You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silent and Failsafe Overflow System

- Thread starter JohnL

- Start date

uncleof6

Active member

I have not seen an external overflow drilled out the back, rather than the bottom. Doesn't really make any sense to do that......Drilling the back of a TANK, as opposed to the bottoms is the difference between only a little water on the floor, in the even of a leak--and the entire contents on the floor....

I have not seen an external overflow drilled out the back, rather than the bottom. Doesn't really make any sense to do that......Drilling the back of a TANK, as opposed to the bottoms is the difference between only a little water on the floor, in the even of a leak--and the entire contents on the floor....

I'm taking the back of the box, or the bottom of the box, not the tank...

uncleof6

Active member

I'm taking the back of the box, or the bottom of the box, not the tank...

Yes I know...

overexposed

Acroholic

Got my tank plumbed! I think I have the overflow tuned silent, but its hard to say because my return pump (magdrive 24) and plumbing are louder than my dishwasher! Literally - the tank is in my kitchen and it competes with the dishwasher for noise! Also, due to it being my first hole and not having technique down yet, the return hole ended up being nowhere close to where I originally intended. Its a few inches lower and further towards the center, so my tank backsiphons a TON of water. This unfortunately means that I have to run the sump with a very low water level.

After much research and thought it seems my biggest contributers to noise are the location of the pump in sump, the hard plumbing, and the shallow water. What I'll be trying today is replacing the hard plumbing will flexible pvc and moving the pump away from the corner of the sump, more towards the middle. As for the shallow water, I'm not sure how to address that besides a check valve? But i have heard that they can't be relied on...

After much research and thought it seems my biggest contributers to noise are the location of the pump in sump, the hard plumbing, and the shallow water. What I'll be trying today is replacing the hard plumbing will flexible pvc and moving the pump away from the corner of the sump, more towards the middle. As for the shallow water, I'm not sure how to address that besides a check valve? But i have heard that they can't be relied on...

uncleof6

Active member

In terms of the drain down problem, plumb the return in the tank up till the outlet is within 1" of the surface. Do not use lock line to accomplish this: it is not water tight. Things happen, such as mis-placed holes, but it is not horribly complicated to mitigate the issue. A 45° with a short extension should solve the issue. It may be a bit unsightly, but at this point the functionality is more important than aesthetics. I would not waste my day redoing the plumbing in spa flex, it is not going to help that much. Mags are just hot noisy pumps, and you would get ahead quicker by replacing the pump. A silicone filled pad under the pump, and silicone hose to isolate the inlet and outlet will make a difference. You will have to do some hunting around to find this stuff. Also this question is off topic for this thread. It would be better off in its own thread.

sinned-eel

New member

Hey bean,

Great setup. I have it on my tank but I cannot get the siphons to reprise after I shut off my return pump, simulating power outages. The overflow fills up to the emergency standpipe, but there is no siphon created with the main siphon pipe. I could turn the gate valve all the way to the left or right and it would not affect the water level in the overflow. There is some siphon in the standby pipe but not enuf to keep the return pump from spitting out air. Both siphon and standby pipes are fully immersed in the water. I would greatly appreciate your advice.

Great setup. I have it on my tank but I cannot get the siphons to reprise after I shut off my return pump, simulating power outages. The overflow fills up to the emergency standpipe, but there is no siphon created with the main siphon pipe. I could turn the gate valve all the way to the left or right and it would not affect the water level in the overflow. There is some siphon in the standby pipe but not enuf to keep the return pump from spitting out air. Both siphon and standby pipes are fully immersed in the water. I would greatly appreciate your advice.

FuzzyZipperbaum

New member

I haven't found it on this long thread but can you run an external protein skimmer with this design...? In order to do so you would need to have the 3 pipes join at some point before the skimmer....correct?

Dotterer

New member

I haven't found it on this long thread but can you run an external protein skimmer with this design...? In order to do so you would need to have the 3 pipes join at some point before the skimmer....correct?

Everything I've read in the thread suggests that both in order to maintain the failsafe part and to maintain the flow, you should have three separate drains into the sump.

darb85

New member

I fired this up and was having trouble with getting it tuned. I finally reached down and felt that the full syphon pipe isnt flowing much water and basicly only the open chanel is handling the water flow. I did notice that the full siphon pipe is a 1/4inish lower in the overflow than the open channel and terminates slightly lower than the open channel, is this enough to cause this? the pipe seems clean and clear.

Im at a loss. what did I do?

edit:

I stuck a ro line in the bottom and blew through it and the system suddenly started to work. IS this just start up blues are will it do this when ever I turn off the pump?

Im at a loss. what did I do?

edit:

I stuck a ro line in the bottom and blew through it and the system suddenly started to work. IS this just start up blues are will it do this when ever I turn off the pump?

Last edited:

Hudds

New member

Hi BeanAnimal,

I’m convinced of your system advantages over alternatives and I’ve decided to apply it to the aquarium I’m planning to build, with an external c2c overflow box on the smaller side of the tank.

I’ve got two questions, if you could help:

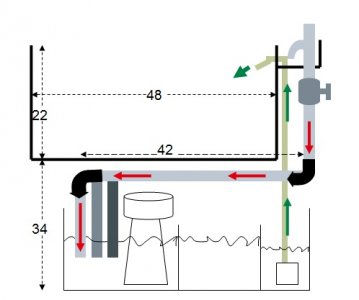

1) If I use one 90o corner and have the pipe horizontal traveling all the way (~42’’) below the DT and another 90o to lead it down to the sump, would that affect the silent and safe operation of the system? If so, what would you recommend? The same principle is to be applied to all 3 pipes. The reason why I’m thinking of this setup is to maximize the efficiency of the return pump, by having the shortest possible return pipe length.

2) If the return pipe exits into DT just below the water level (at one corner), would this return flow positioning create any issue with the proper operation of siphoning? If yes, what is the best placement in your opinion?

I’ve attached a simple drawing for your better understanding. Thank you in advance for your advice

I’m convinced of your system advantages over alternatives and I’ve decided to apply it to the aquarium I’m planning to build, with an external c2c overflow box on the smaller side of the tank.

I’ve got two questions, if you could help:

1) If I use one 90o corner and have the pipe horizontal traveling all the way (~42’’) below the DT and another 90o to lead it down to the sump, would that affect the silent and safe operation of the system? If so, what would you recommend? The same principle is to be applied to all 3 pipes. The reason why I’m thinking of this setup is to maximize the efficiency of the return pump, by having the shortest possible return pipe length.

2) If the return pipe exits into DT just below the water level (at one corner), would this return flow positioning create any issue with the proper operation of siphoning? If yes, what is the best placement in your opinion?

I’ve attached a simple drawing for your better understanding. Thank you in advance for your advice

Attachments

KindCorals

New member

Im having a custom tank built, which I have never done before and couldnt find much information on the actual size of the overflow. Can anybody please tell me if this sounds ok? I am going to follow BeanAnimal system with no mods.

The tank is a 4.5x2x18" tall and the C2C will be along the 2' side. It will be 6" tall by 4" deep with holes starting about 3.5" from the edge and about 3" from the top. Each hole is about 4" apart.

Should I make the overflow box itself 6x6" or do you think the 4" depth will be to short?

Thanks guys, I really appreciate it.

The tank is a 4.5x2x18" tall and the C2C will be along the 2' side. It will be 6" tall by 4" deep with holes starting about 3.5" from the edge and about 3" from the top. Each hole is about 4" apart.

Should I make the overflow box itself 6x6" or do you think the 4" depth will be to short?

Thanks guys, I really appreciate it.

had a couple questions...i plan on having an internal weir with external box. for those that have ran the open channel to feed the refugium part of your sump, is there enough flow from just the open channel or does it need to be also fed from the return?

if i do 1" bulkheads is there any advantage to use 1.25" fittings for the intakes? below the bulkheads i will use 1" on the siphon and i imagine emergency and 1.25" for the open channel. any problem with using just a straight pipe for the emergency intake (instead of a tee and 90)?

if i do 1" bulkheads is there any advantage to use 1.25" fittings for the intakes? below the bulkheads i will use 1" on the siphon and i imagine emergency and 1.25" for the open channel. any problem with using just a straight pipe for the emergency intake (instead of a tee and 90)?

uncleof6

Active member

Hey bean,

Great setup. I have it on my tank but I cannot get the siphons to reprise after I shut off my return pump, simulating power outages. The overflow fills up to the emergency standpipe, but there is no siphon created with the main siphon pipe. I could turn the gate valve all the way to the left or right and it would not affect the water level in the overflow. There is some siphon in the standby pipe but not enuf to keep the return pump from spitting out air. Both siphon and standby pipes are fully immersed in the water. I would greatly appreciate your advice.

I fired this up and was having trouble with getting it tuned. I finally reached down and felt that the full syphon pipe isnt flowing much water and basicly only the open chanel is handling the water flow. I did notice that the full siphon pipe is a 1/4inish lower in the overflow than the open channel and terminates slightly lower than the open channel, is this enough to cause this? the pipe seems clean and clear.

Im at a loss. what did I do?

edit:

I stuck a ro line in the bottom and blew through it and the system suddenly started to work. IS this just start up blues are will it do this when ever I turn off the pump?

Both these issues are the same issue actually. The siphon is not starting, or not completely starting. Most of the time, this is due to a setup flaw and/or deviation from the original design.

Things to look for:

1) Pipes terminate more than 1" below the water level in the sump. (can't purge air from siphon line)

2) Horizontal runs in the drain lines. (air-lock--air trapped in the line)

Those are the most common issues with starting. Some not so obvious:

1) Air leak in the siphon line. (Prevents the siphon from becoming a siphon.)

2) Open channel air inlet line too low in the overflow. (open channel trips to siphon, before the main siphon purges all the air out.

In all cases, the system functions well as designed. If you change the setup (alter the design that has been presented) your mileage may be somewhat less than what is expected from "as designed."

One thing, is the placement of the open channel in relation to the siphon. I have not seen any advantage at all to placing the open channel higher than the siphon. Starting issues are invariably due to modifications of the original design, or poor assembly. (air leaks) Although placing the open channel higher, can really hurt, I have not yet found a reason to do so.

uncleof6

Active member

Hi BeanAnimal,

I'm convinced of your system advantages over alternatives and I've decided to apply it to the aquarium I'm planning to build, with an external c2c overflow box on the smaller side of the tank.

I've got two questions, if you could help:

1) If I use one 90o corner and have the pipe horizontal traveling all the way (~42'') below the DT and another 90o to lead it down to the sump, would that affect the silent and safe operation of the system? If so, what would you recommend? The same principle is to be applied to all 3 pipes. The reason why I'm thinking of this setup is to maximize the efficiency of the return pump, by having the shortest possible return pipe length.

2) If the return pipe exits into DT just below the water level (at one corner), would this return flow positioning create any issue with the proper operation of siphoning? If yes, what is the best placement in your opinion?

I've attached a simple drawing for your better understanding. Thank you in advance for your advice

Sorry, I missed clicking your post. Looking at your design, you are setting yourself up for the same issues I addressed in the above post.

Horizontal runs can, and do, cause the siphon to air-lock (air trapped in the line) and the system will not start properly. It is advised to keep ALL the drain lines angled down. 45° or more is preferred.

uncleof6

Active member

had a couple questions...i plan on having an internal weir with external box. for those that have ran the open channel to feed the refugium part of your sump, is there enough flow from just the open channel or does it need to be also fed from the return?

if i do 1" bulkheads is there any advantage to use 1.25" fittings for the intakes? below the bulkheads i will use 1" on the siphon and i imagine emergency and 1.25" for the open channel. any problem with using just a straight pipe for the emergency intake (instead of a tee and 90)?

No, there is not enough flow through the open channel (if the system is operating--and tuned properly--to run anything at all. It is well advised to have all three of the pipes terminate in the same section of the sump (equal water level) and don't mess with the drain system by trying to have it do more than it is designed to do: drain water from the tank. The drain systems, (none of them,) are not intended to feed accessory equipment. Folks cut corners, and end up with problems--more often than not.

Accessories should be run from a branch in the main return line; the physics are less temperamental.

Hudds

New member

Sorry, I missed clicking your post. Looking at your design, you are setting yourself up for the same issues I addressed in the above post.

Horizontal runs can, and do, cause the siphon to air-lock (air trapped in the line) and the system will not start properly. It is advised to keep ALL the drain lines angled down. 45° or more is preferred.

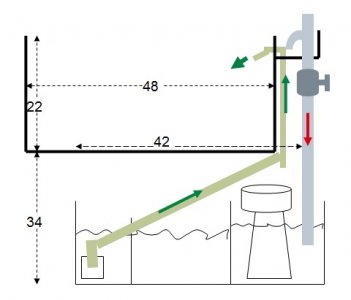

Thank you uncleof6 :thumbsup:

I'll have them all 3 straight down the sump, no angles at all.

I'm sacrificing return pump's efficiency like that, but hey, you can't hav'em all

Attachments

thanks for the response uncle! i saw a few people that did it so i figured i would ask.No, there is not enough flow through the open channel (if the system is operating--and tuned properly--to run anything at all. It is well advised to have all three of the pipes terminate in the same section of the sump (equal water level) and don't mess with the drain system by trying to have it do more than it is designed to do: drain water from the tank. The drain systems, (none of them,) are not intended to feed accessory equipment. Folks cut corners, and end up with problems--more often than not.

Accessories should be run from a branch in the main return line; the physics are less temperamental.

any comments about the fittings for the intake in the external box?

uncleof6

Active member

Thank you uncleof6 :thumbsup:

I'll have them all 3 straight down the sump, no angles at all.

I'm sacrificing return pump's efficiency like that, but hey, you can't hav'em all

Up-size the return plumbing size, and that will make up for the additional length of the run, as well as the 45°'s;. If the return pipe size ends up larger than the pump intake plumbing size, up-size the pump suction line as well.

KindCorals

New member

Up-size the return plumbing size, and that will make up for the additional length of the run, as well as the 45°'s;. If the return pipe size ends up larger than the pump intake plumbing size, up-size the pump suction line as well.

If the return pump has 3/4" plumbing and you make it 1", would that be enough or would you recommend going all the way up to 1.5"?

Similar threads

- Replies

- 3

- Views

- 180

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 813