QUESTIONS ABOUT MY SETUP. PLEASE HELP:

I know mine is a little different, but my fishroom is on the other side of the wall so I didn't have a choice.

Would like to get some thoughts on why it doesn't seem to be flowing as much as I would like. Some of you weighed in on bits and pieces earlier, but now that I've had some time with the system I have a pretty good idea of how it's working and can explain it all a bit clearer so we can try to work it out and get it performing as good as possible.

Basically, I plumbed my tank using the BeanAnimal setup but I did three things differently. For one, I ran straight through the wall before going into the sanitary tee and ball valve. This means there is about 8 extra inches of horizontal run that BeanAnimal doesn't normally have, straight out of the internal C2C overflow. Second, even after that, I don't have much straight vertical drop. I have just a little before going horizontal again and then some low slopes to the sump. And third, the drain pipes are 1" instead of 1.5". I don't normally like a lot of flow through my sump, typically keeping it at around 4-5x and that's probably where I am now. Thought I would save a few bucks on plumbing. But I feel like I should still be getting a lot more with this style setup. So I'm about to do what I should have done in the first place and redo all the drain plumbing with 1.5" the way the BeanAnimal was originally designed. I'll still have the horizontal runs and low slopes but I'm wondering if the larger diameter will make a difference? The main siphon drain does seem to be running as a siphon (no air), but if you put your hand under it in the sump it doesn't feel like that much more than the open channel that's letting air in. The difference I can feel on my hand is mostly the difference of the air bubbles coming out of the open channel pipe, verse the solid feeling column of water coming out of the siphon pipe. I would think it should be a much more noticeable difference? If you go back inside to the tank and plug the airline, that open channel does start flowing a lot more water and the level of water in the overflow drops. So I figure it's safe to assume that the main drain is purging the air from the lines and running as a siphon. But my startup seems different than everyone else's. When i start the pump, my overflow fills up and immediately goes right to it's normal working level. Everyone else's from what I heard has a few minutes of water running at a higher level, draining down the emergency drain, before the air purges from the main drain and starts flowing full siphon and drops back down. Mine doesn't do that at all.

I've read over Bean's website a thousand times, and from what I can tell everything else is set up the same. My drains end about an inch or two under the water surface of the sump. Any thing else you can think of? Do you think the size of the plumbing is the issue or something else? The system functions as it should with the emergency drains and all that, and it's flowing enough for what I need. I just expected A LOT more flow so I'd like to make any adjustments I can to maximize it, even if it still doesn't reach the proportions of the original design.

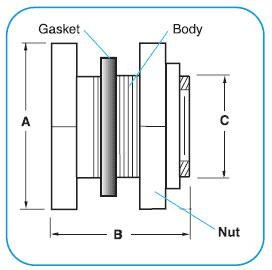

Pic below to give you an idea of what it looks like.

TIA!