One problem with the doubled rails idea is the drains from reef ready overflow boxes are often quite close to the plastic trim. If someone were to DIY the drains, both ideas work fine but for RR tanks, other considerations may take precedence. RocketEngineer

I built these 1.5" bigger than the depth of the tank, so while the tank sits flush on the front, it only sits on the inner 2X4 on the back, with some tiny fraction of the weight distributed by the 3/4" plywood shelf. The stand is also 3" wider than the tank, and there is about an extra inch to allow for tank frames and the variation between different tank manufacturers so the span is 73" and the width of the tank is 76". Reef ready boxes should be fine, if not a deeper shelf could be designed for that model of aquarium.

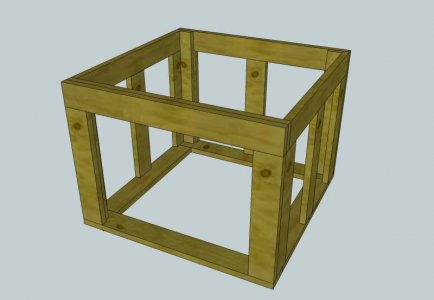

With regards to Dseg's stand as it relates to your design, you used two 2X4 sandwich rails (each rail being two 2X4s and a 1/2" plywood spacer).

RocketEngineer

The plywood is a solid piece, extending 3/4" below the bottom of the front rail, and is a bit more structural than just a spacer. Spacers could be random scraps.

In the picture your 275 pound weight is applied to the middle of a 72" span. Based on a 3.5" X 3.5" "beam" calculation, this point load deflects 0.086" (around 3/32"). On the other hand, a 180g tank weighs in at 1800 lbs distributed across the full 72" width and would sag 0.350" (slightly less than 3/8"). Personally, that is too much deflection for me.

RocketEngineer

I don't have a picture of me standing on the center rail while it's being lit up with the laser level. The closest is this one several steps further in construction of me sitting near the end. However even 1/32" would have shown up and did not. A composite beam with a MDO waterproof plywood core would be stiffer than a solid 4X4. I had the luxury of being able to physically check deflection and not have to depend on a table of values.

Also there are two rails, front and back so only half the tank weight is supported by the front one. Your figures probably already take that into account. Corner braces are later added to the tank so the 73" span is significantly reduced before the tank is installed.

However, going to 2X6 sandwich rails just like your design would span the 72" without a center brace just fine. To do the same with my design would require a 2X8 top frame.

RocketEngineer

I would rather just make bigger corner braces, even have the plywood core extend down behind the corner brace, on with a cabinet front covering it extend it down as a triangle like a gable end inverted, leaving room for a sump to slide in and out.

I will say that for smaller setups with owner drilled drains your 2X4 stand design is nice and ridged. In fact, as a stand without doors, making it from clear pine and coated with polyurethane it would look awesome. However, as the size increases the dimensions of the lumber needs to also increase to deal with the additional span and weight. Simple physics dictate that to keep the same deflection over increasing span and weight, the "beams" need to get bigger as well.

I will admit that my stand design is overkill. However, I'm an engineer by trade so being conservative is in my nature. I would rather have someone overbuild and be happy than have someone under build and end up with a leaking tank. Without knowing the particulars of each person's setup and their skills at woodworking, I can only provide advice based on the little information I have.

RocketEngineer

I've built in the past and still see a lot of wood stand built for aquariums in the style of yours but without the automated values for calculating what dimensions to use. Some of them greatly exceed in the size and amount of wood you have calculated, but it's still common for them to accordion over because bracing is absent or pops free. :reading:Your plans help people put the lumber they bought where it does good.

I also see stands made of plywood only, just this last weekend at an aquarium show about 500 tanks set up that way on plywood stands that interlock like Christmas tree ornament compartmentalized boxes without any nails or screws. There are things I like about both designs, so framing lots of plywood with 2by stock appeals to me. I get the stability of the plywood and the "beef" of the 2by.