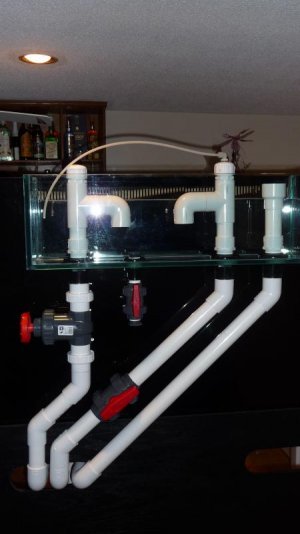

yes i didnt set it yet. i was going to lower all pipes but decided to leave it as is.once i glue everything i will tie it off at just above the dry pipe's hight 1/8" to 1/4"above should be good.i figured one would want the second siphon to begin as water just starts entering the dry pipe.but what would be the harm in lowering it to 1/4"below the dry pipe as long as it is still higher than the emergency pipe. should still work but earlier to start the second siphon before water enters dry pipe.or do you need water entering at least one pipe freely for this process to work properly.just asking why?thankx Uncle!!!

1/4" may not be enough. You need to test the system first and find out how high the water will go before the dry emergency will purge the overflow. It may be right on, or maybe not. Testing is a good thing.

If the open channel ( that is not the emergency pipe) trips to siphon before the main siphon starts, the main siphon will not start fully, defeating the system.

In normal operation at startup: water level rises, till the main siphon kicks in. Usually, the dry emergency will take some flow before the main siphon starts. After the siphon starts fully (all the air is purged,) using the valve on the siphon the water level in the overflow is raised, till water just flows in the open channel (the one with the air line.)

If, the air line is below the inlet to the dry emergency: water level rises, and instead of flowing in the dry emergency, the open channel trips to siphon mode (air line inlet submerged) and the main and open channel compete, and usually the main siphon will not fully engage, nor will the open channel fully engage. The system is defeated, and will not operate properly. Adjusting it can cure the issue, but on a restart, the system will not start properly.

There was some discussion on this topic a while back in this thread, and there are many variables that can cause a different outcome. However, in the interest of keeping with the theme of this thread "works as designed," and to keep consistency in information, it is recommended to keep the "trip order" as originally intended with the original design: with the open channel airline being submerged after the dry emergency is flowing. E.G. the airline inlet above the inlet to the dry emergency, with the open channel tripping to siphon as the "drop dead" fail safe. (both the main siphon and dry emergency fully plugged.)