budster.stig1

Broncoholic

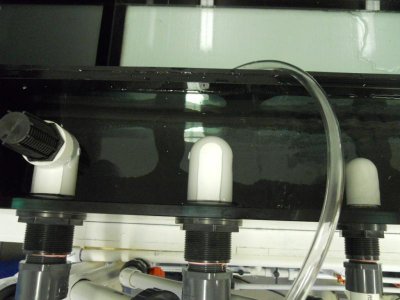

First off: cut the pipes off, so that the outlets are less than 1" below the water level in the sump. (basic setup instructions)

The siphon capacity of a 1" line is right around 2000 gph w/36" drop, which is right where this tank should be running. So, I think you should be running a larger siphon--rather than pushing the limits of your siphon line.

On your return pump performance: You have made some errors in the setup. First you are running the pump output right into a brick wall with the Tee attached to the back of the stand, and you have reduced the pipe diameter to 1" going up into the tank, and over into the sump it looks like. That is why you can't get any flow out of it. Too much friction loss, w/too many fittings and direction changes as well as too small a pipe diameter.

45 off of the pump outlet, over a bit, then 45 up to the tank, better would be to go straight up from the pump, eliminating the 45's in the upward run) and run the return up over the back of the tank. (yes I know you have a hole drilled, unfortunately it is too small for this pump) Tee off the line over to the sump. Keep the pipe size 1.5" entirely. Do not reduce it. For better performance increase the pipe size to 2".

Another problem with your pump plumbing is the 90° elbow right at the pump inlet. Sweep or not, this will cause a differential pressure (difference in velocity of the water entering the pump, between the inside of the curve and the outside of the curve) in the pump volute, that will cause the pump to cavitate. You need a straight run to the pump inlet ~ 7 - 10 times the pipe diameter.

Just an idle comment, I would not have wasted the money on a dart gold pump, rather a standard dart for this tank.

If my plans where to stay with just the DT and Fuge running off of the main pump I would have plumbed it as you suggest, however, I chose a manifold design for the main pump system because in the future I will add several other tanks (frag, and (2) more in wall DT's). My design was to utilize one pump instead of running several. The mistake I made was not sizing the pump with Reef-flo before ordering it. I talked with them today and they are going to "get my back" by replacing my Dart with a Hammerhead/Barrracuda Hybred, at no additional cost except shipping, It will be capable of creating higher pressure to move the amount of water necessary. All of your plumbing mods. recomendations I understand, however, Chriss at Reef-flo did not feel the sweep 90 at the inlet was a problem. The real world resides in my fish room and does not allow best case senario in all applications. Thanks for your in-put, do you have any suggestions on how to improve flow between sumps and sump and "fuge"? I'm not sure whether a larger diameter connection or just another 2" connection would be best...............Budster