uncleof6

Active member

Seems like I did it. I cut the 3 returns to just under the water level in the sump and now no more bubbles in the siphon and no more gurgles.:lol2:

I adjusted the siphon valve which is just above the sump to flow halfway and seems all the sound is gone and the sump is quieter too!!

Now all I hear is the water entering the overflow box, lol. I need to eliminate that. Any leads on that? Andofcourse the distant humming of the return pump.

Does making a slope in the overflow box help with that sound?

I can't thank you enough for strongly suggesting that I get the return pump below the sump! I can just imagine what would have happened by now.

Learning a lot of things.

Thank you!

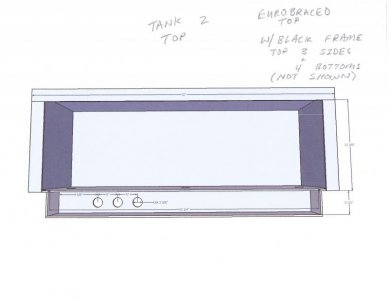

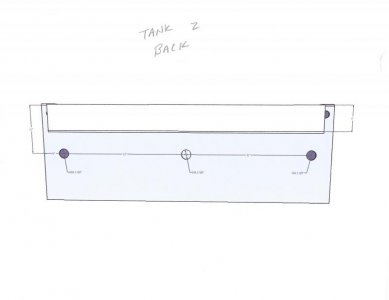

Are there teeth on the overflow? If so, cutting them off will help reduce the noise. That will also lower the water level in the main tank, not so good sometimes. The only other helpful solution to the noise is a shorter drop between tank water level and overflow water level, and a longer overflow box, adjust the height of the box, to maintain your water line, and no teeth.