and the return in the corner. I could use the return as a second drain? They also told me that the 150 OF could be the same location. I’m not worried about the pvc pipe part as I can get it real cheap. And if I do the bean I could flip the sump and add about 20” on the horizontal run. As I have been thinking about sump on one side and fuge on the other with the pump in the middle.